Waterproof and drainage system and construction method of low-medium radioactive waste grotto type disposal site

A technology of drainage system and construction method, applied in the field of nuclear power, can solve problems such as ineffective water isolation, and achieve the effect of reducing nuclear radiation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

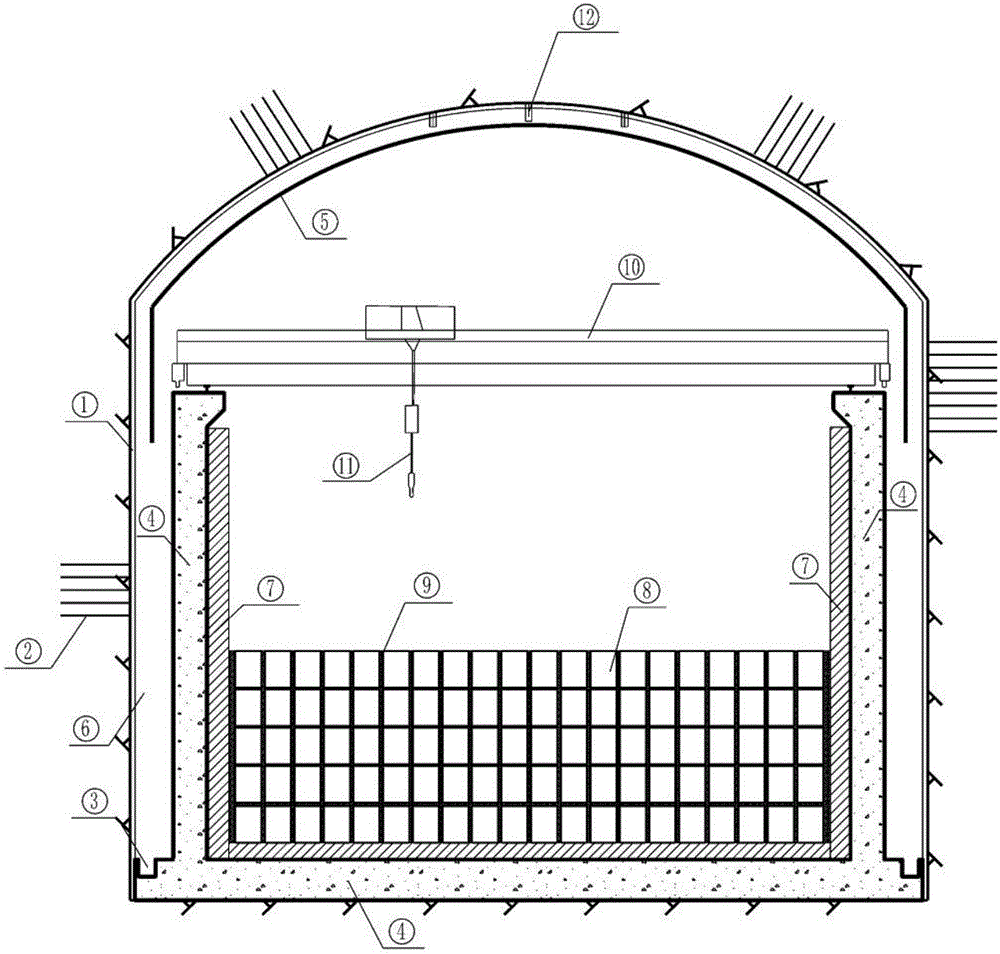

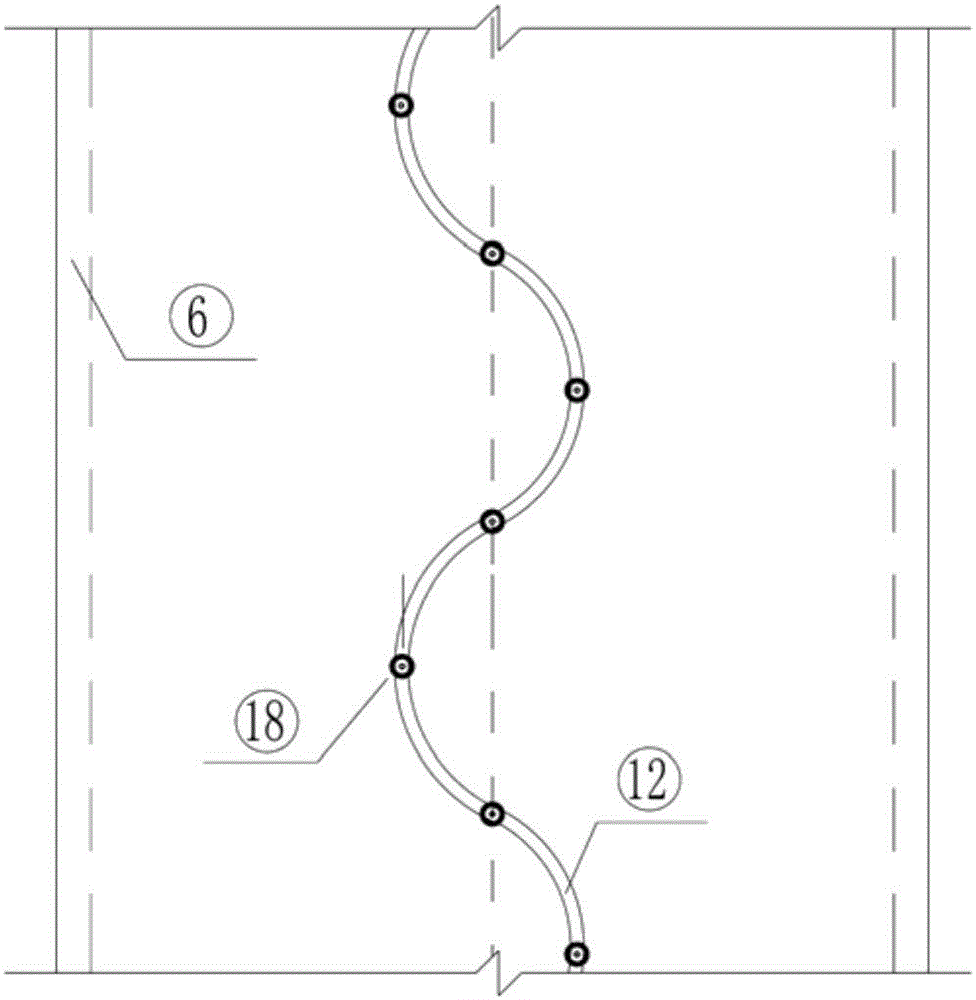

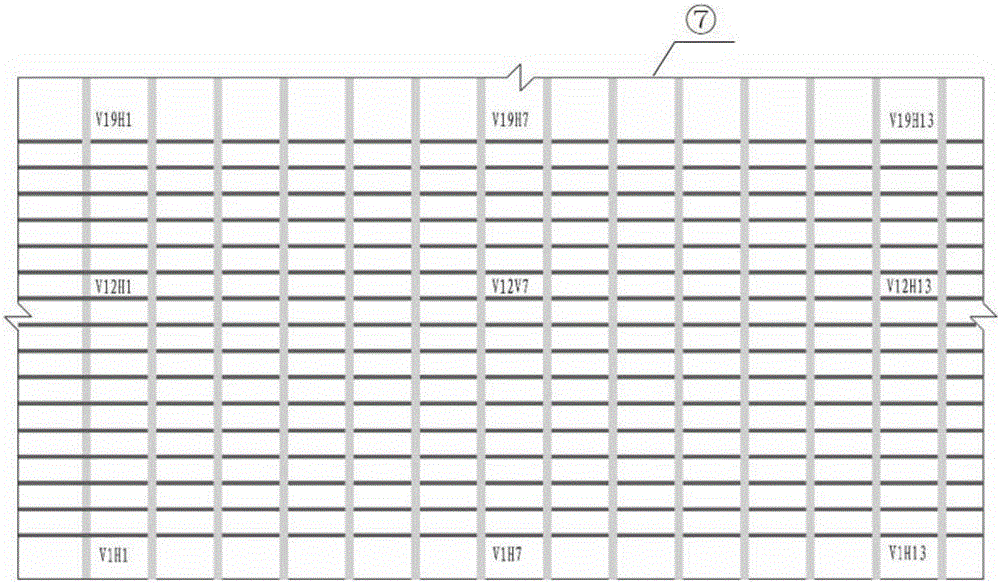

[0067] The waterproof and drainage system of the cavern type disposal site for low and intermediate radioactive waste of the present invention is located in the cavern, the cavern inner wall is provided with cave wall spraying protection 1, and the cavern inner wall fissure is provided with fissure sealing 2. refer to Figure 1 ~ Figure 3 , the system includes the anti-seepage side wall and the bottom plate 4 of the U-shaped concrete frame structure, and the two sides of the anti-seepage side wall and the bottom plate 4 are out of contact with the wall of the excavated cavern, so as to avoid secondary cracking of the concrete structure caused by the deformation of the rock mass. The frame structure is used as a storage space for radioactive waste barrels, and as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com