An Alkali-resistant Foaming Agent and Its Application in Foamed Concrete

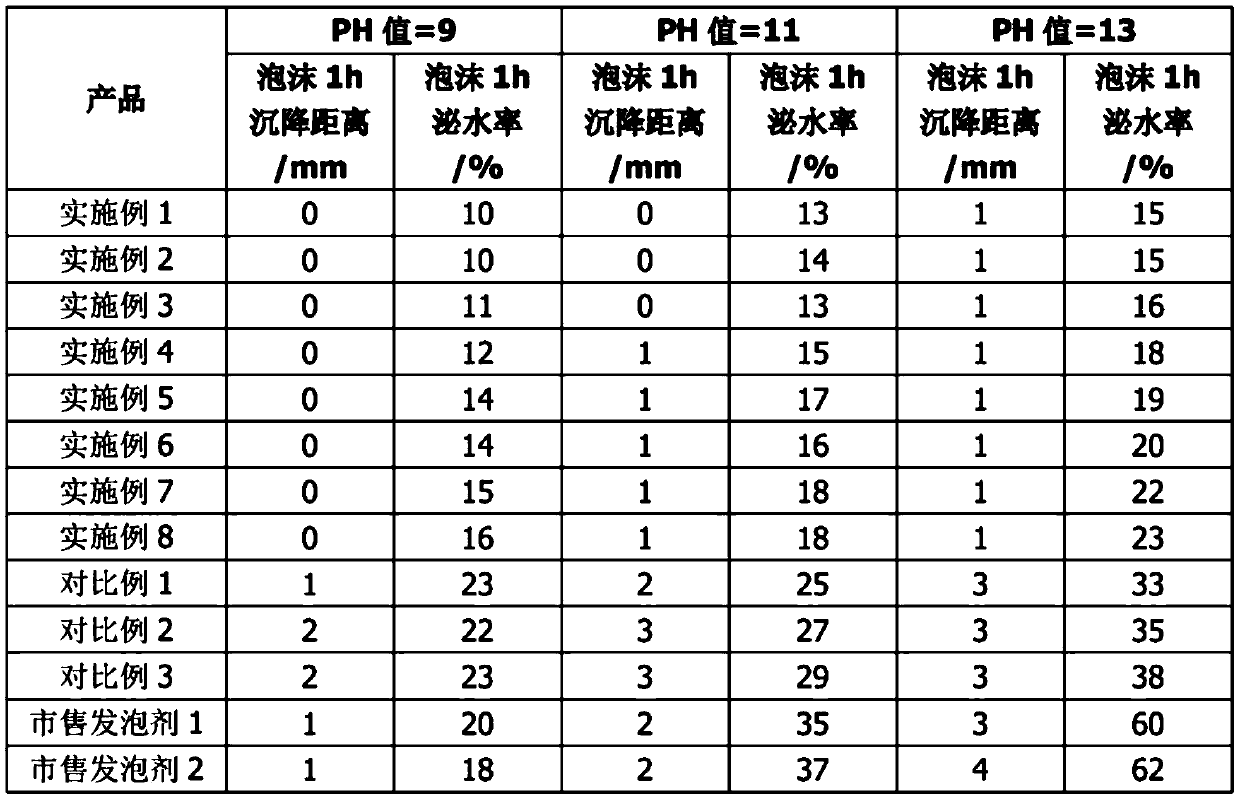

A foaming agent and alkali-resistant technology, applied in the field of foaming concrete foaming agent, can solve the problems of fluctuations in foam production capacity and foam stability, fluctuations in the alkalinity value of cement mixture, and affecting the foaming performance of the foaming agent , to achieve the effect of good foam stability, rich foam and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An alkali-resistant foaming agent, comprising the following raw materials in parts by weight: 5 parts of sodium lauryl aminopropionate, 6 parts of alkyl betaines, 5 parts of alkyl amine oxides, 0.8 parts of triethanolamine, 1 part of cellulose ether, 62 parts of water. 79.8

[0031] The alkyl betaine is lauryl dimethyl betaine, the alkyl amine oxide is hexadecyl dimethyl amine oxide, the cellulose ether is hydroxypropyl methyl cellulose ether, and the viscosity is It is 30000mpa.s.

Embodiment 2

[0033] An alkali-resistant foaming agent, comprising the following raw materials in parts by weight: 6 parts of sodium lauryl aminopropionate, 5.5 parts of alkyl betaines, 6.5 parts of alkylamine oxides, 1.1 parts of lauryl alcohol, and 0.7 parts of cellulose ether , 59 parts of water. 78.8

[0034] The alkyl betaine is octadecyl dihydroxyethyl betaine, the alkyl amine oxide is dodecyl dihydroxyethyl amine oxide, and the cellulose ether is hydroxypropyl methyl cellulose ether , the viscosity is 30000mpa.s.

Embodiment 3

[0036] An alkali-resistant foaming agent, comprising the following raw materials in parts by weight: 5.5 parts of sodium lauryl aminopropionate, 6.8 parts of alkyl betaines, 5.6 parts of alkyl amine oxides, lauryl alcohol and stearyl alcohol in any proportion 0.9 parts of the mixture, 1.1 parts of cellulose ether, and 70 parts of water. 89.9

[0037]The alkyl betaine is a mixture of dodecyl dimethyl betaine and dodecyl dihydroxyethyl betaine in any proportion, and the alkyl amine oxide is hexadecyl dimethyl amine oxide , the cellulose ether is hydroxypropyl methylcellulose ether with a viscosity of 30000mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com