Comprehensive tunnel drainage, precipitation and pressure reduction construction method

A construction method and tunnel technology, which is applied in drainage, earthwork drilling, safety devices, etc., can solve the problems of disrupting the balance of water resources system, abandoning and relocating tunnels, and engineering disasters, so as to improve the physical and mechanical performance indicators of the formation and ensure safety , The effect of protecting the quality and safety of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

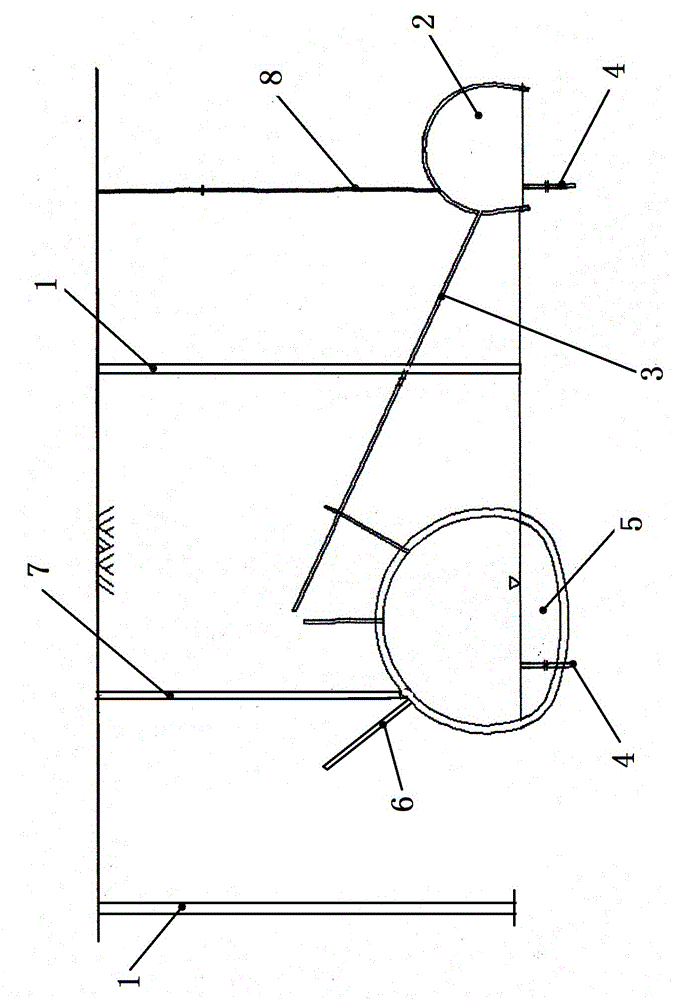

[0020] Refer to attached figure 1 , the ground surface precipitation well 1 is respectively drilled at the place of 8 meters away from the sidelines on both sides of the positive hole 5 on the surface, and the level pilot hole 2 is set near the positive hole on the surface, so as to increase the excavation face while reaching the drainage and dewatering decompression, by Drainage holes 3 are drilled in the flat pilot tunnel towards the surface towards the obliquely upward direction of the main tunnel, tunnel base dewatering wells 4 are drilled at the base of the surface towards the normal tunnel and the base of the flat pilot tunnel, and several slopes are drilled on the surface towards the vault of the main tunnel obliquely forward and upward. To the drain hole 6, the ground surface is set up the vertical drain hole 7 of the positive hole above the vault of the positive hole, and the vertical drain hole 8 of the flat pilot hole is also punched above the vault of the flat pilot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com