Micro-disturbance mechanical separate tunneling construction method for tunnel in weak surrounding rock

A technology of weak surrounding rock and micro-disturbance, applied in the direction of tunnels, tunnel linings, shaft linings, etc., can solve problems such as insufficient support strength, cracking, collapse and roof fall, secondary linings, etc., to reduce disaster losses, prevent deformation, and control large-scale The effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

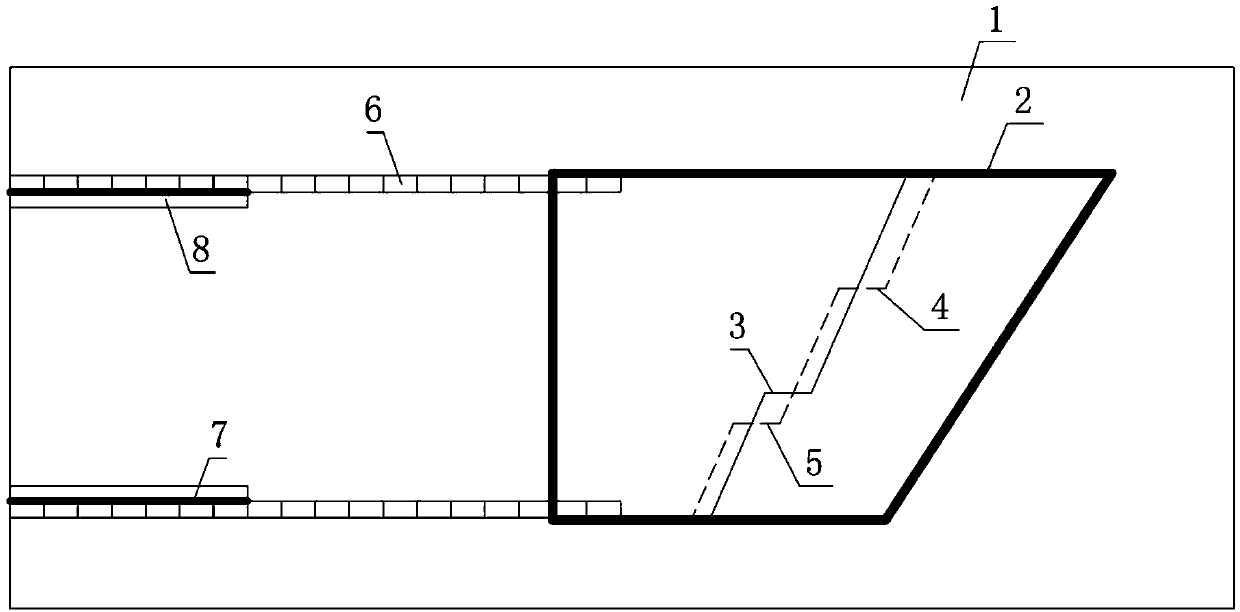

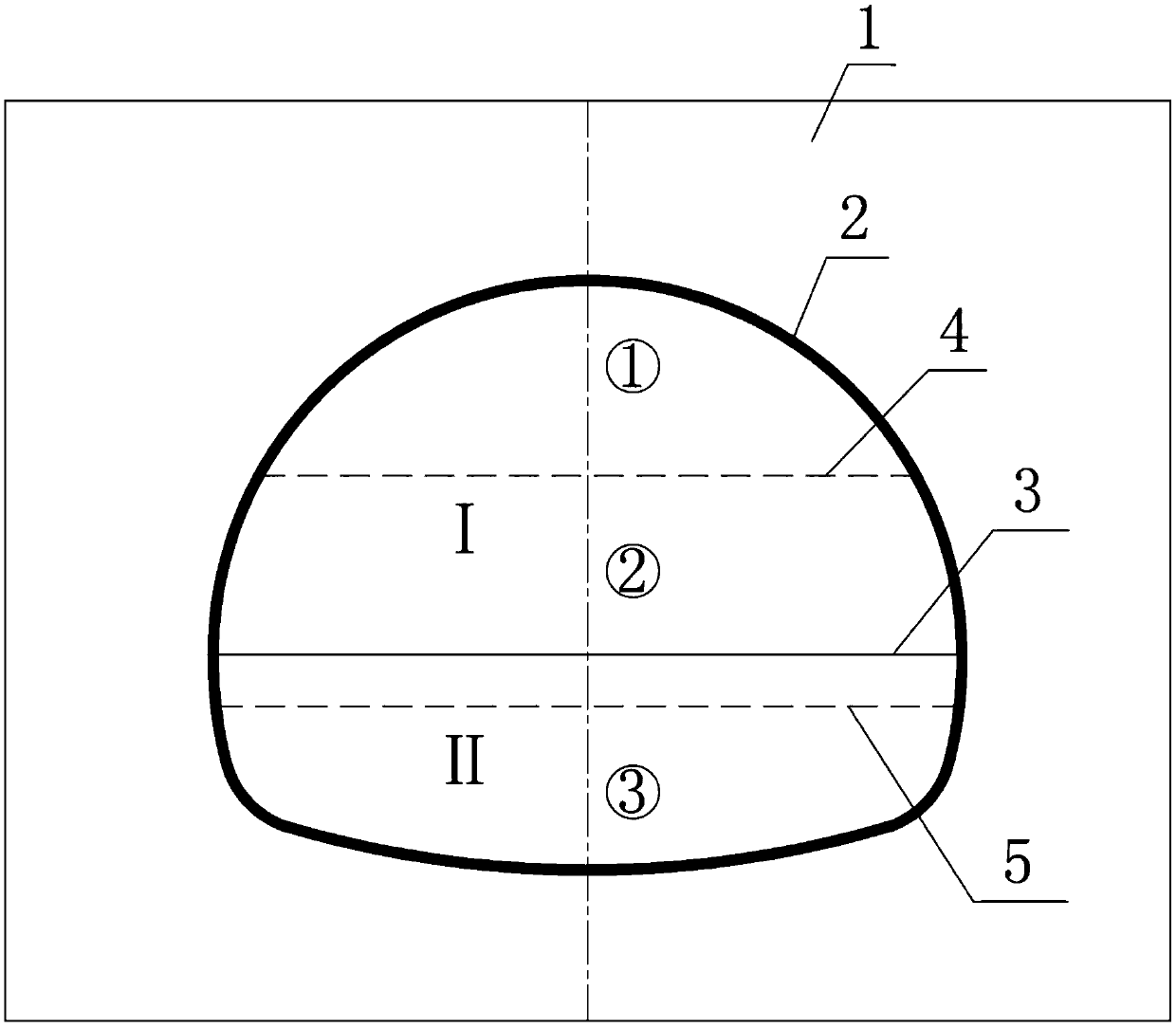

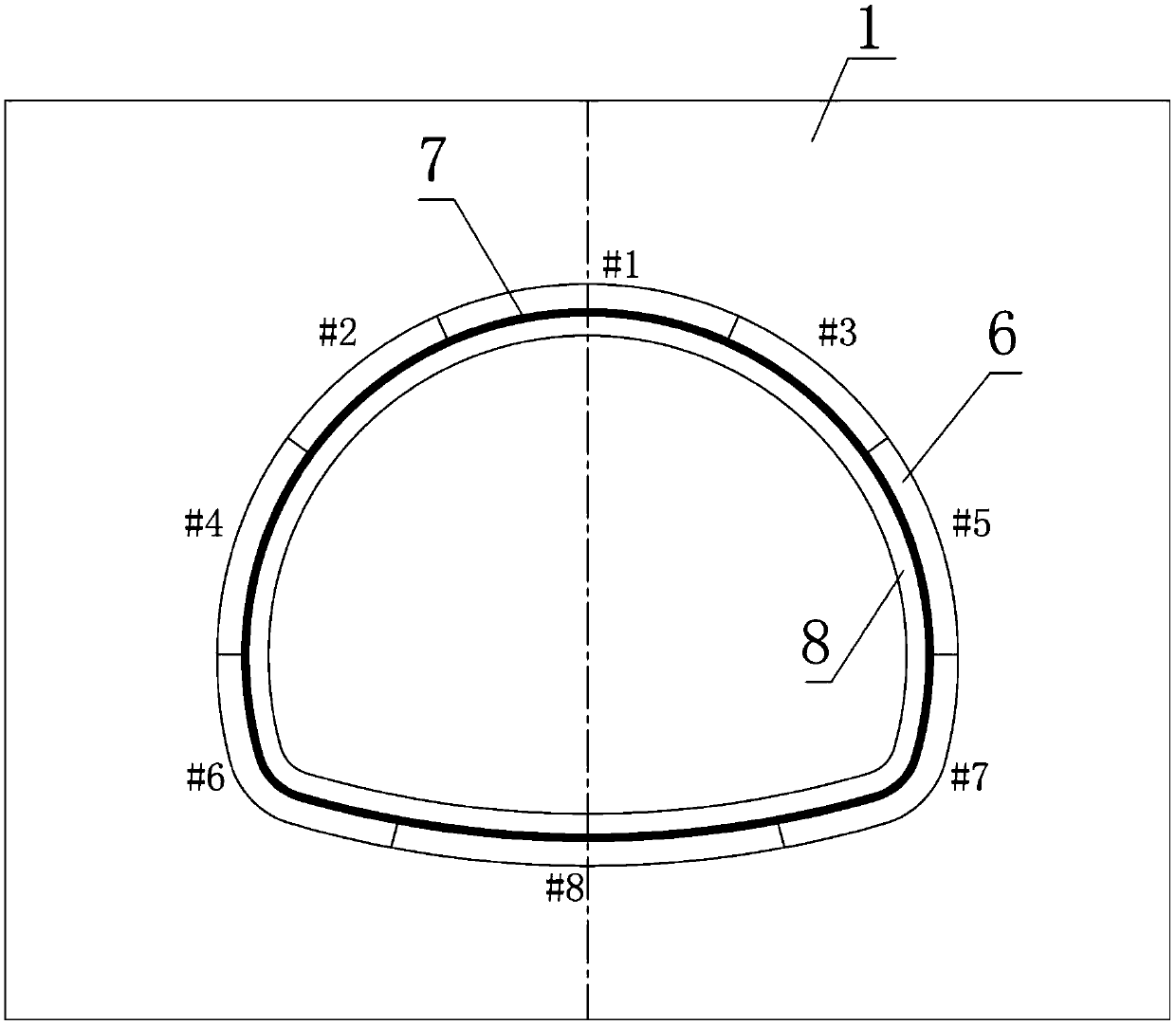

[0036] Such as Figure 4 and 5 As shown, in a micro-disturbance segmental mechanical excavation method for weak surrounding rock tunnels, the complete cycle steps of a jacking process are as follows:

[0037] Step 1. Shield division jacking

[0038] Divide the shield 2 of the annular closed structure into multiple sub-shields from top to bottom. For the convenience of advanced jacking, the level difference between the top and bottom of the shield is 1 / 2 of the shield height;

[0039] High-strength drill pipes are used to eliminate the boulder obstacle in front of the shield, and the shield 2 is pushed into the surrounding rock 1 through a hydraulic jack. The jacking footage of the shield 2 is 1.2m. The upper sub-shield is inserted into the surrounding rock 1, and then the other sub-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com