Blockage-resistant pervious concrete as well as preparation method and application thereof

A permeable concrete and anti-blocking technology, applied in the field of building materials, can solve the problems of reduced pavement permeability, economic waste, large porosity, etc., and achieve the effect of improving compressive strength and freeze-thaw resistance, and avoiding strength reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

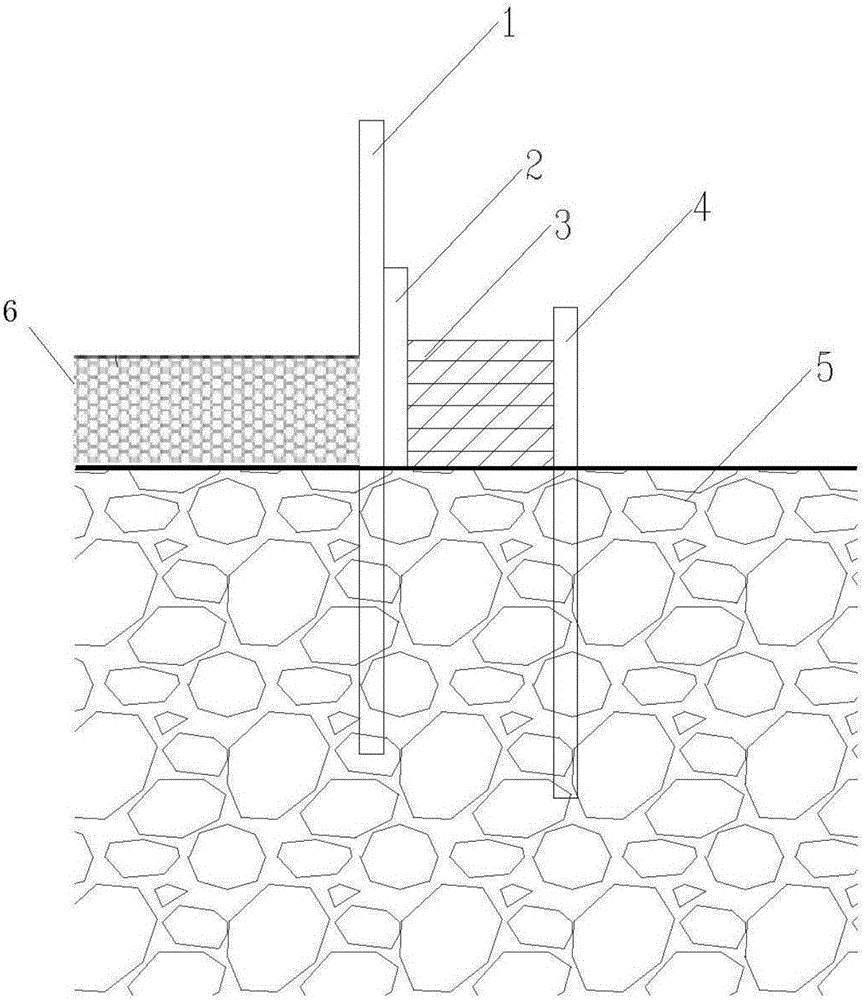

Image

Examples

preparation example Construction

[0039] The present invention provides a method for preparing the anti-blocking permeable concrete described in the above technical solution, comprising the following steps:

[0040] (1) mixing water reducer, redispersible latex powder and water to obtain a mixed solution;

[0041] (2) Portland cement, crushed stone, quartz sand, fly ash, slag micropowder and modified polypropylene fiber are mixed to obtain a mixed material;

[0042] (3) Mixing the mixed solution obtained in the step (1) and the mixed material obtained in the step (2) to obtain an anti-blocking permeable concrete.

[0043] There is no chronological order restriction between said step (1) and step (2).

[0044] The invention mixes the water reducing agent, the redispersible latex powder and water to obtain a mixed solution. The present invention has no special requirements on the mixing method, and a mixing method well known to those skilled in the art can be used. In the present invention, the mixing process...

Embodiment 1

[0057] 22 parts of Portland cement, 38 parts of continuously graded crushed stone with a particle size of 5-16mm, the mud content of the crushed stone is 0.8wt%, 28 parts of quartz sand with a particle size of 0.55mm, (I) grade pulverized coal 3 parts of ash, the fineness of fly ash is 9%, the water demand ratio of fly ash is not more than 95%, the 7-day activity index is not less than 75% and the 28-day activity index is not less than 95% slag fine powder5 parts, the specific surface area of slag fine powder is 450m 2 / kg, the particle size of slag powder is 15 μm, 0.40 parts of modified polypropylene fiber, 2 parts of Wacker5044N with a particle size of 10 μm, 1.3 parts of PCA—I carboxylic acid high-performance water reducer, and the solid content of the water reducer is 30wt%. , the water reduction rate is 40%, and water is added according to the water-binder ratio of 0.30.

[0058] Modified polypropylene fiber is obtained by modifying polypropylene 6820 with 7008p hydro...

Embodiment 2

[0062] 30 parts of Portland cement, 35 parts of continuously graded crushed stone with a particle size of 5-16mm, the mud content of the crushed stone is 0.5wt%, 25 parts of quartz sand with a particle size of 0.55mm, (I) grade pulverized coal 2 parts of ash, the fineness of fly ash is 10%, the water demand ratio of fly ash is not more than 95%, the 7-day activity index is not less than 75% and the 28-day activity index is not less than 95% 3 parts of slag micropowder , the particle size of slag powder is 20μm, and the specific surface area of slag powder is 450m 2 / kg, 0.48 parts of modified polypropylene fiber, 2.2 parts of wacker5044N with a particle diameter of 5 μm, 1.2 parts of PCA-I carboxylic acid high-performance water reducing agent, the solid content of the water reducing agent is 40wt%, and the water reducing rate is 45%. Based on the water-binder ratio of 0.32, add water.

[0063]Modified polypropylene fiber is obtained by modifying polypropylene 6820 with 7008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water permeability coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com