Blasting method for shallow-buried goaf of strip mine

A goaf and open-pit mine technology, applied in blasting, mining equipment, earthwork drilling, etc., can solve the problems of irregular mining of underground goafs, deep subsidence pits, mining equipment and personnel safety threats, etc., to reduce The amount of manual filling and leveling works, the construction safety environment is good, and the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

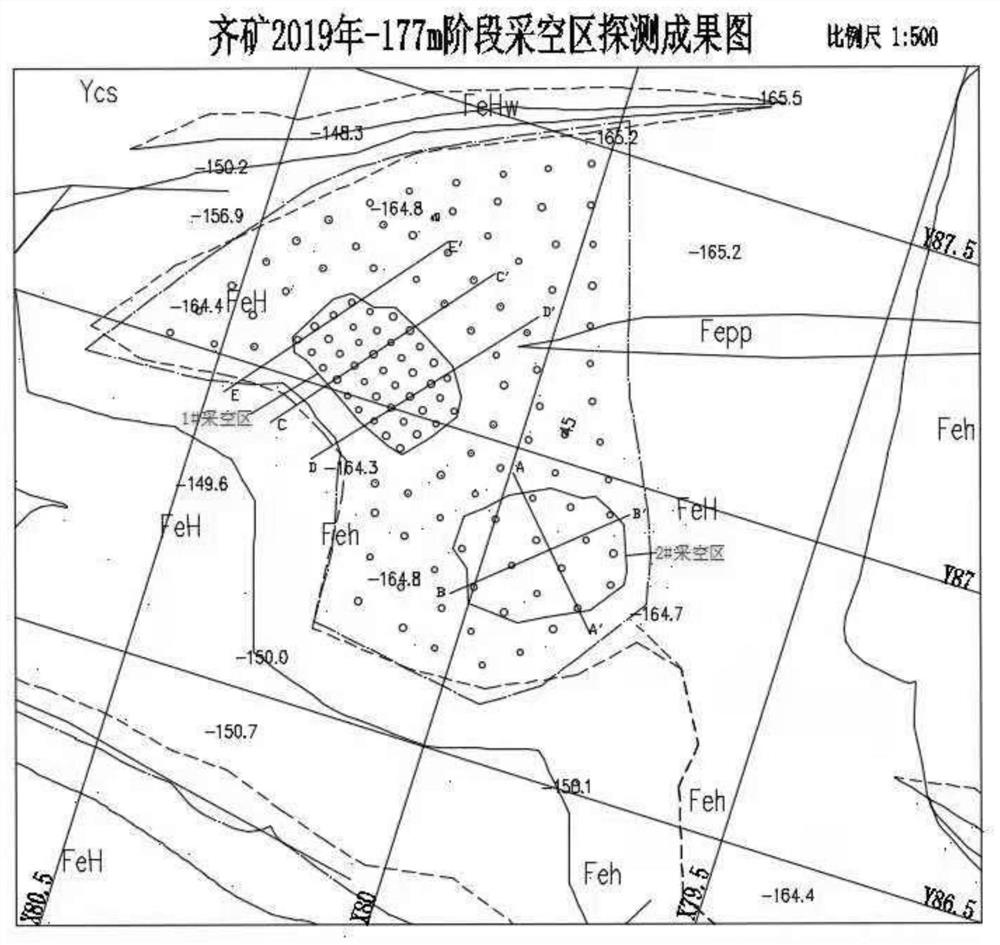

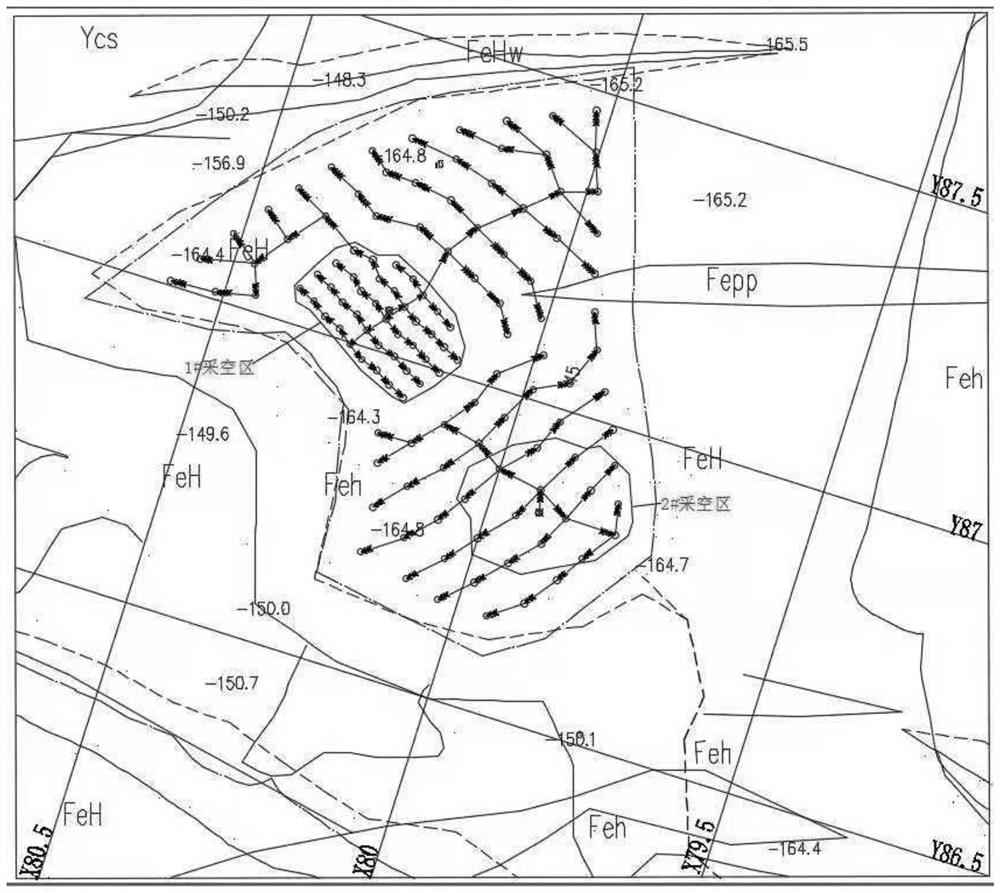

[0119] Qidashan Iron Mine -177m stage mined-out area blasting collapse design scheme:

[0120] The goaf processing blasting task goaf is located at the northern end of the -177m stage of Qi Mine, coordinates: y-8650~y-8750; x-7950~x-8050 area, according to the obtained detection data, at this stage the ore Two goafs were detected in the production site, namely Ⅰ# and Ⅱ# goafs. With the advancement of the stope working face, according to the mine production organization arrangement and the reality that the existing stope space is limited, the main transport road of the stope after the relocation will cross the upper part of the goaf. Effective governance will have brought a major threat to mine safety production.

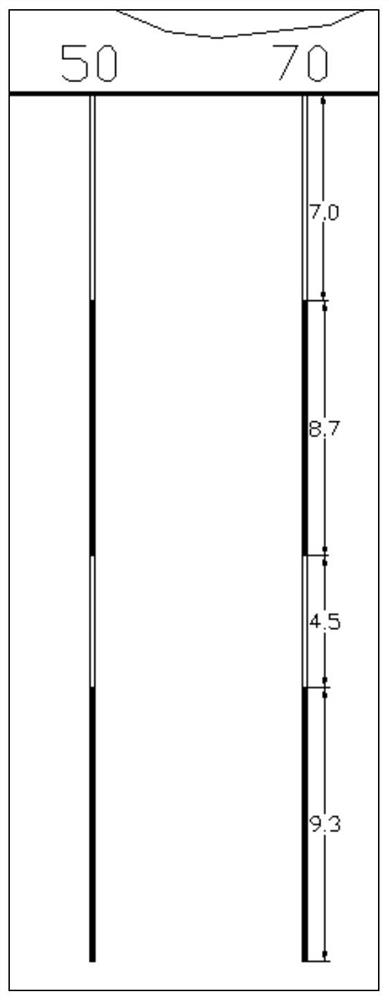

[0121] Step 1. The ore body in this area is a large-scale thick-bedded ore body with a stable occurrence, a strike of 310°-340°, a strike extension of 4.6 kilometers, a dip angle of 70°-85°, a dip of 70° to 85°, a dip in the south-west or northeast, and a dip in dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com