A steam pressurized sand-water separation and filtration device

A filter device and sand-water separation technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of long time-consuming, inability, and more energy consumption of filtration separation, so as to improve the efficiency of single collection, Enhance fluidity and quick pumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

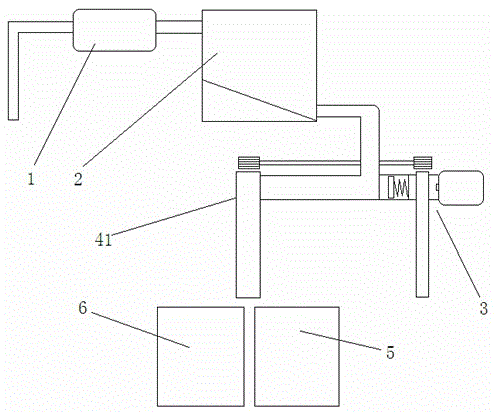

[0039] A steam pressurized sand-water separation and filtration device, comprising a water pump 1, a reservoir 2 and a sediment filter device connected in series by water pipes in sequence, the water pipe connecting the reservoir 2 and the sediment filter device is provided with a steam push device 3;

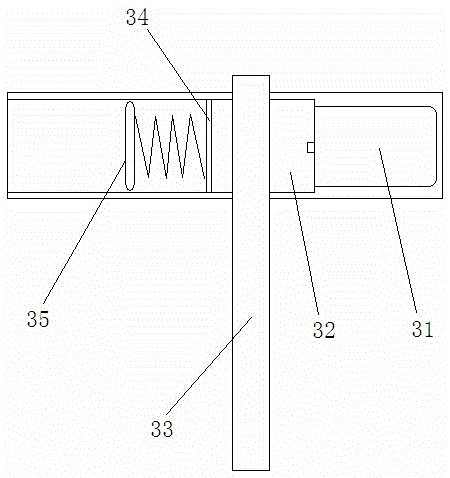

[0040] The steam propulsion device 3 includes a heating chamber 31, a compression cylinder 32, a rotating valve 33, a mesh layer 34, and a pushing piston 35 arranged in the direction of the water pipe in sequence, and the heating chamber 31 has an exhaust port to the compression cylinder 32. The rotary valve 33 is an annular structure that rotates around its center of circle. A part of the annular surface is in the cross-section of the compression cylinder 32. The annular surface is provided with a through hole for guiding the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com