All-round manipulator special for tunnels

A manipulator and all-round technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as long installation time of a single arch, influence on tunnel construction progress, and high work intensity of workers, so as to save construction time, improve safety, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

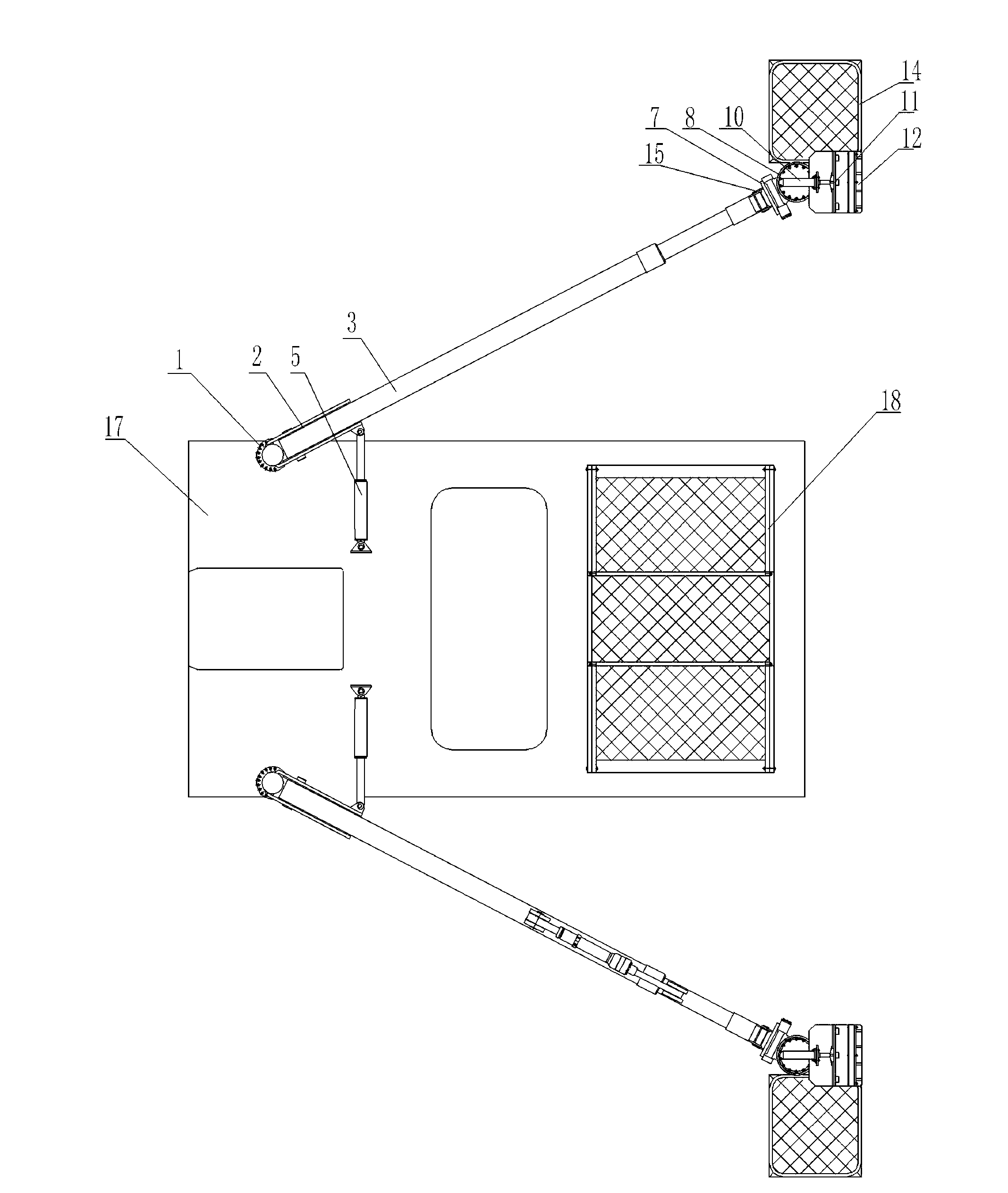

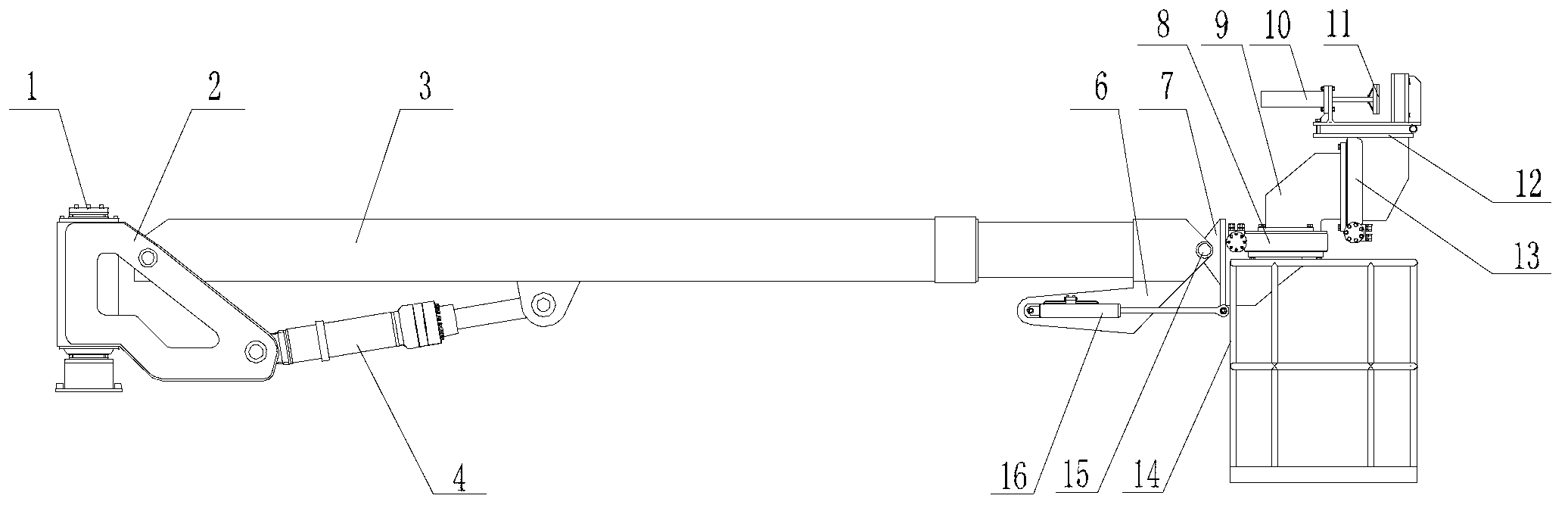

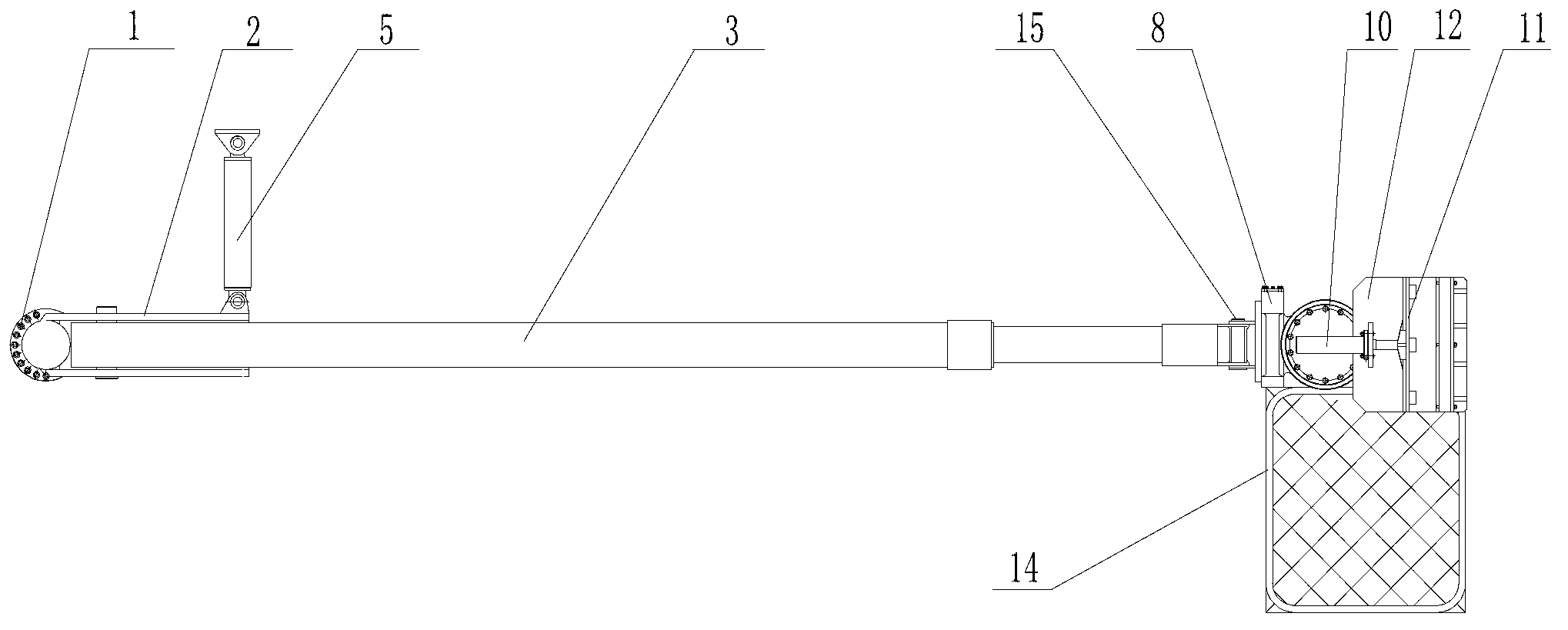

[0011] Such as figure 1 , figure 2 As shown, an all-round manipulator for tunnels includes a telescopic arm 3, one end of the telescopic arm 3 is mounted on the telescopic arm rotating bracket 2, the telescopic arm rotating bracket 2 is equipped with a rotating base 1, and the telescopic arm rotating bracket 2 is equipped with a telescopic arm Rotating cylinder 5; one end of the luffing cylinder 4 is mounted on the telescopic arm rotating bracket 2, and the other end is mounted on the telescopic arm 3. A manipulator is mounted on the front end of the telescopic arm 3. The manipulator includes a leveling mounted on the front end of the telescopic arm 3 The cylinder mounting seat 6, the leveling rotating seat 7 are connected to the top end of the telescopic arm 3 through the leveling shaft 15 and the automatic leveling cylinder 16 is connected to the leveling cylinder mounting seat 6 at one end, and the other end is connected to the leveling rotating seat 7 ; The leveling and rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com