Tunnel IV-type and V-type surrounding rock advanced tied arch damping reinforcing method

A technology for tunnels and rod systems, which is applied to the shock-absorbing reinforcement method of advanced rod system arches in Category V surrounding rocks and Category IV tunnels. It can solve the problems of non-reinforcement, heavy front and rear beam supports, and limited effect, so as to prevent creep damage. , Stabilize the surrounding rock and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

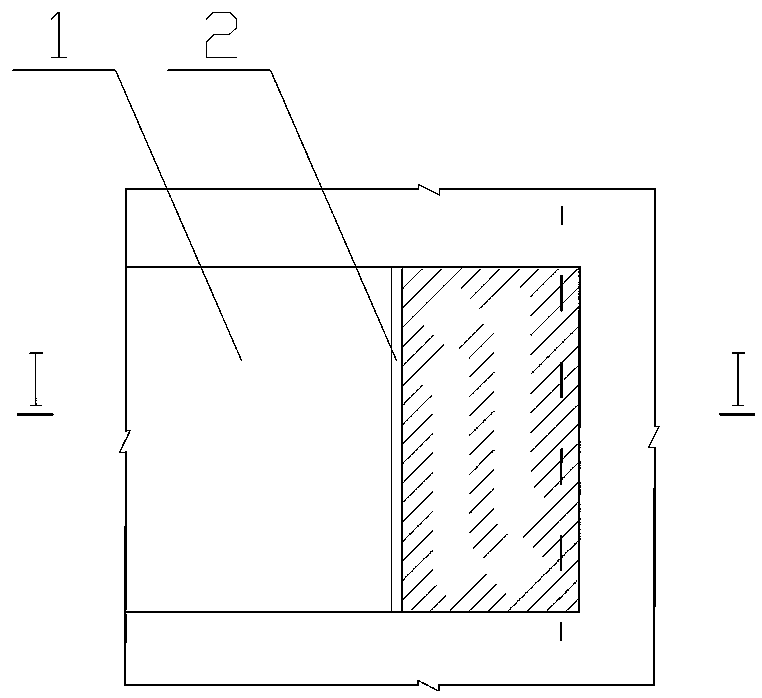

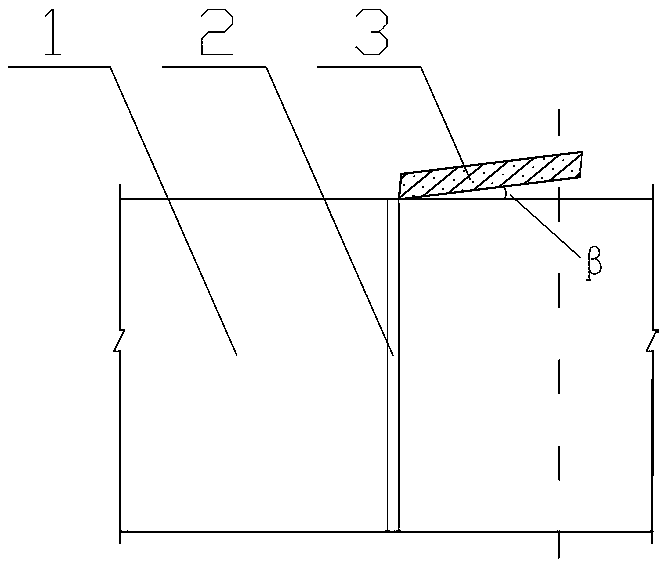

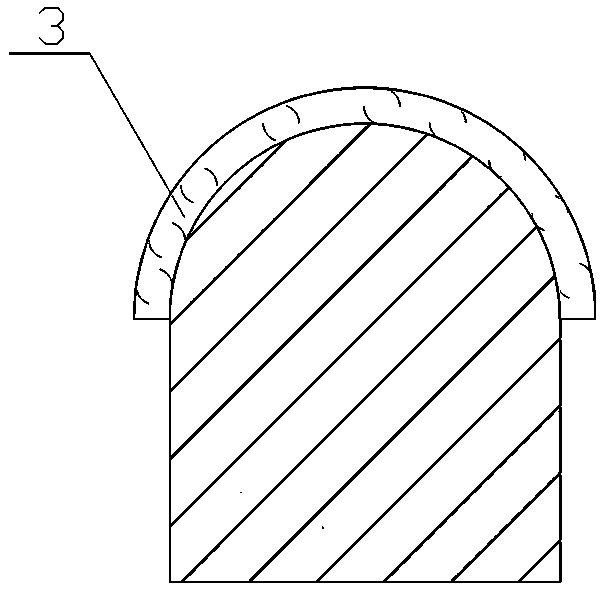

[0024] Such as Figure 1-9 As shown, the tunnel IV and V category surrounding rock shock-absorbing and reinforcing method of advanced bar system arch in the present invention comprises the following steps:

[0025] In the first step, a steel arch 2 for supporting the exposed rock mass is erected on the face of the tunnel 1 according to conventional methods to ensure the safety of subsequent construction.

[0026] The second step is to excavate an arched advanced thin-walled groove 3 with a central angle of 180° on the top of the tunnel face. The groove height of the arched advanced thin-walled groove 3 (refers to the distance between the top wall and the bottom wall of the groove ) is 200-260mm, the excavation depth is 2000-3500mm, and the arched advanced thin-walled groove 3 is along the excavation direction at an angle β of 2-5° (see figure 2 ) expand outward. When the arch-shaped advanced thin-walled groove 3 is excavated, it should be excavated by manual mechanical dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com