Tunnel Construction Method Crossing Earth-rock Boundary Strata

A technology for tunnel construction and tunneling, which is used in tunnels, earth-moving drilling, tunnel lining, etc., can solve problems such as deformation and structural damage of initial support arches, deformation of tunnel face support, and collapse of upper soil layers, etc. The effect of stable ability, close process connection and saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

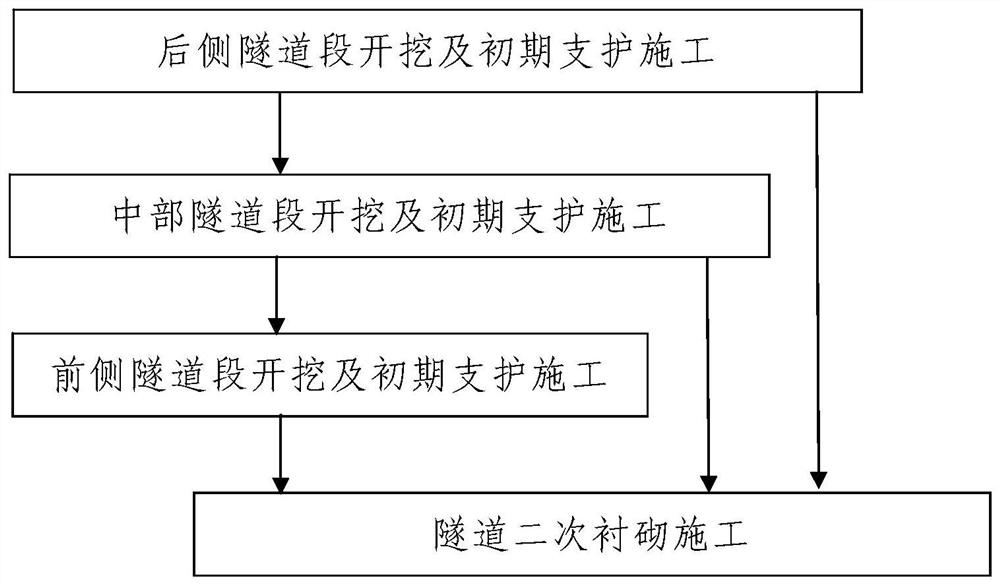

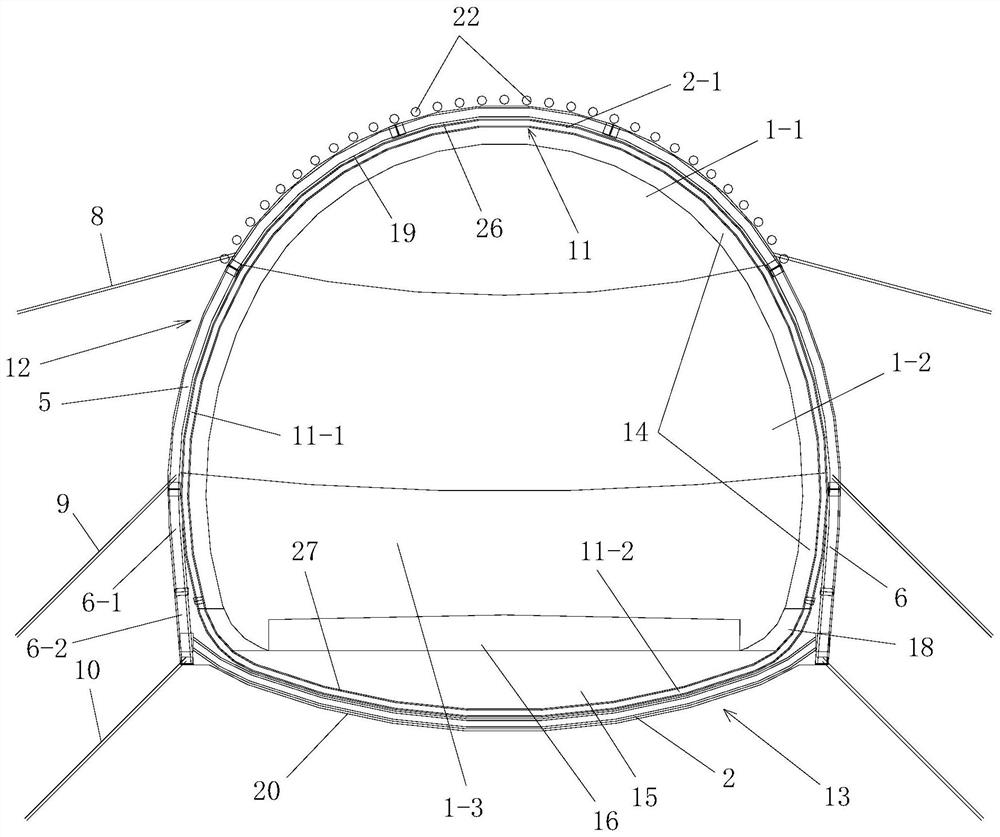

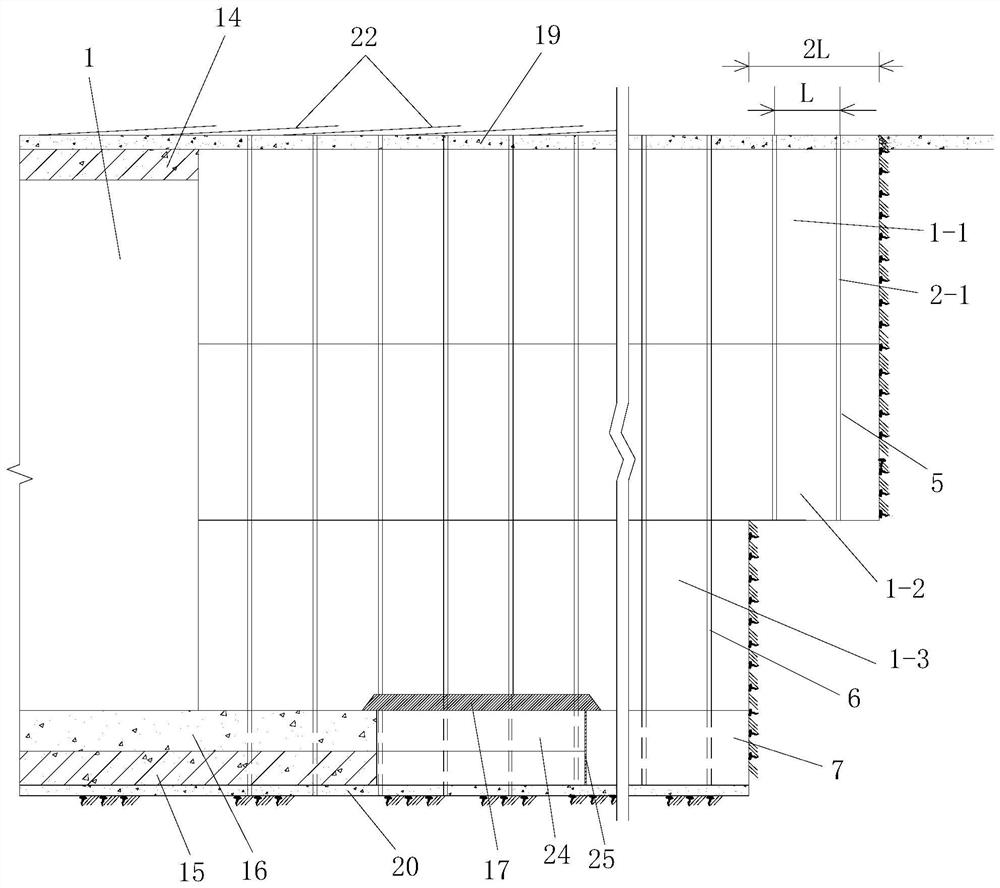

[0145] Such as figure 1 Shown is a tunnel construction method that crosses the soil-rock boundary stratum, and the tunnel to be constructed has a cross-section greater than 100m 2 And for the shallow buried tunnel located in the soil-rock boundary stratum, the surrounding rock level of the tunnel hole 1 in the constructed tunnel is grade IV or grade V; Figure 7 , the soil-rock boundary stratum includes a loess layer 3 and a rock layer 4 below the loess layer 3, and the interface between the loess layer 3 and the rock layer 4 is an earth-rock interface; the tunnel hole 1 of the constructed tunnel is divided from top to bottom It is an upper cave body 1-1, a middle cave body 1-2 and a lower cave body 1-3. The upper cave body 1-1 is a cave body formed after excavating the upper steps of the constructed tunnel from back to front, The middle cave body 1-2 is a cave body formed after excavating the middle steps of the constructed tunnel from the back to the front, and the lower ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com