Full-automatic assembling device of puncture connector

A technology for assembly equipment and connectors, which is applied in the field of fully automatic assembly equipment, can solve the problems of difficulty in ensuring assembly accuracy and product quality, slow assembly speed of manual clamping parts, and inability to meet electronic production, so as to improve production efficiency and improve The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

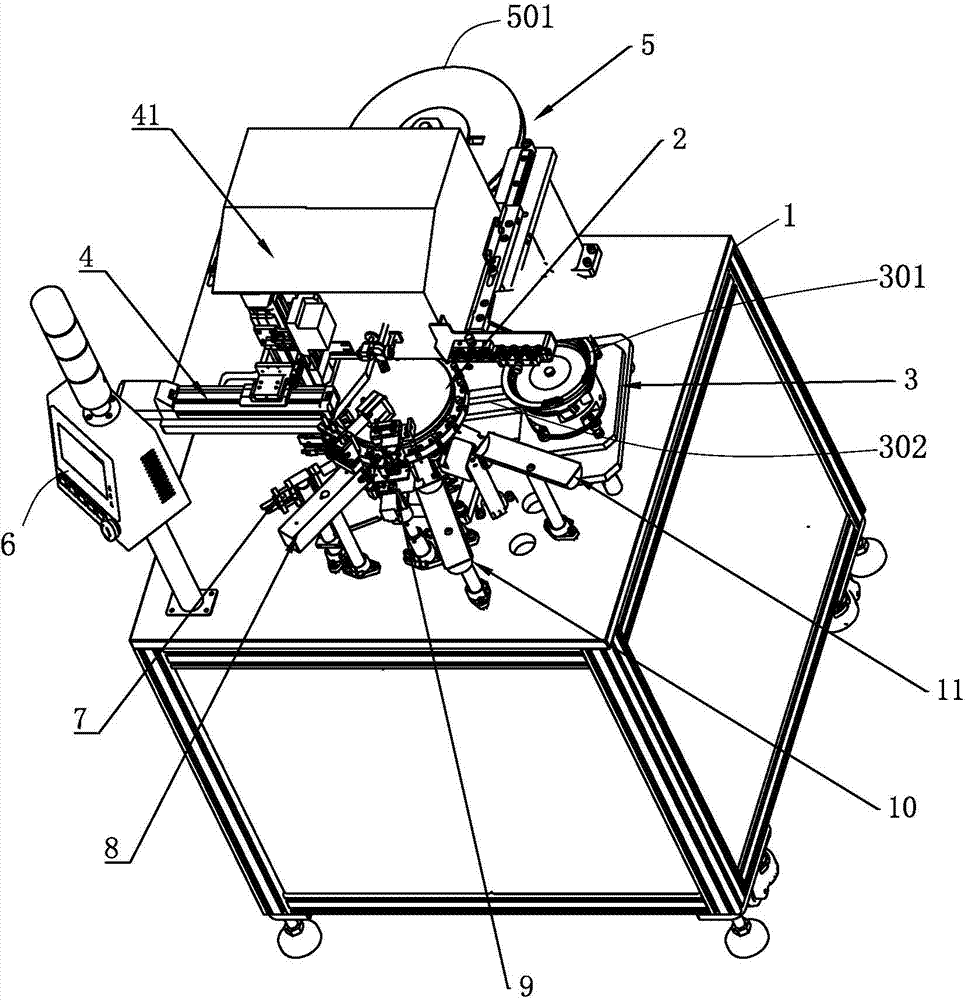

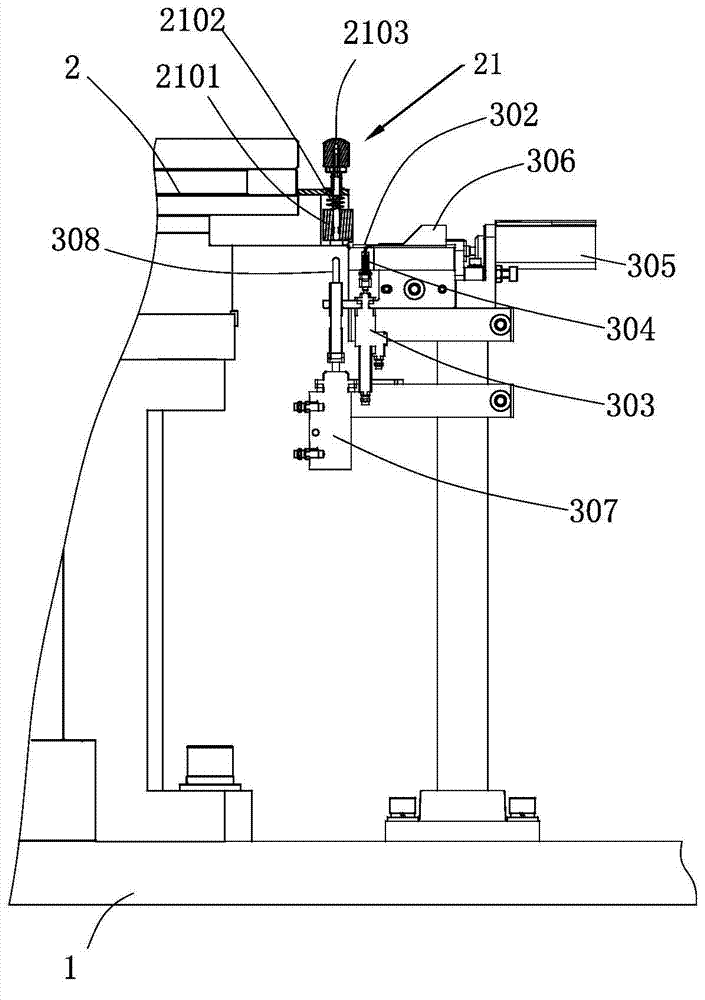

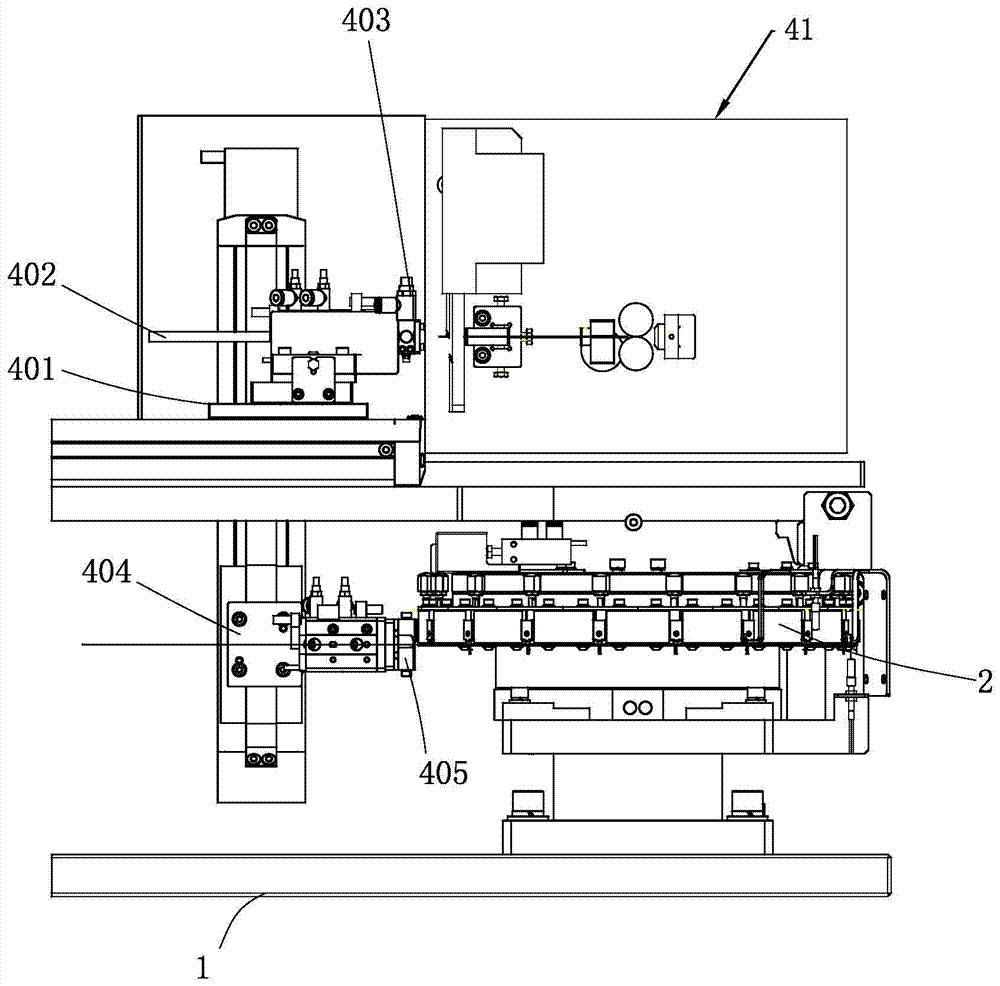

[0028] Such as figure 1 and figure 2 Commonly shown, a fully automatic assembly equipment for piercing connectors mainly includes a frame 1; a disc-shaped assembly workbench 2 driven by a first power device, the first power device is preferably a servo motor or Stepper motor (not shown in the figure), the assembly table 2 is installed on the frame 1 through bearing rotation, and the ring array on the assembly table 2 is provided with a number of slots for the plastic shell of the connector, and the slots work along the assembly line. The radial extension of the table 2, the top of the slot is provided with a pressing device 21 for pressing the plastic case, the pressing device 21 includes a pressing block 2101 arranged in the slot, and the pressing block 2101 is connected to a pressure block 2101 Compress the elastic element of the plastic case, the elastic element usually chooses the compression spring 2102, in order to adjust the preload of the compression spring 2102, usu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com