Excavating method for jump-digging of double-side wall guide pit combined arch part of tunnel

A double-side-wall pilot pit and tunnel technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the phenomenon of stress concentration at the entrance of the tunnel, which is complex in force, does not consider the space effect of the tunnel soil, and is difficult to control the stability of surrounding rocks, etc. problems, to achieve the effect of reducing disturbance and deformation of the surrounding rock, facilitating the stability of the surrounding rock, and improving the excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The design features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through the embodiments, so as to facilitate the understanding of those skilled in the art:

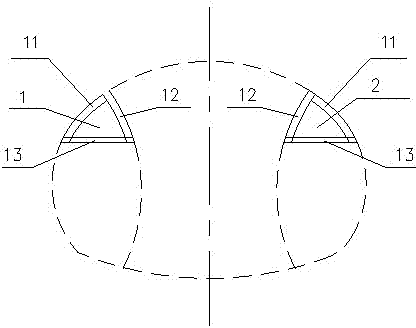

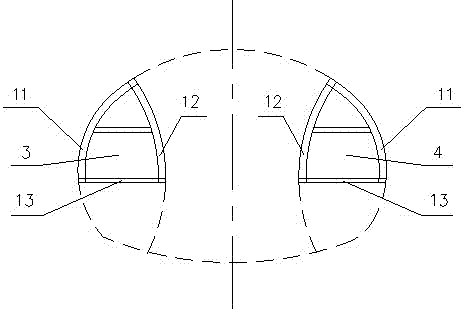

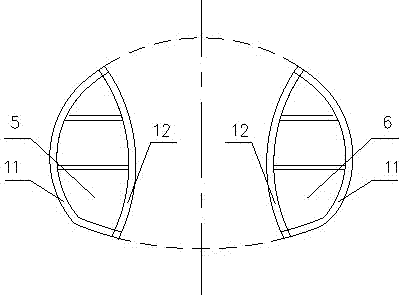

[0024] attached Figure 1-12 The marks 1-20 represent the left upper pilot pit 1, the right upper pilot pit 2, the left middle pilot pit 3, the right middle pilot pit 4, the left lower pilot pit 5, the right lower pilot pit 6, Arch center pilot pit 7, arch side pilot pit 8, upper core soil 9, lower core soil 10, side pilot pit initial support 11, measuring pilot pit temporary support 12, horizontal joint 13, middle pilot pit column 14, Arch primary support 15, inverted arch initial support 16, side wall secondary lining 17, inverted arch secondary lining 18, mid-pit cross brace 19, arch secondary lining 20.

[0025] Such as Figure 1-10 As shown, the long-span tunnel in this embodiment refers to a tunnel with a height-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com