Strapping machine

A binding machine and binding wire technology, applied in the field of mechanical packaging, can solve the problems of difficult operation, high labor costs, high cost, etc., and achieve the effect of convenient binding of objects, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

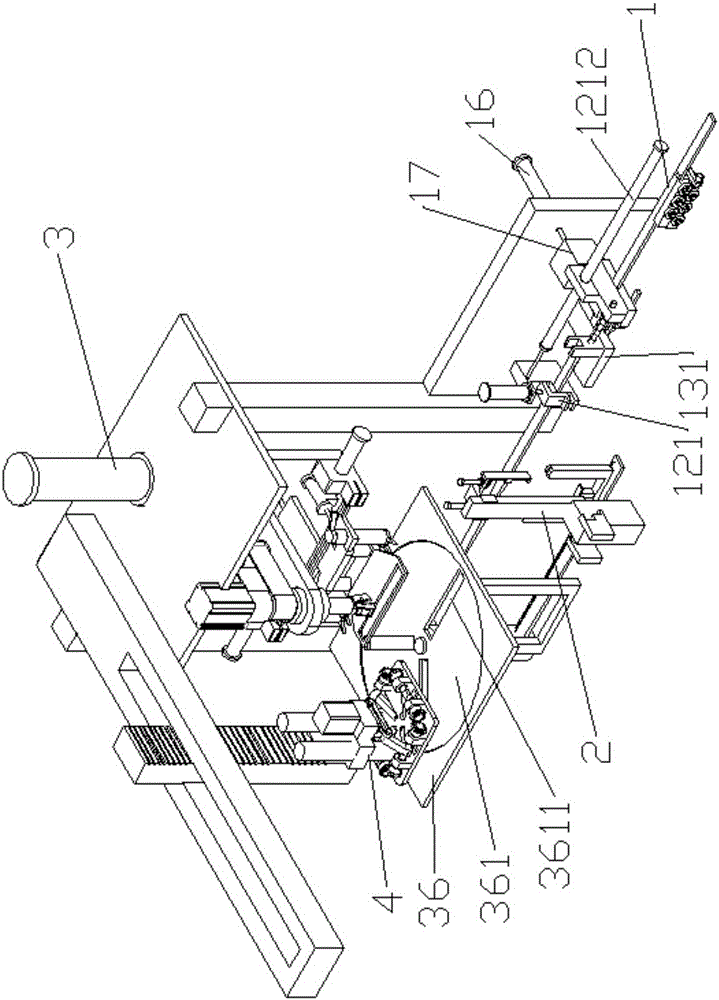

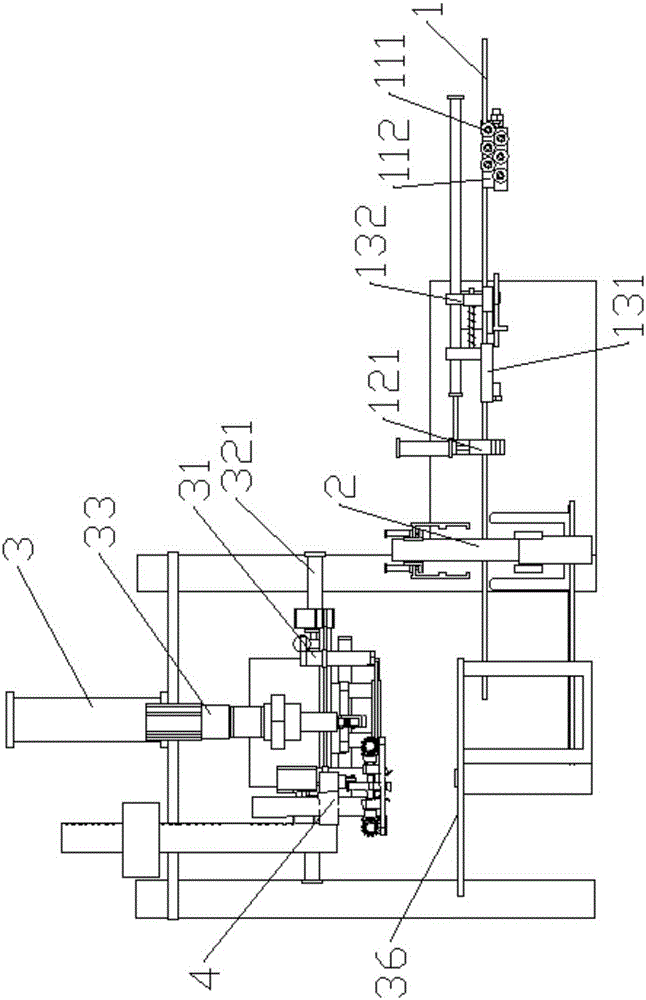

[0064] A strapping machine such as figure 1 , figure 2 , image 3 As shown, it includes a placement table 36 for placing objects to be bundled, a wire feeder 1 for sending the binding wire to the object to be bundled below, and a binding device 3 for binding the objects to be bundled with the binding wire. The device 3 is located above the placement table 36, and the binding device 3 includes two binding clamps 31, a binding lateral movement mechanism 321 for controlling the lateral movement of the two binding clamps 31, a rotating clamp 33 and The rotary mechanism 34 that controls the rotation of the rotary thread gripper 33 , and the two binding thread grippers 31 are respectively located on both sides of the rotary thread gripper 33 .

[0065] In the prior art, metal wires are often used as the binding wires, and the wire feeding device 1 sends the binding wires to the bottom of the strapped objects, and the binding means of the binding device 3 can be the following two ...

Embodiment 2

[0069] On the basis of embodiment one, described embodiment two has been further improved, as figure 1 , figure 2 , image 3 As shown, a U-shaped wire forming device 2 is provided between the binding device 3 and the wire feeding device 1, such as Figure 10 , Figure 11 As shown, the U-shaped wire forming device 2 includes a U-shaped frame 21, a U-shaped frame vertical moving mechanism for vertically moving the U-shaped frame 21, a wire feeding mechanism for sending the wire to the top of the U-shaped frame 21, At least one wire crimping device for clamping and arranged above the U-shaped frame 21 and a wire crimping lifting mechanism 23 for controlling the lifting of the wire crimping device.

[0070] The U-shaped frame 21, as the name implies, generally includes two side bars and a bottom connector for connecting the two side bars. Of course, the U-shaped frame 21 can also be a V-shaped wire forming frame, as long as the two side bars The bottom end can be tilted inwar...

Embodiment 3

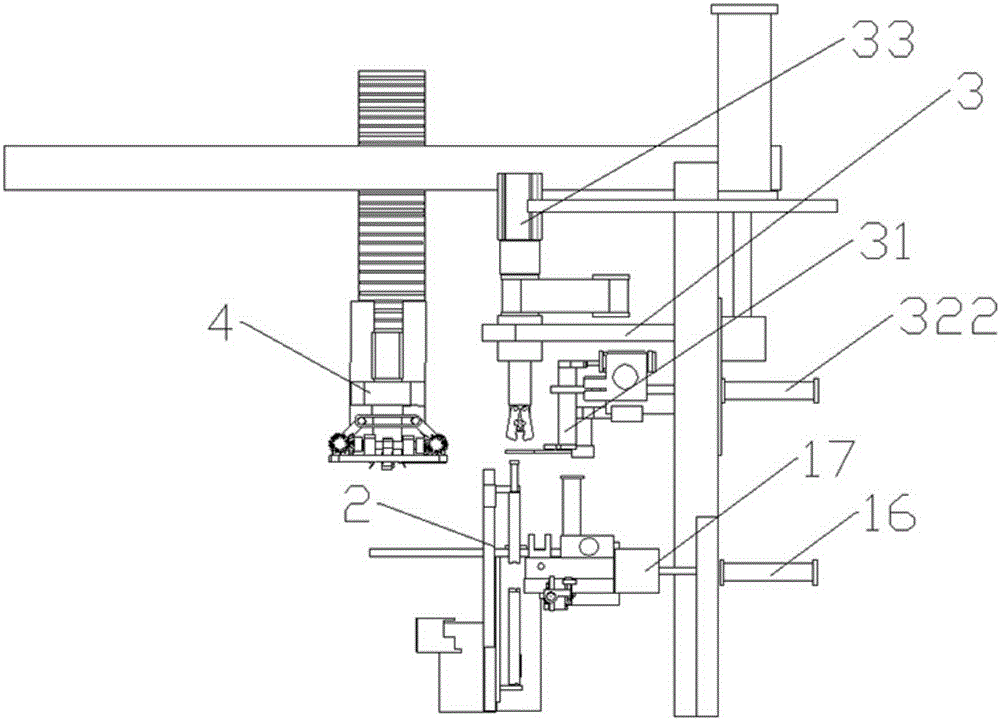

[0075] On the basis of embodiment two, described embodiment three has been further improved, as Image 6 As shown, the binding device 3 also includes a binding longitudinal movement mechanism 322 for controlling the longitudinal movement of the two binding clamps 31 .

[0076] In the U-shaped frame 21, the two ends of the U-shaped wire are higher than the two ends of the U-shaped frame 21, so that the binding clamp 31 can grab the ends of the U-shaped wire. When the U-shaped frame 21 sends the two ends of the U-shaped wire to the top of the object to be bound, if the binding clamp 31 is also just above the U-shaped frame 21, the vertical moving device of the U-shaped frame 21 will During the process of the U-shaped frame 21 sending the thread ends at both ends of the U-shaped wire upward, if the ends of the thread ends do not pass through the clamping range of the binding clamp 31 , the clamping failure will result.

[0077] The binding longitudinal moving mechanism 322 now m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com