Large-deformation self-adaptive energy release anchor rod

An adaptive, large-deformation technology, applied in the installation of bolts, construction, excavation, etc., to achieve the effect of releasing energy, good support, and improving early support capacity and failure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0018] In the present application, in order to clearly describe the structural features of the present invention, the orientation words "front" and "rear" are used. The location close to the exit of the surrounding rock.

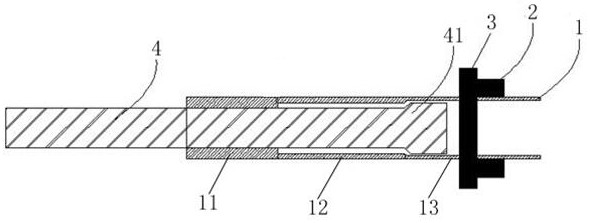

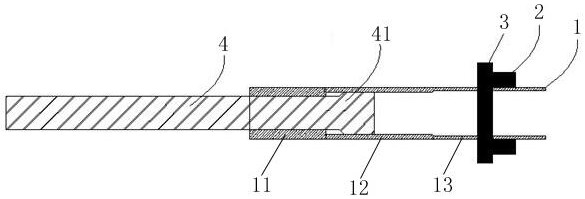

[0019] like figure 1 and figure 2 As shown, this embodiment includes a rod body 4, and also includes an inner stepped tube 1 sleeved on the rear section of the rod body 4. The tail of the rod body 4 is a wear-resistant magnesium alloy friction head 41; the inner stepped tube 1 has two steps On the surface, the inner stepped tube is divided into small-diameter tube 11, first-stage medium-diameter tube 12 and large-diameter tube 13 from front to back; the outer diameter of wear-resistant magnesium alloy friction head 41 is slightly larger than the inner diameter of medium-diameter tube 12 , the wear-resistant magnesium alloy friction head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com