Free-open-close turnover shaft-less film winding device

A technology of a rewinding device and a turning device, which is applied in the directions of winding strips, thin material processing, transportation and packaging, can solve the problem of needing to extract the reeling shaft, and achieves the goal of reducing labor intensity, facilitating loading and unloading, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

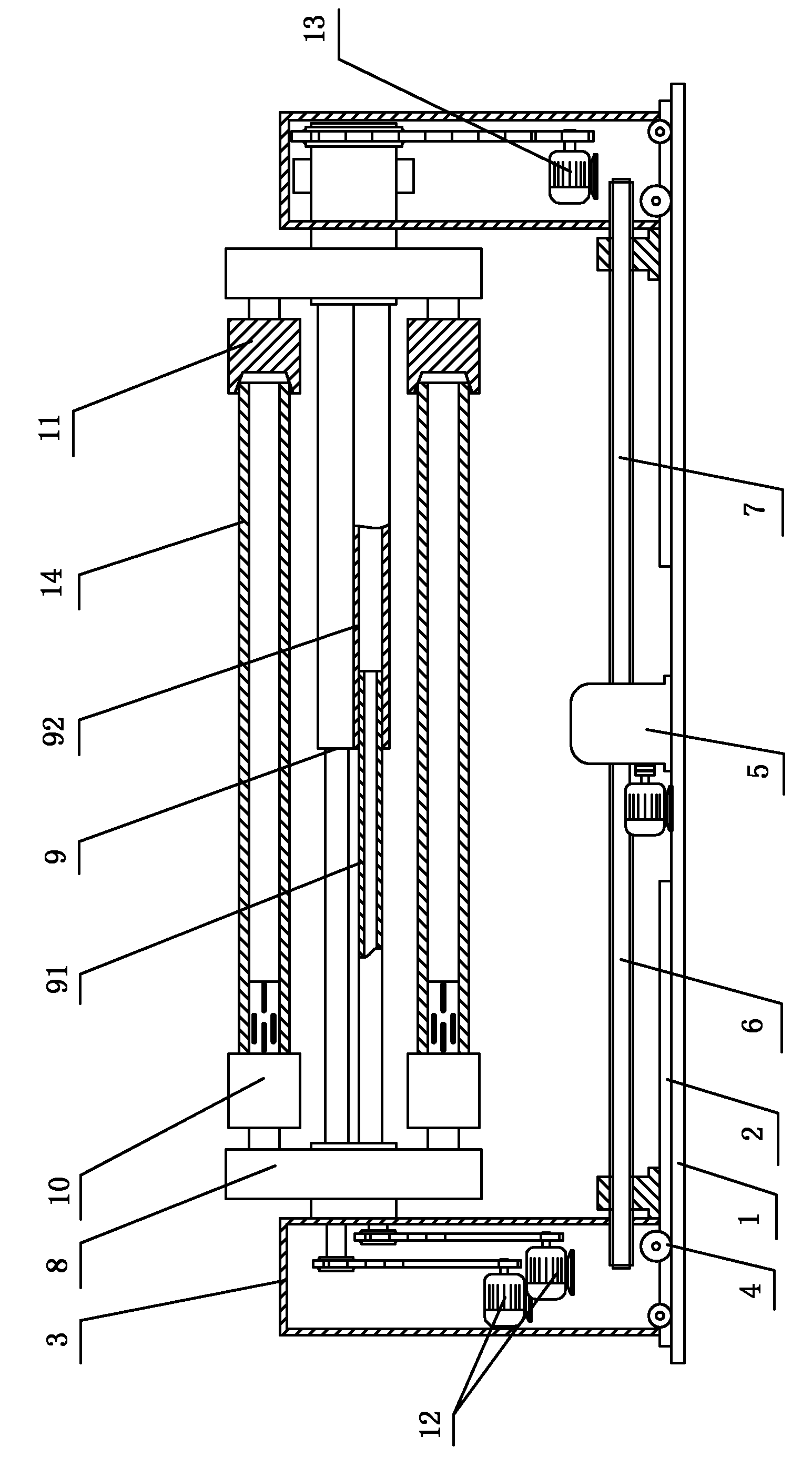

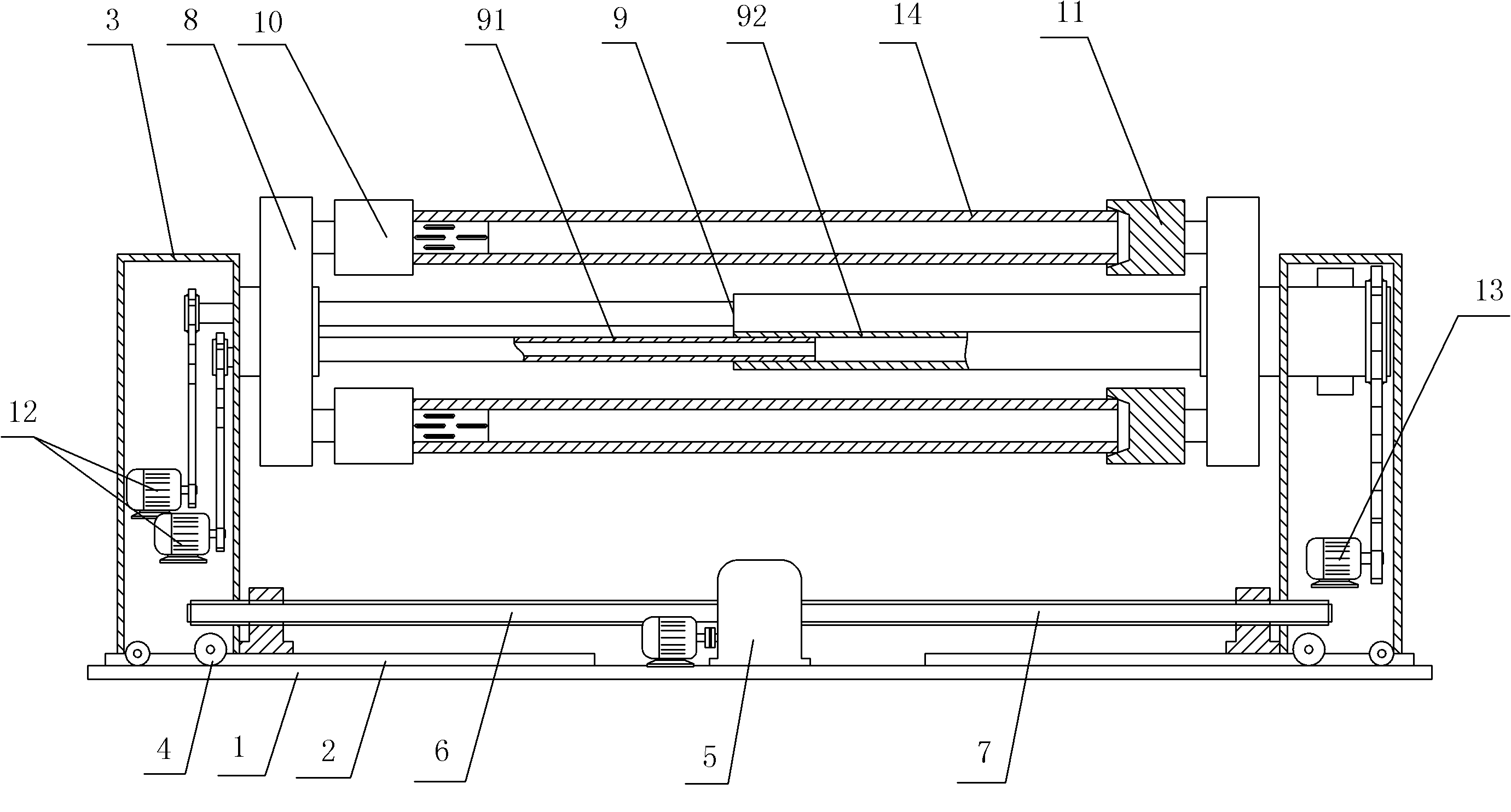

[0008] Such as figure 1 As shown, the freely opening and closing reversible film shaftless rewinding device includes a rewinding support, a reversing device fixed on the rewinding support and a transmission device with a control panel. Rewinding motor 12 and the turning motor 13 of control overturning device, described rolling support comprises base 1, guide rail 2, sliding support 3 and sliding connection device, the two ends of base 1 are respectively fixed with a guide rail 2, and sliding support 3 installs Above the guide rail 2, the bottom is provided with a pulley 4 that matches the guide rail 2. The sliding connection device includes a worm gear reducer 5 and lead screws fixed on both sides of the output shaft of the worm reducer 5. The lead screw is located on the left side of the worm reducer 5. It is a left-handed screw 6, and what is located on the right side of the worm gear reducer 5 is a right-handed screw 7. The other ends of the left-handed screw 6 and the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com