Construction technology for soft rock large-deformation tunnel by de-stressing method and matched bracket

A construction technology and large deformation technology, applied in pillars/supports, tunnels, mining equipment, etc., can solve the problems of reduced section, reduced strength of surrounding rock, fracture of bolts and cables, etc., to achieve strong engineering practicability, Long service time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Concrete steps:

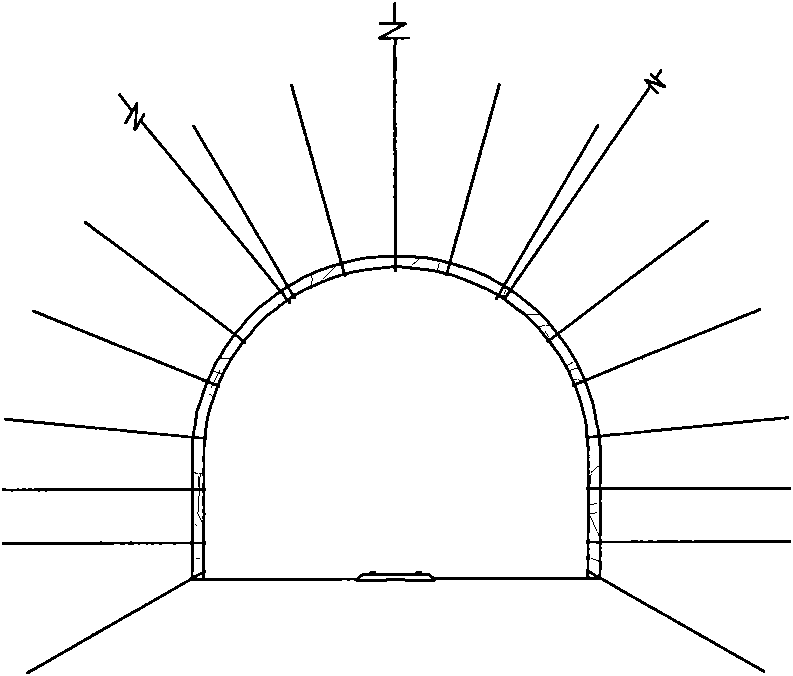

[0033] 1. Excavation construction of shaft and roadway, excavation of shaft and roadway engineering according to the designed section;

[0034] 2. Anchor mesh beam cable and sprayed concrete support construction of the roadway;

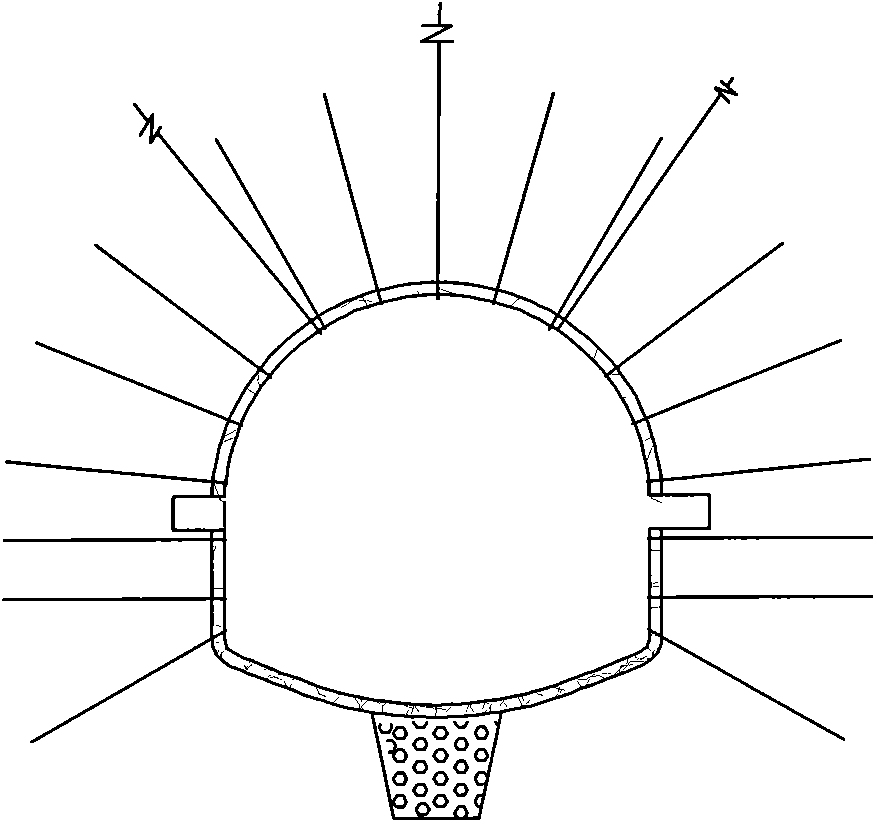

[0035] 3. On the excavated roadway floor, excavate the bottom groove section by section from the excavation working face. The bottom groove is located in the middle of the roadway floor, and a stable area of more than 1.5m is left to keep the rock mass undamaged from the two sides of the roadway; the width of the bottom groove 1.0m, upper width 1.5m, height 1.2m, the pressure relief tank is filled with broken gangue, and the upper surface is poured with concrete and shaped supports to adapt to the shape of the floor, the thickness of the floor is 50-100mm;

[0036] 4. Excavate the roadside pressure relief groove at the side of the roadway, the depth of the pressure relief groove is 600mm, and the height is 400...

Embodiment 2

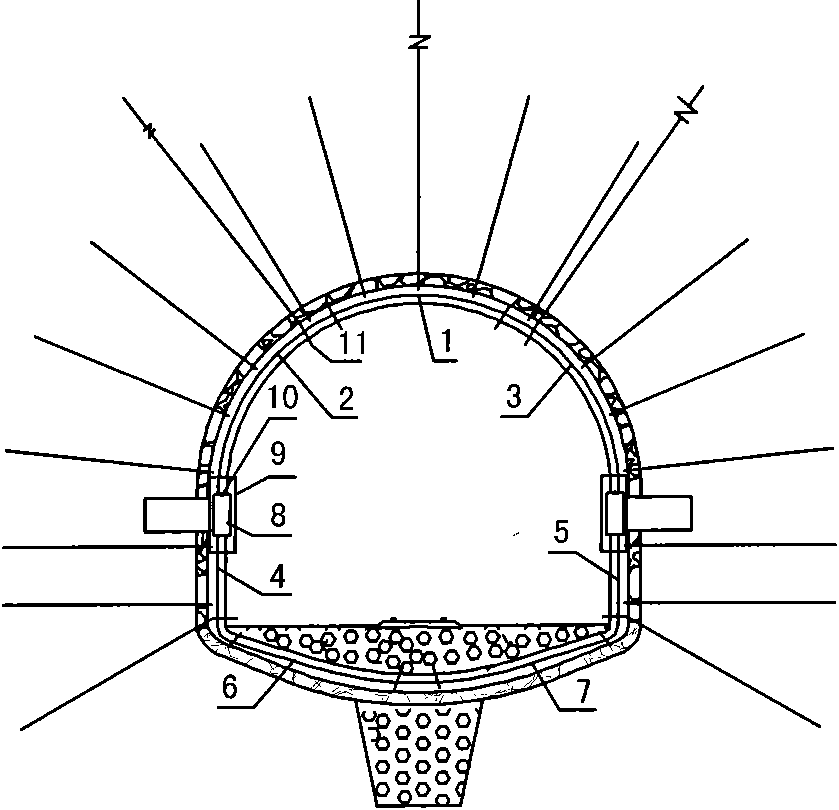

[0041] 1. Pre-process each part of the U-shaped steel bracket according to the cross-section specifications of the shaft, top arch U-shaped steel 1, left arch U-shaped steel 2, right arch U-shaped steel 3, left lane side U-shaped steel 4, right lane side U-shaped steel 5 And left anti-bottom arch U-shaped steel 6, right anti-bottom arch U-shaped steel 7, and cushion block 8, guide groove 9, macromolecule composite material firm pin 10, metal card cable 11 etc. The left arch U-shaped steel 2 and the right arch U-shaped steel 3, the left lane side U-shaped steel 4 and the right lane side U-shaped steel 5 are limitedly connected by the guide groove 9, and the side arch U-shaped steel and the lane side U-shaped steel move in the guide groove. The cushion block 8 is affected by external force on the support, and the shape shrinks gradually.

[0042] 2. According to the designed cross-section, the excavation of the shaft and roadway project is carried out, and the anchor net is supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com