Split-spoon change-over switch in on-load tap-changer

A transfer switch and on-load tapping technology, which is applied in the field of electromechanical manufacturing, can solve the problems of complex structure and low assembly efficiency of the high-low push-post transfer switch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In view of the existing technical defects, the purpose of the patent of this invention is to provide a split transfer switch. During the operation of the transfer switch, due to the large distance between the static contacts, the static contact of the split transfer switch The head is not easy to be broken down, so that the reliability of the switch can be improved. Moreover, the invention has a simple and compact structure and is easy to assemble.

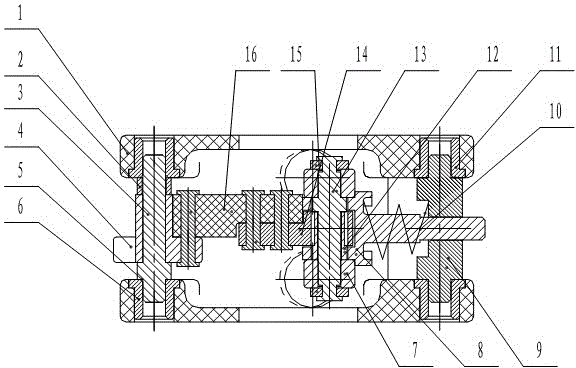

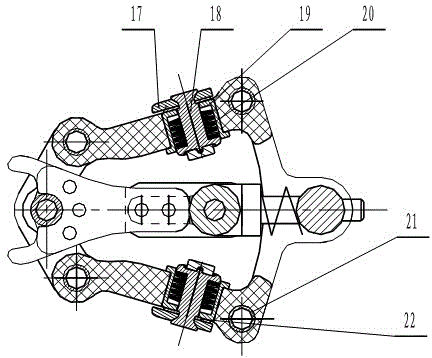

[0022] Such as figure 1 , figure 2 As shown, the split change-over switch in the on-load tap-changer, the change-over switch includes:

[0023] Box 1, the load-bearing installation part of the entire split transfer switch; the second bushing 19 is installed on the box 1; the disc spring 20 is installed between the static contact 18 and the second bushing 19; the third bushing 21 is located in the box 1 Cavity; bushing one 2, mounted on shaft one 3, to prevent shifting fork 4 from sliding up and down; shifting fork 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com