Preparation method of dispersion resins filled with polytetrafluoroethylene

A technology of polytetrafluoroethylene and dispersed resin, which is applied in the field of preparation of organic polymer compounds, can solve the problems of uniformity of color of filled PTFE, difficulty in controlling electrical conductivity, etc., and achieve simple and easy-to-operate industrial process, good resin processing performance, and filler separate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) In a 5L coagulation bucket (cylindrical, length-to-diameter ratio 2.5:1, 3 layers of stirring blades, six-blade straight paddle), add 3.5L of polytetrafluoroethylene emulsion with a specific gravity of 1.04, and add a surfactant linear secondary Alcohol polyoxyethylene ether (15-S-9, DOW company) 0.74g (3‰), mechanically stirred at 30rpm for 2min and mixed evenly.

[0033] 2) Add 0.48 g (0.2%) of graphite to the polytetrafluoroethylene emulsion obtained in step 1), and mechanically stir at 50 rpm for 10 minutes to obtain an emulsified polytetrafluoroethylene emulsion.

[0034] 3) Add 8 g of electrolyte ammonium bicarbonate to the polytetrafluoroethylene emulsion obtained in step 2), stir at 100 rpm for 5 minutes to obtain filled polytetrafluoroethylene powder, filter the water, wash, and dry in an oven at 160 ° C for 10 hours to obtain filled polytetrafluoroethylene dispersion resin.

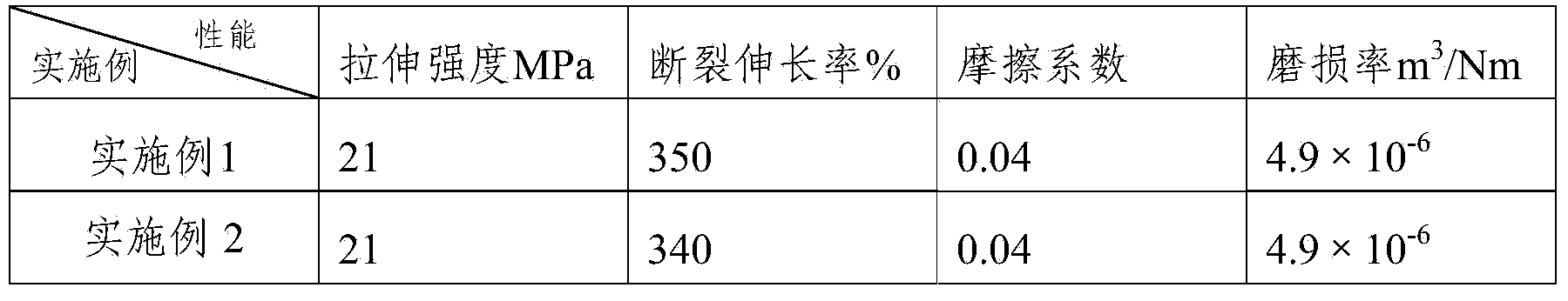

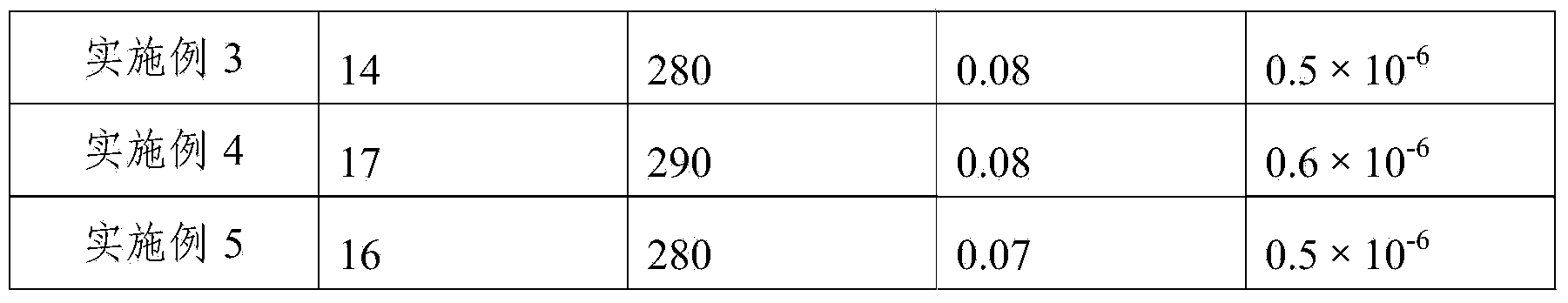

[0035] Embodiment 1 obtains resin 240g, gets four parts of samples, measures fill...

Embodiment 2

[0037] 1) Add 3.5L of polytetrafluoroethylene emulsion with a specific gravity of 1.08 to the 5L coagulation bucket (cylindrical, length-to-diameter ratio 2.5:1, 3 layers of stirring blades, six-blade straight paddle), add surfactant branched chain secondary Alcohol polyoxyethylene ether (TMN-6, DOW company) 1.48g (3‰), mechanically stirred at 50rpm for 2min and mixed evenly.

[0038] 2) Add 1.0 g (0.2%) of carbon black to the polytetrafluoroethylene emulsion obtained in step 1), and mechanically stir at 50 rpm for 10 minutes to obtain an emulsified polytetrafluoroethylene emulsion.

[0039] 3) Add 8 g of electrolyte ammonium bicarbonate to the polytetrafluoroethylene emulsion obtained in step 2), stir at 120 rpm for 5 minutes to obtain filled polytetrafluoroethylene powder, filter the water, wash, and dry in an oven at 160 ° C for 10 hours to obtain filled polytetrafluoroethylene dispersion resin.

[0040] Embodiment 2 obtains resin 495g, gets four samples, measures filling ...

Embodiment 3

[0042] 1) Add 3.5L of polytetrafluoroethylene emulsion with a specific gravity of 1.04 to the 5L coagulation bucket (cylindrical, length-to-diameter ratio of 2.5:1, 3 layers of stirring blades, six-blade straight paddle), and add surfactant linear secondary Alcohol polyoxyethylene ether (15-S-9, DOW company) 1.24g (5‰ of the weight of polytetrafluoroethylene), mechanically stirred at 30rpm for 2min and mixed evenly.

[0043] 2) Add 99.2 g (40%) of graphite to the polytetrafluoroethylene emulsion obtained in step 1), and mechanically stir at 50 rpm for 10 minutes to obtain an emulsified polytetrafluoroethylene emulsion.

[0044] 3) Add 8 g of electrolyte ammonium bicarbonate to the polytetrafluoroethylene emulsion obtained in step 2), stir at 100 rpm for 5 minutes to obtain filled polytetrafluoroethylene powder, filter the water, wash, and dry in an oven at 160 ° C for 10 hours to obtain filled polytetrafluoroethylene dispersion resin.

[0045]Embodiment 3 obtains resin 247g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com