Rail shifter and long rail carrier vehicle

A technology for pulling steel rails and moving devices, which is applied in the directions of transportation of passenger cars, transportation and packaging, and rails, can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing personal safety, reducing labor intensity and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

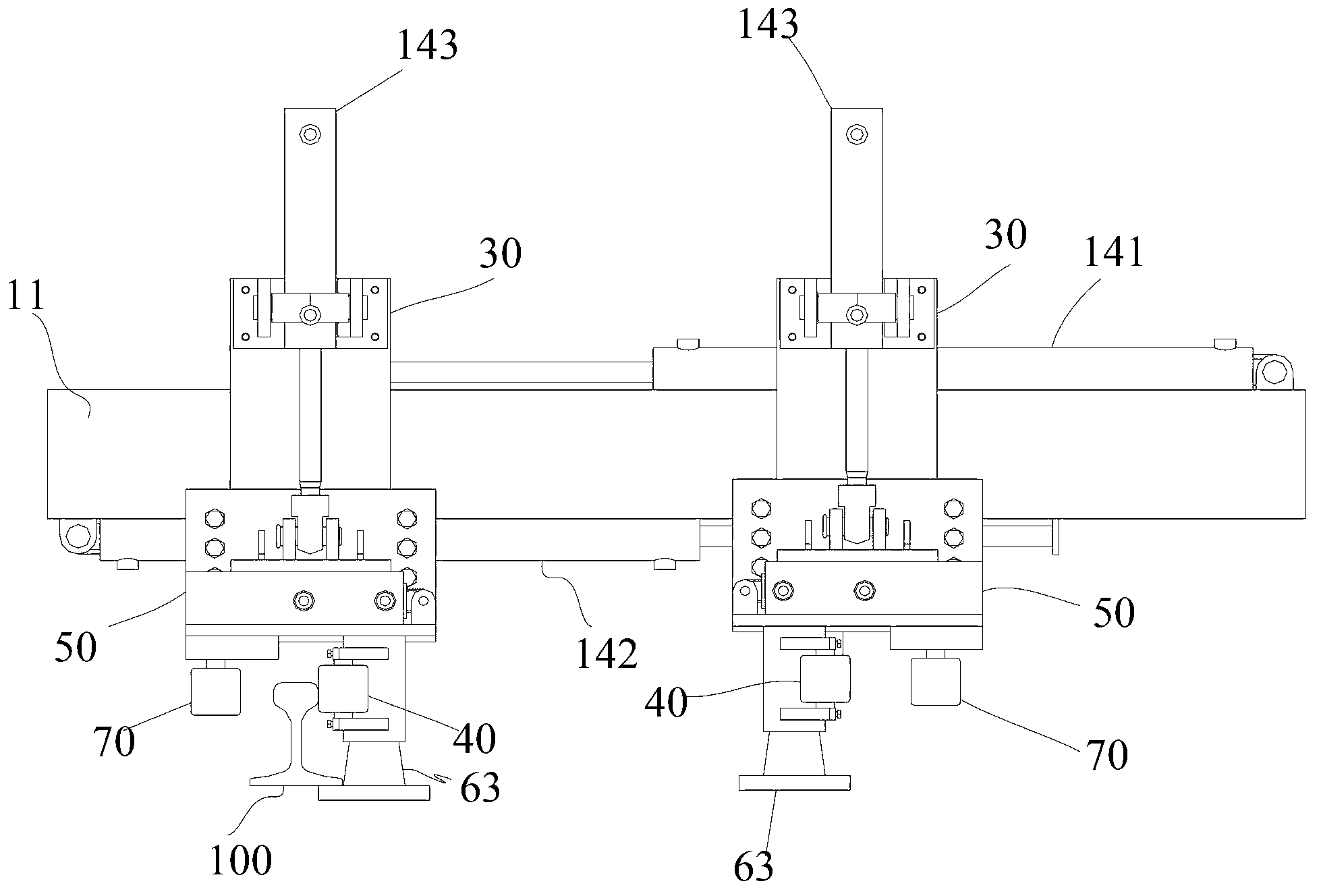

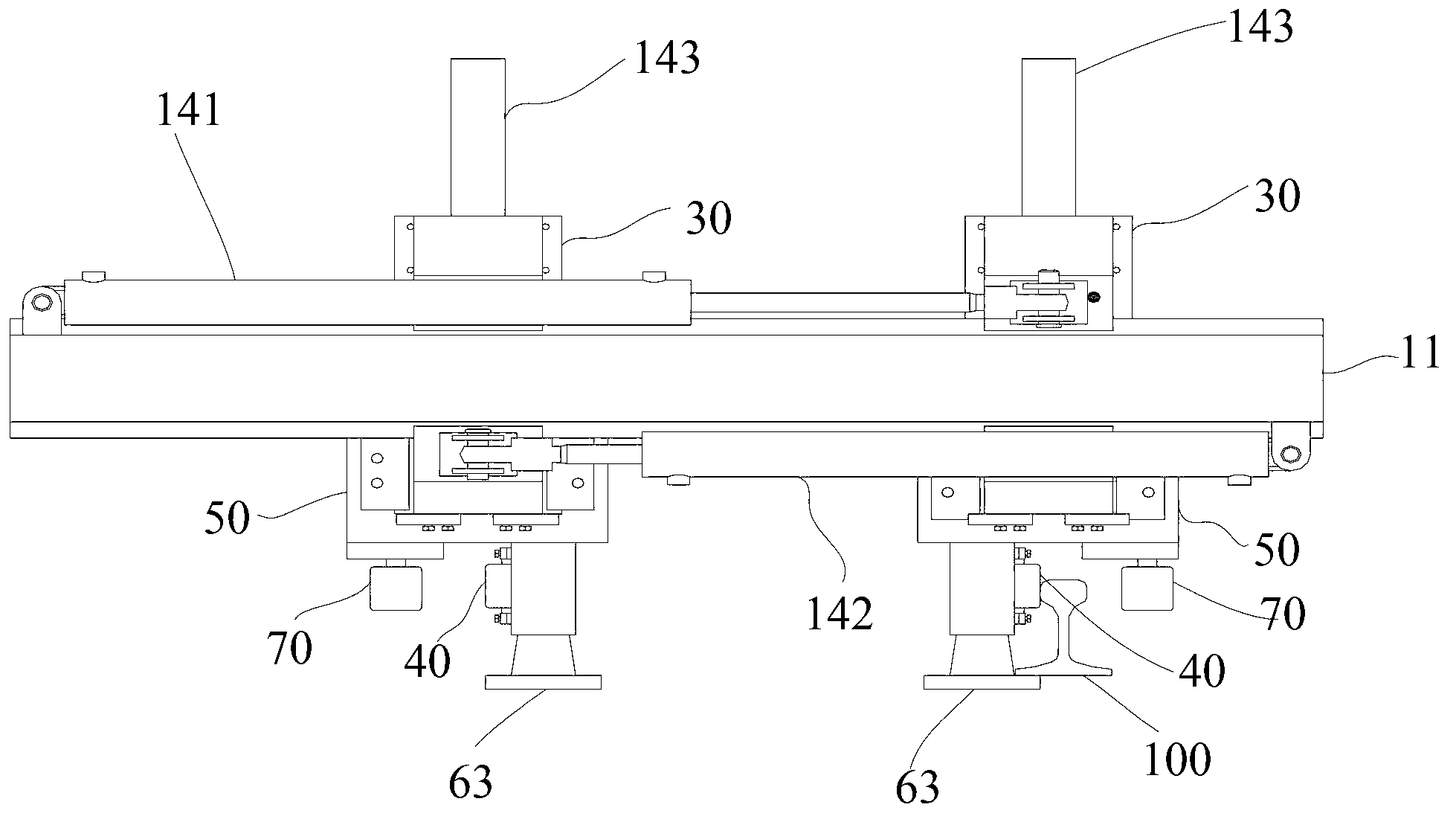

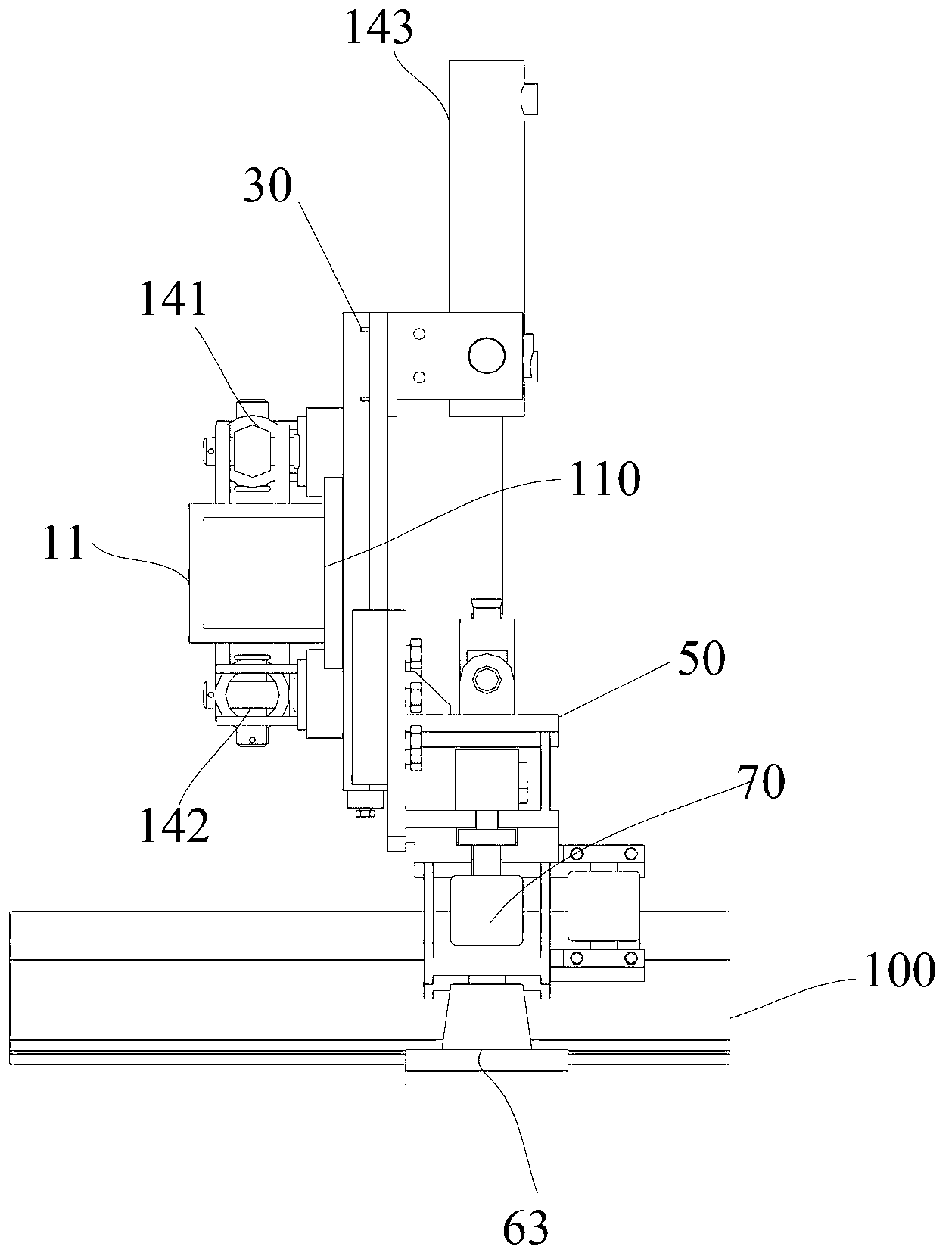

[0019] Such as Figure 1-11 As shown, the present invention provides a rail shifting device. The device includes a lateral movement device, at least one vertical movement device and at least one claw device. The lateral movement device includes a lateral support beam 11 and at least one fixed to the lateral support beam 11 The vertical telescopic arm; the vertical movement device includes a sliding seat 30 that can move on the lateral support beam 11 and a vertical telescopic arm 143 fixed on the sliding seat 30; the jaw device includes a vertical telescopic arm fixed The mounting seat 50 at the bottom of 143, the supporting roller component 63 used to hold the bottom of the rail 100, the fixed claw 40 and the movable claw 70 that can move laterally relative to the fixed claw, the supporting roller component 63 and the fixed claw 40 are fixed on On the mounting seat 50, the fixed claws 40 and the movable claws 70 are arranged oppositely and are located above the supporting wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com