Pre-stress anchor cable structure applicable to underground powerhouse rock wall crane beam portion

A technology of prestressed anchor cables and crane beams, applied in underwater structures, infrastructure engineering, buildings, etc., can solve the problem of increasing the deformation of the crane beams on the rock wall, unfavorable stability of the crane beam structure on the rock wall and the surrounding rock of the underground powerhouse, Increase the rock wall crane beam bolt load and other issues to achieve the effect of a complete support system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

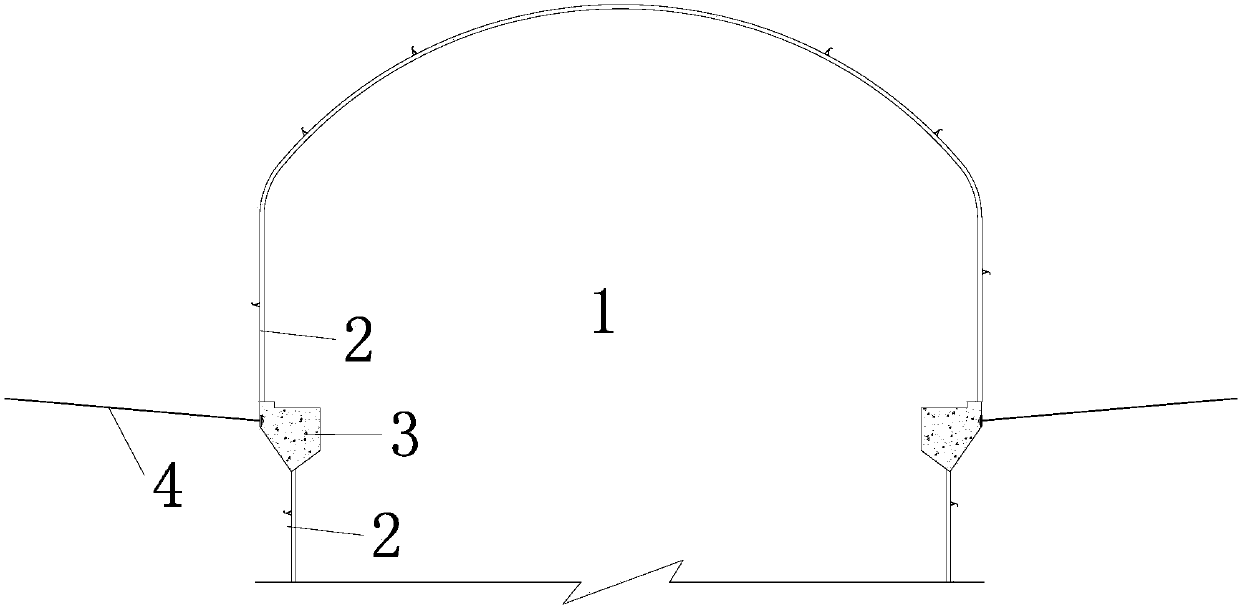

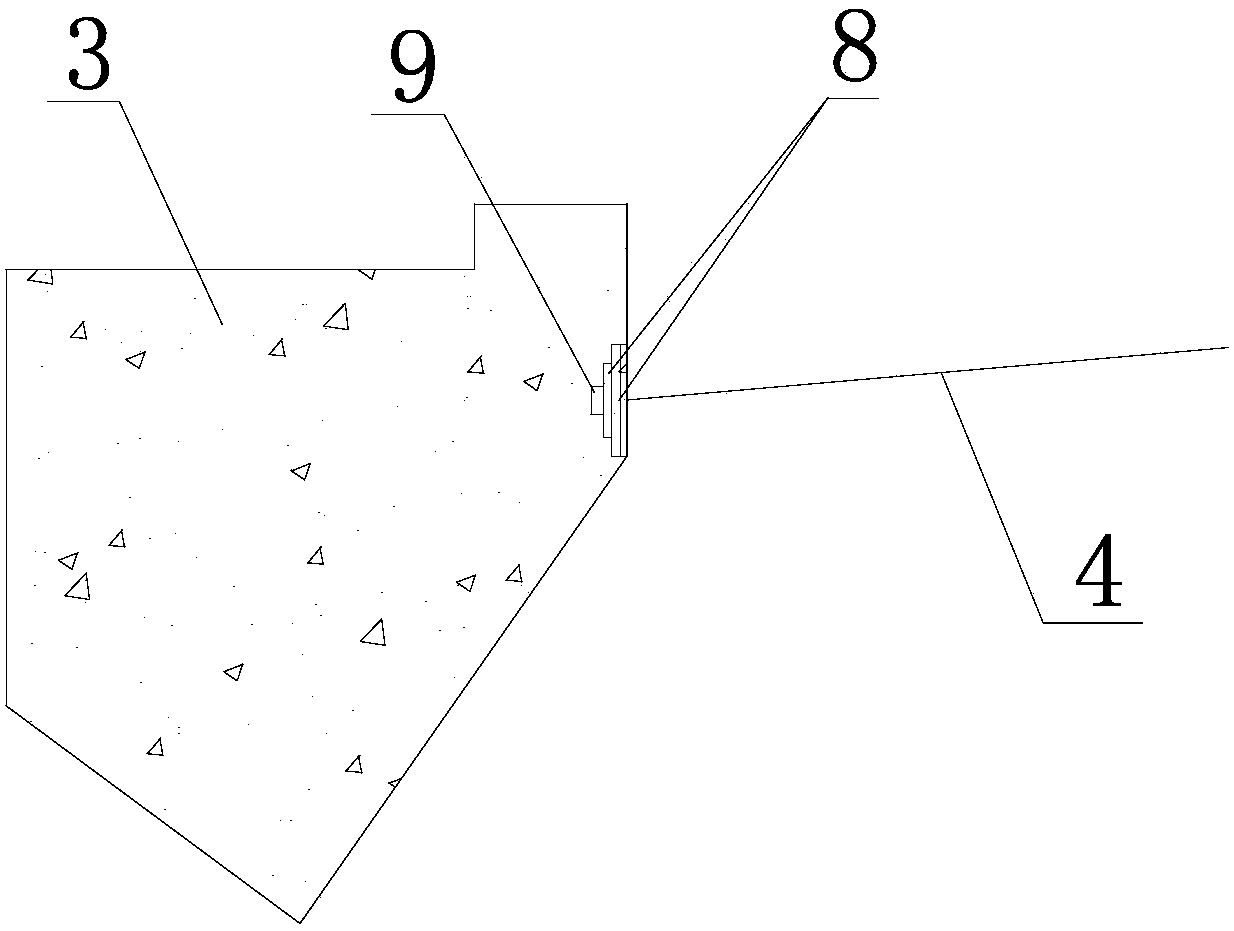

[0021] Such as figure 1 As shown, reference number 1 is an underground factory building, reference number 2 is a side wall of an underground factory building, reference number 3 is a rock wall crane beam structure, and reference number 4 is a prestressed anchor cable.

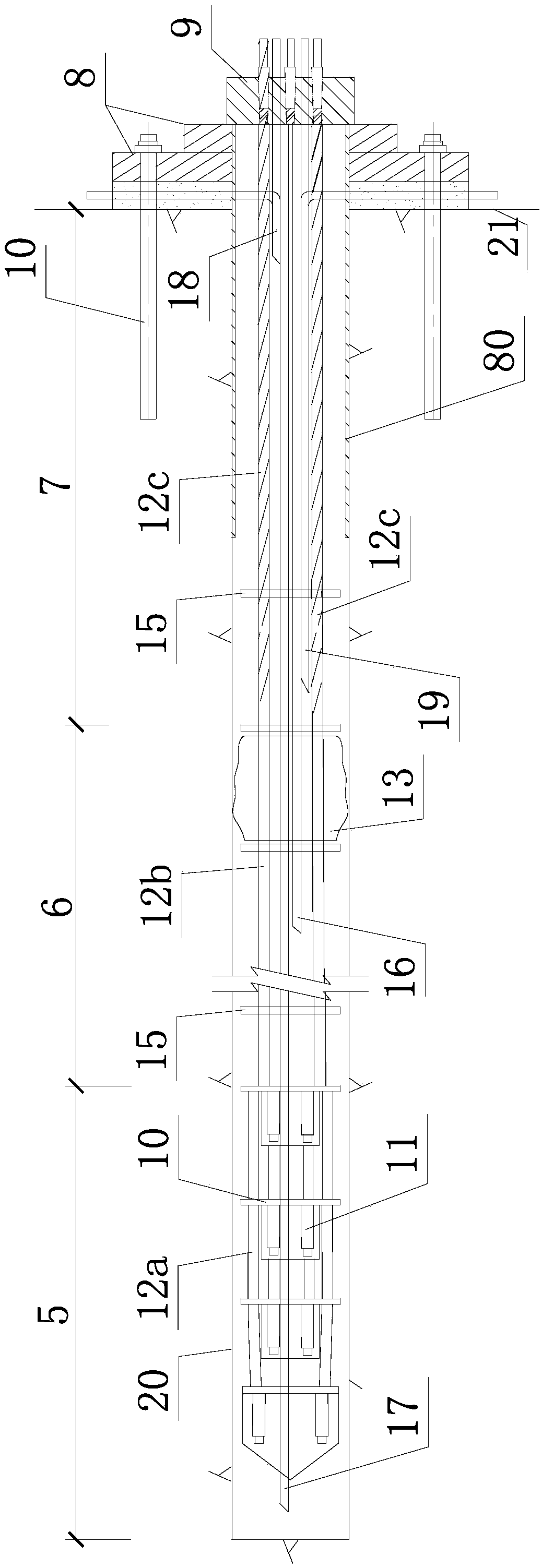

[0022] Such as figure 2 As shown, the main structure of the prestressed anchor cable 4 includes an inner anchor section 5 , a tension section 6 , and an outer anchor section 7 , and the prestressed anchor cable structure also includes a steel backing plate 8 and an anchor 9 .

[0023] The part of the prestressed anchor cable 4 in the inner anchorage section 5 is a steel strand 12a with no adhesive tape PE sleeve. According to the number of steel strands, it is divided into several groups with different lengths and embedded in the extruded sleeve 11 respectively. The extrusion sleeve is connected with the bearing plate 10, and the steel strand load is transferred to the bearing plate through the extrusion slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com