Solid propellant taking polyester-butyl hydroxyl block polymer as adhesive

A solid propellant, butylated hydroxy block technology, applied in the field of rocket propellants, can solve the problems such as the melting characteristics of block polymers that have not been studied, the incompatibility of block polymers with plasticizers, and the poor mechanical properties of propellants. , to achieve the effect of improving low vulnerability performance, improving slow baking characteristics, and improving melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

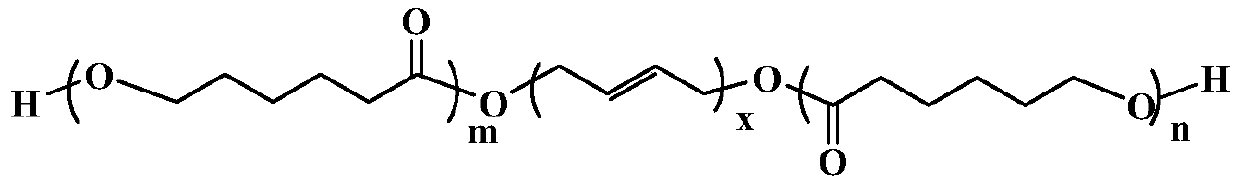

[0033] A kind of solid propellant, take polyester-butylene hydroxyl block polymer as binding agent, the structure of polyester-butylene hydroxyl block polymer is as follows:

[0034]

[0035] The propellant formula (each component is by mass percentage) with this block polymer as binder is as shown in Table 1:

[0036] Table 1 is the propellant formulation of binder with polyester-butylene hydroxyl block polymer

[0037]

[0038] The solid content of the propellant with the above-mentioned energetic plasticizer and the polyester-butylene hydroxyl block polymer as the binder is as high as 87%, and the propellant process performance is good, and if the block polymer is replaced by the butylated hydroxyl rubber , The process performance of the propellant is poor, indicating that the energetic plasticizer bis-2,2-dinitrododecyl formal only has good compatibility with block polymers. The mechanical properties and propellant density of the obtained propellants are shown in Ta...

Embodiment 2

[0044] A kind of solid propellant, with polyester-butylene hydroxyl block polymer as binder, its structure is:

[0045]

[0046] The propellant formula (each component is by mass percentage) with this block polymer as binder is as shown in table 3:

[0047] Table 3 is the propellant formulation of binder with polyester-butylene hydroxyl block polymer

[0048]

[0049] In formula 2, the propellant with polyester-butylene hydroxyl block polymer as the binder has a solid content of 86.5%, TDI is used as the curing agent, and it is mixed for 90 minutes at 50°C. The technological properties of the obtained propellant slurry are as follows: Table 4 shows.

[0050] Table 4 Process performance of propellant slurry

[0051] Numbering time, h 1h 3h 5h Recipe 2 η / Pa·s 409.7 493.3 758.0

[0052] It can be seen from Table 4 that the viscosity of the propellant after heat preservation at 50°C for 5 hours is only 758 Pa·s, which can meet the needs of exp...

Embodiment 3

[0058] A kind of solid propellant, with polyester-butylene hydroxyl block polymer as binder, its structure is:

[0059]

[0060] The propellant formula (each component is by mass percentage) with this block polymer as binder is as shown in table 6:

[0061] Table 6 is the propellant formulation of binder with polyester-butylene hydroxyl block polymer

[0062]

[0063] The solid content of formula 3 is 85.5%, and the mechanical properties of the obtained propellant are shown in Table 7.

[0064] Table 7 takes polyester-butylene hydroxyl block polymer as the mechanical property of the propellant of binding agent

[0065]

[0066] It can be seen from Table 7 that the mechanical properties of the propellant are excellent, and the elongation at room temperature, high temperature and low temperature is all greater than 45%, which can meet the needs of practical applications.

[0067] In addition, the state of the film made of this block polymer after heating to 400°C is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com