Tantalum-silicon alloy sputtering target material and preparation method thereof

A sputtering target, tantalum-silicon technology, applied in the field of tantalum-silicon alloy sputtering target and its preparation, can solve the requirements of density and internal structure uniformity of tantalum-silicon alloy sputtering target, melting point and Physical properties such as specific gravity vary greatly, and the purity requirements of the final sputtering target cannot be guaranteed, so as to achieve uniform internal structure, reduce cost investment, and prevent direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

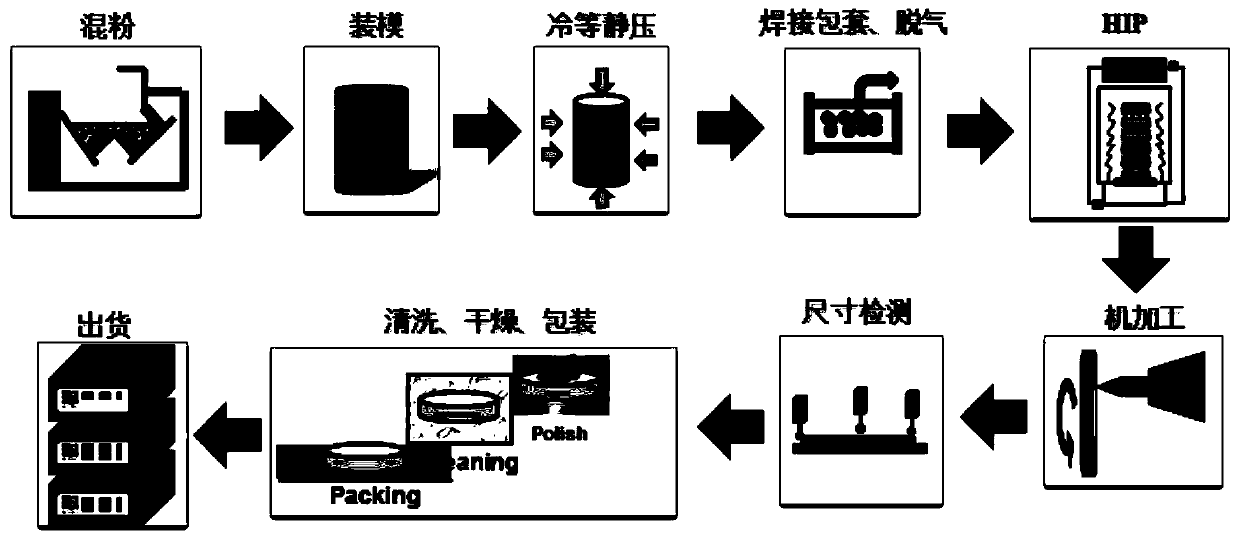

[0070] figure 1 A flowchart showing a method for preparing a tantalum-silicon alloy sputtering target provided by the present invention specifically includes the following steps:

[0071] (1) tantalum powder and silicon powder are mixed;

[0072] (2) the mixed tantalum-silicon powder of step (1) is molded and sealed;

[0073] (3) carrying out cold isostatic pressing to the mold after step (2) sealing to obtain a tantalum-silicon blank;

[0074] (4) passing the tantalum-silicon blank obtained in step (3) through a welding sheath, and then carrying out degassing treatment;

[0075] (5) hot isostatic pressing the sheath after degassing in step (4) at 1050-1350° C. to obtain a crude tantalum-silicon alloy sputtering target;

[0076] (6) Machining the crude tantalum-silicon alloy sputtering target obtained in step (5) to obtain a tantalum-silicon alloy sputtering target;

[0077] (7) The tantalum-silicon alloy sputtering target obtained in step (6) is subjected to size detectio...

Embodiment 1

[0081] This embodiment provides a method for preparing a tantalum-silicon alloy sputtering target, comprising the following steps:

[0082] (1) Put tantalum powder and silicon powder into the V-type powder mixer with polyurethane lining according to the atomic ratio of Si(at%)=50%, and under the protection of argon gas with a pressure of 0.04MPa, the Mix at a mixing rate of min for 36 hours. During the mixing period, every 6 hours, stop the machine and beat the V-shaped mixer with a rubber hammer;

[0083] (2) After putting the tantalum silicon powder mixed in step (1) into the rubber sleeve mould, tamp it with a tool, and then seal it;

[0084] (3) Put the rubber sleeve mold sealed in step (2) into a cold isostatic pressing machine, pressurize to 200MPa and keep the pressure for 15min for cold isostatic pressing to obtain a tantalum-silicon blank;

[0085] (4) Put the tantalum silicon blank obtained in step (3) into a stainless steel sheath, use argon arc welding to weld the...

Embodiment 2

[0091] This embodiment provides a method for preparing a tantalum-silicon alloy sputtering target, comprising the following steps:

[0092] (1) Put tantalum powder and silicon powder into the V-type powder mixer with polyurethane lining according to the atomic ratio of Si(at%)=50%. Under the protection of argon gas with a pressure of 0.05MPa, the The mixing rate of min was mixed for 20 hours, and there was no shutdown or beating treatment during the mixing period;

[0093] (2) After putting the tantalum silicon powder mixed in step (1) into the rubber sleeve mould, tamp it with a tool, and then seal it;

[0094](3) Put the rubber sleeve mold sealed in step (2) into a cold isostatic pressing machine, pressurize to 160MPa and hold the pressure for 20min to carry out cold isostatic pressing to obtain a tantalum silicon blank;

[0095] (4) Put the tantalum silicon blank obtained in step (3) into a stainless steel sheath, use argon arc welding to weld the stainless steel cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com