Anchoring slurry material of prestressed anchoring cable of large cross-section tunnel of high-speed rail

A technology of prestressed anchor cables and high-speed railways. It is applied in the installation of anchor rods, mining equipment, earthwork drilling and mining, etc. It can solve the problems that cannot meet the construction requirements and achieve good workability, high early strength and moderate consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take the following materials in terms of mass percentage: sulfoaluminate cement 99.50%, polycarboxylate superplasticizer powder 0.12%, boric acid 0.10%, citric acid 0.15%, air-entraining agent 0.05%, lignin fiber 0.08%, after mixing uniformly , using a water-binder ratio of 0.30 to prepare the grouting material.

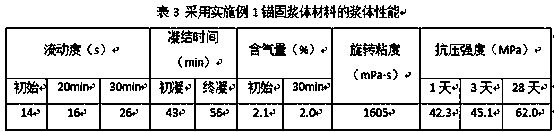

[0035] Use prestressed anchor cable anchor slurry material performance table 3 in embodiment 1:

[0036]

[0037] The slurry in Example 1 remained in a good workable state until 20 minutes after it was discharged from the machine, lost its fluidity in about 35 minutes, and reached initial setting in 43 minutes. The slurry did not bleed and did not sink to the bottom during the whole process. At present, it has been applied in the prestressed anchor cable grouting construction of the large-span transition section of the Badaling Great Wall Station of the Beijing-Zhangjiakou High-speed Railway. During construction, it takes about 10 to 20 minutes to add water...

Embodiment 2

[0039] Take the following materials in terms of mass percentage: sulfoaluminate cement 99.54%, polycarboxylate superplasticizer powder 0.12%, boric acid 0.12%, citric acid 0.15%, air-entraining agent 0.01%, lignin fiber 0.06%, mix well, The prestressed anchor cable grouting material was prepared with a water-binder ratio of 0.32.

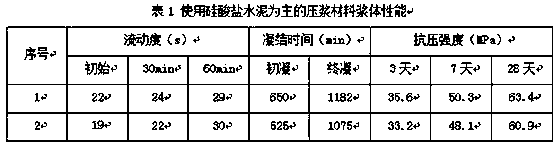

[0040] Use prestressed anchor cable anchor slurry material performance as follows in embodiment 2:

[0041]

[0042] The slurry in Example 2 remained in a good workable state until 20 minutes after leaving the machine, lost fluidity at about 40 minutes, and reached initial setting in 41 minutes. The slurry did not bleed and did not sink to the bottom during the whole process.

Embodiment 3

[0044] Take the following materials in terms of mass percentage: sulfoaluminate cement 99.42%, polycarboxylate superplasticizer powder 0.16%, boric acid 0.18%, citric acid 0.10%, air-entraining agent 0.08%, lignin fiber 0.06%, mix well, The prestressed anchor cable grouting material was prepared with a water-binder ratio of 0.28.

[0045] Use prestressed anchor cable anchor slurry material performance in embodiment 3 as follows:

[0046]

[0047] The slurry in Example 3 remained in a good workable state until 20 minutes after leaving the machine, lost fluidity at about 34 minutes, and reached initial setting in 35 minutes. The slurry had no bleeding or sinking during the whole process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com