Cave system differential surge chamber

A surge chamber, differential technology, applied in engine components, greenhouse gas reduction, machines/engines, etc., can solve the problems of long surge wave attenuation period, affecting the power supply quality of the unit, and large surge surge amplitude in the surge chamber. , to achieve the effect of improving the flexibility of power station operation and scheduling, improving the quality of power supply, and reducing the amount of engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

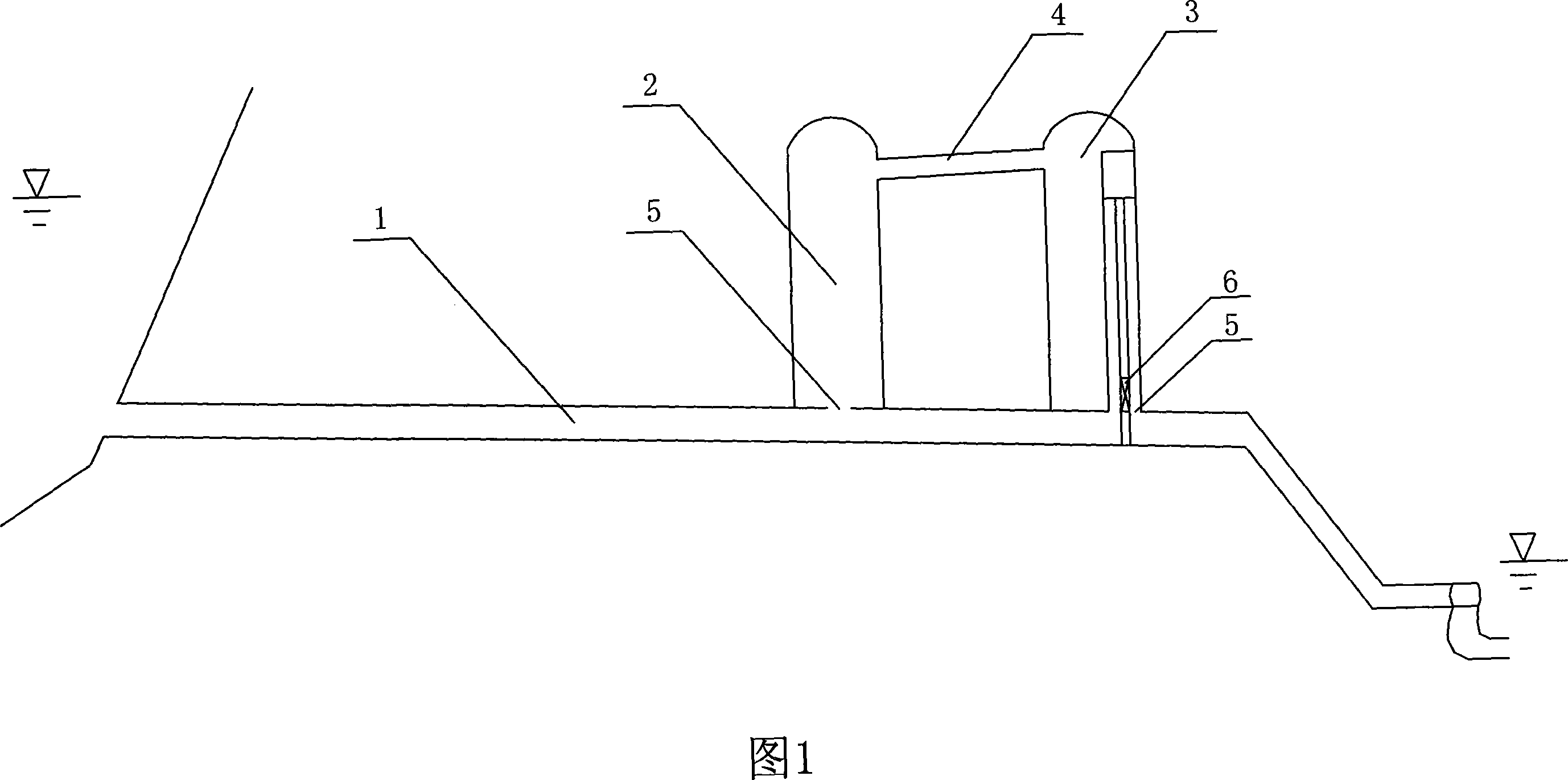

[0024] As shown in Figure 1, the surge chamber of a long diversion hydropower station with medium and low water head and large flow has a large stable area due to the low power generation head and long tunnel line, large surge amplitude, and long wave attenuation time When a single large-scale surge chamber cannot be arranged due to geological conditions, hub layout, etc., 2 to 4 smaller-scale surge chamber groups can be arranged in series at the end of the long water diversion tunnel 1, and the distance between the surge chamber groups meets Surrounding rock stability or hub layout requirements, and arrange upper room connecting holes between the surge room groups to form a differential effect to achieve the purpose of suppressing the surge amplitude and accelerating the attenuation of surge fluctuations.

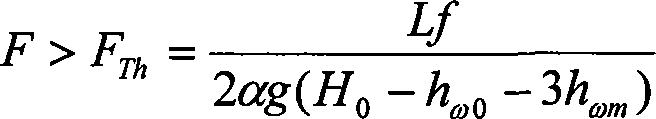

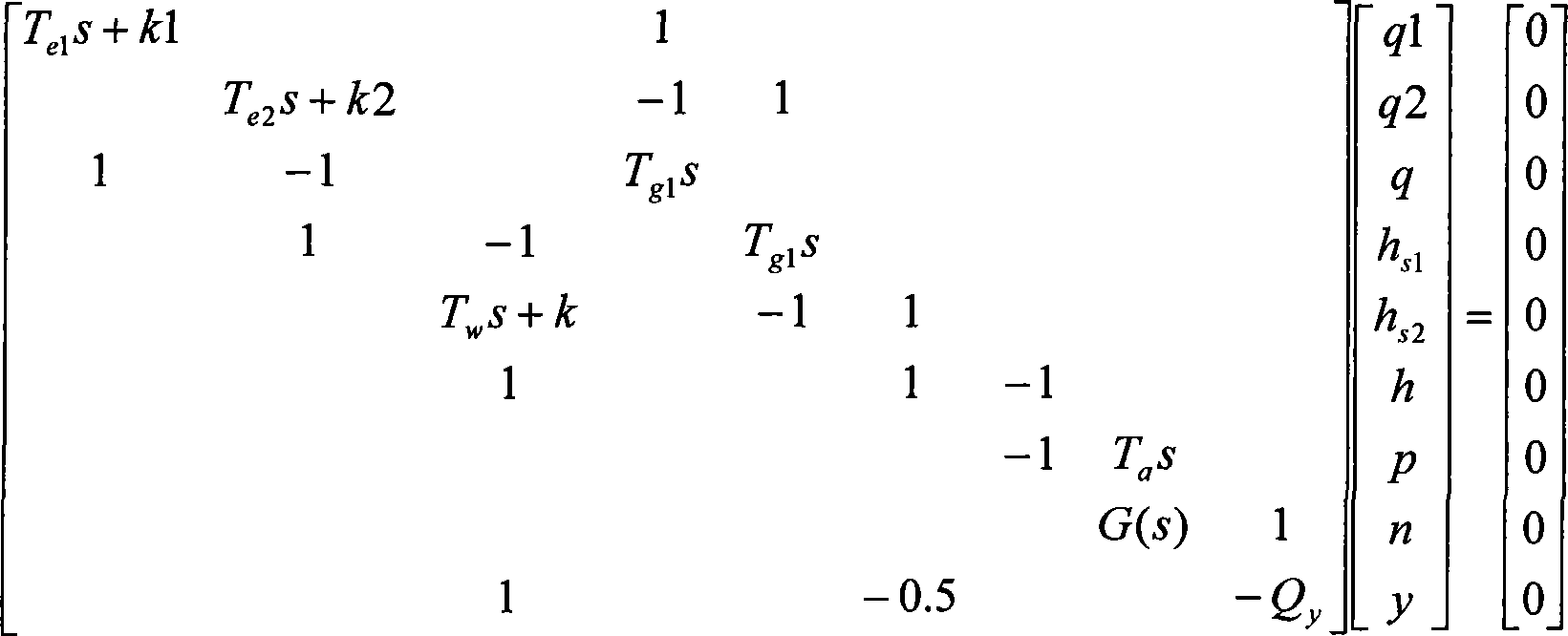

[0025] The surge chamber group in this embodiment is two impedance type underground surge chambers arranged in series. The first step is to determine the area of the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com