PPR pipe hot melting machine

A hot-melting machine and pipe technology, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of low manual connection efficiency, difficult to guarantee connection quality, affecting work progress, etc., so as to improve the welding efficiency and ensure the welding quality. , the effect of precise docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

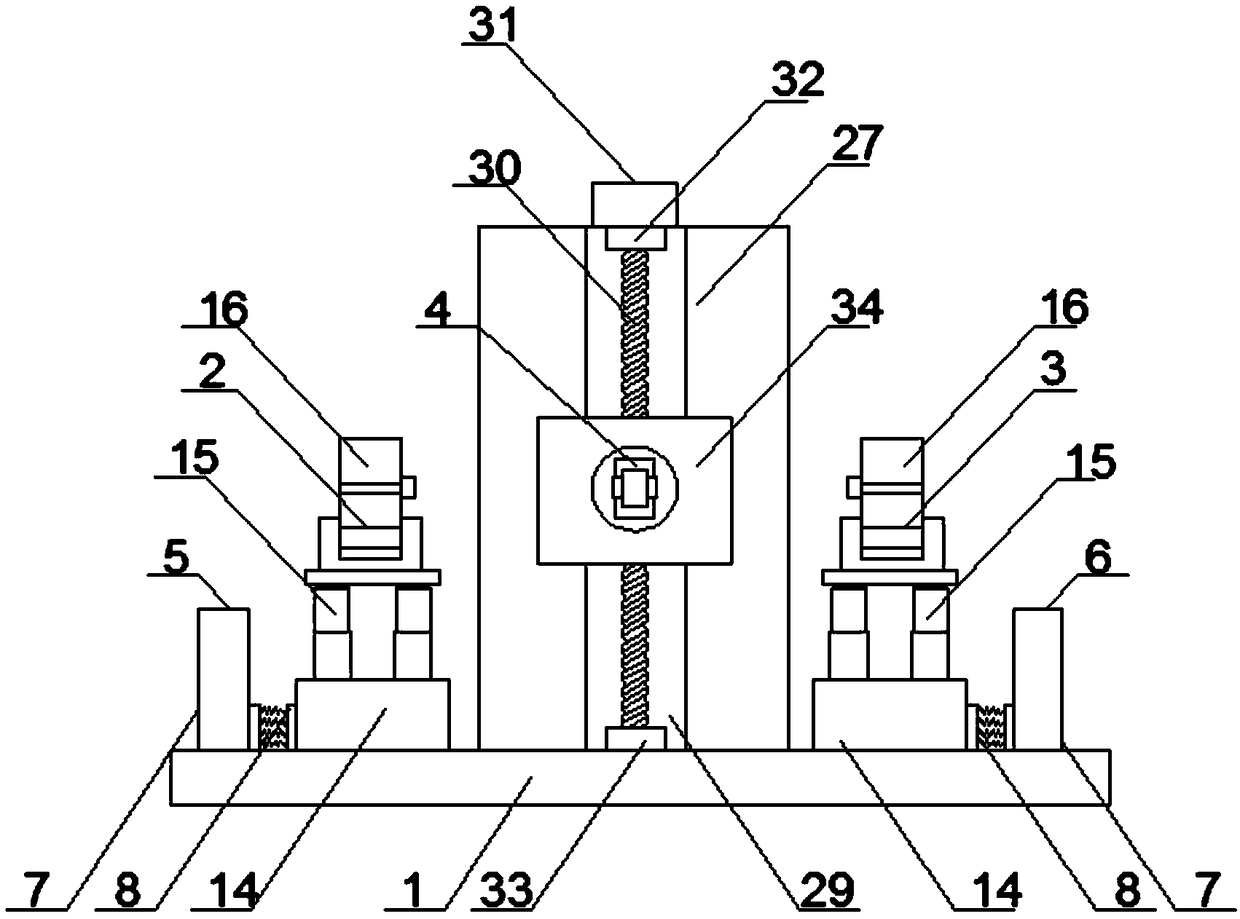

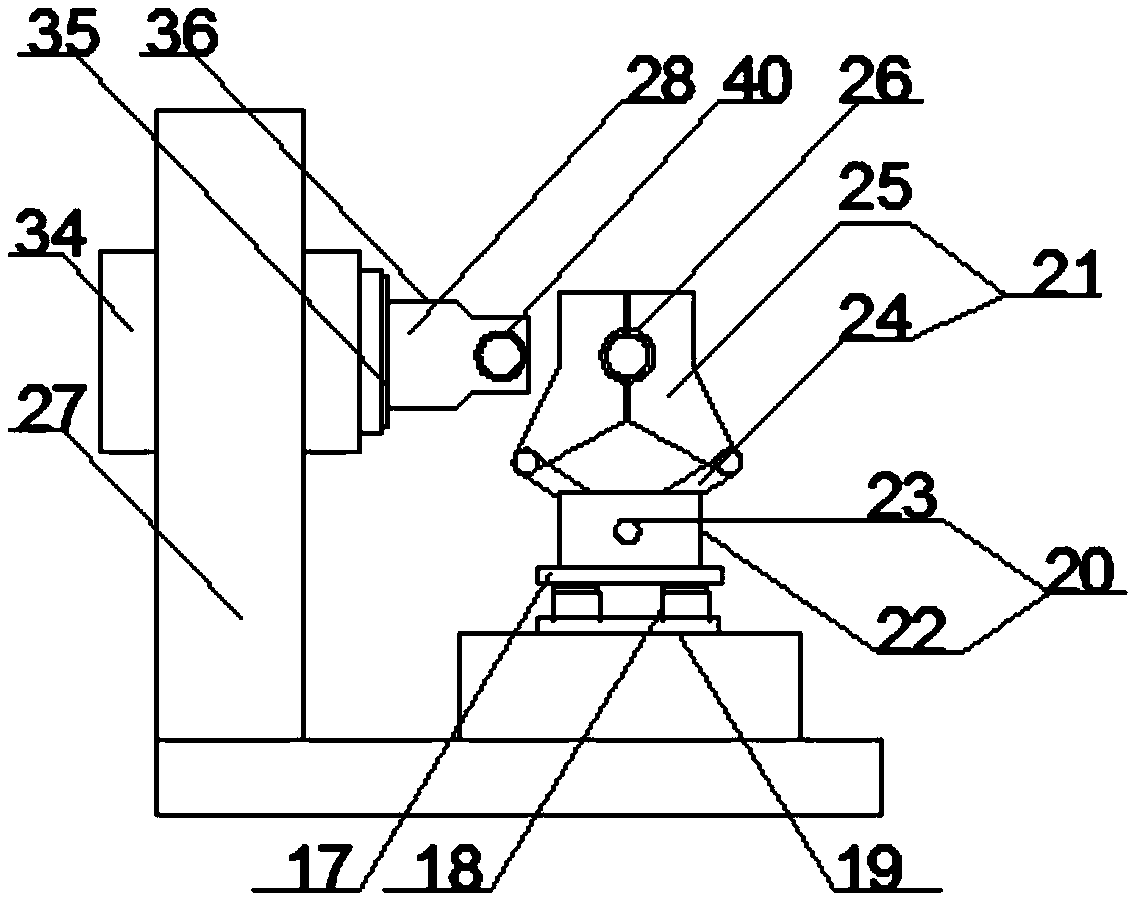

[0024] Such as figure 1 and figure 2 As shown, a PPR pipe hot-melt machine includes a platform 1, a first clamping mechanism 2, a second clamping mechanism 3, and a hot-melt mechanism 4; the first clamping mechanism 2 and the second clamping mechanism 3 are arranged on the platform 1 and located between the first limit mechanism 5 and the second limit mechanism 6, the two are oppositely arranged, wherein the first clamping mechanism 2 is close to the first limit mechanism 5, and the second clamping mechanism 3 is close to the second limit mechanism The position mechanism 6; the hot-melt mechanism 4 is arranged on the platform 1 and located between the first clamping mechanism 2 and the second clamping mechanism 3 .

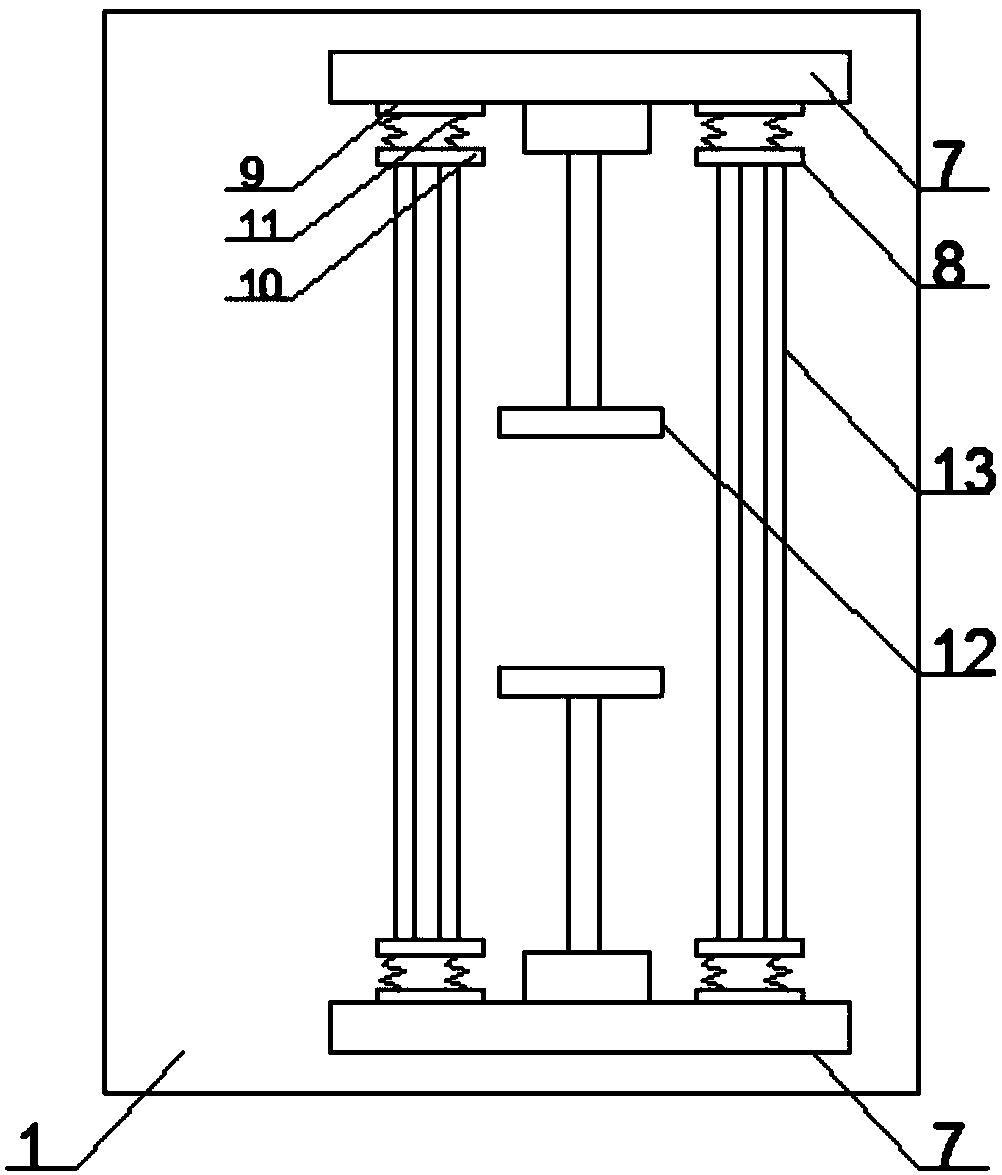

[0025] Such as image 3 As shown, the platform 1 is provided with a first limiting mechanism 5 and a second limiting mechanism 6, the first limiting mechanism 5 and the second limiting mechanism 6 all include a limiting plate 7 and a buffer pad 8, and the buffe...

Embodiment 2

[0030] Such as figure 1 and Figure 5 As shown, a PPR pipe hot-melt machine includes a platform 1, a first clamping mechanism 2, a second clamping mechanism 3, and a hot-melt mechanism 4; the first clamping mechanism 2 and the second clamping mechanism 3 are arranged on the platform 1 and located between the first limit mechanism 5 and the second limit mechanism 6, the two are oppositely arranged, wherein the first clamping mechanism 2 is close to the first limit mechanism 5, and the second clamping mechanism 3 is close to the second limit mechanism The position mechanism 6; the hot-melt mechanism 4 is arranged on the platform 1 and located between the first clamping mechanism 2 and the second clamping mechanism 3 .

[0031] Such as image 3 As shown, the platform 1 is provided with a first limiting mechanism 5 and a second limiting mechanism 6, the first limiting mechanism 5 and the second limiting mechanism 6 all include a limiting plate 7 and a buffer pad 8, and the buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com