Lithium cobalt phosphate preparing method

A technology of lithium cobalt phosphate and phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as low crystallinity, achieve high compaction density, reduce costs, and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

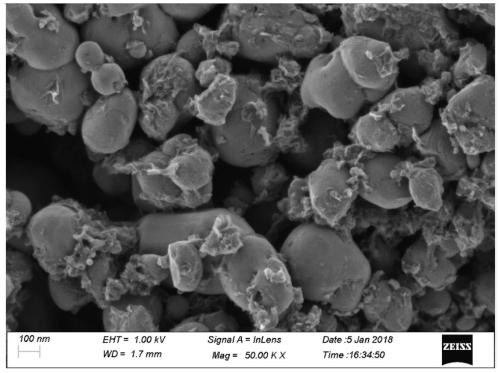

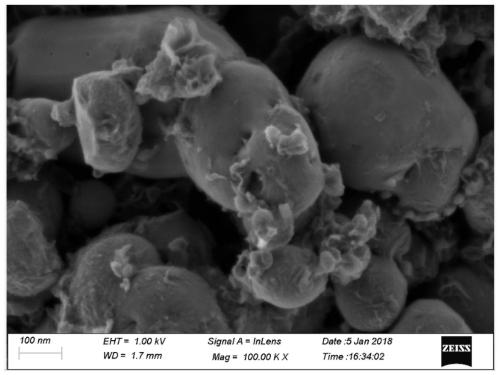

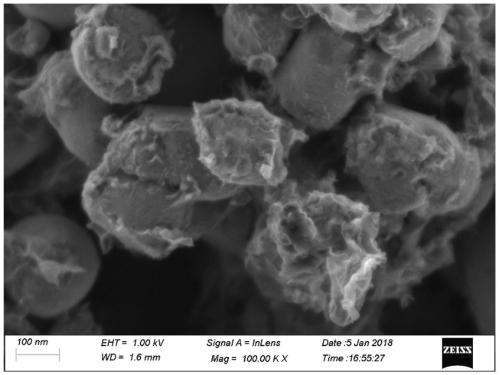

Image

Examples

Embodiment 1

[0041] A preparation method for lithium cobalt phosphate, which comprises the following steps:

[0042] (1) Add cobalt powder to phosphoric acid to dissolve, adjust the pH of the solution to 3.9, then finely filter to obtain cobalt solution, slurry lithium carbonate, and then pass into CO 2 Lithium carbonate slurry is completely clarified to obtain a lithium solution, prepare a polyethylene glycol solution, use the polyethylene glycol solution as a bottom solution, add the cobalt solution and lithium solution to the bottom solution under stirring, and continue the reaction after the addition is complete 50min;

[0043] (2) The material after the reaction of step (1) is spray-dried to obtain a spray-dried material, and the spray-dried material is put into a roller furnace, and nitrogen gas is introduced so that the oxygen content in the roller furnace is lower than 100ppm, and the material After passing through the heating section, heat preservation section and cooling section...

Embodiment 2

[0053] A preparation method for lithium cobalt phosphate, which comprises the following steps:

[0054] (1) Add cobalt powder to phosphoric acid to dissolve, adjust the pH of the solution to 3.9, then finely filter to obtain cobalt solution, slurry lithium carbonate, and then pass into CO 2 Lithium carbonate slurry is completely clarified to obtain a lithium solution, prepare a polyethylene glycol solution, use the polyethylene glycol solution as a bottom solution, add the cobalt solution and lithium solution to the bottom solution under stirring, and continue the reaction after the addition is complete 45min;

[0055] (2) The material after the reaction of step (1) is spray-dried to obtain a spray-dried material, and the spray-dried material is put into a roller furnace, and nitrogen gas is introduced so that the oxygen content in the roller furnace is lower than 100ppm, and the material After passing through the heating section, heat preservation section and cooling section...

Embodiment 3

[0065] A preparation method for lithium cobalt phosphate, which comprises the following steps:

[0066] (1) Add cobalt powder to phosphoric acid to dissolve, adjust the pH of the solution to 4.3, then finely filter to obtain cobalt solution, slurry lithium carbonate, and then pass into CO 2 Lithium carbonate slurry is completely clarified to obtain a lithium solution, prepare a polyethylene glycol solution, use the polyethylene glycol solution as a bottom solution, add the cobalt solution and lithium solution to the bottom solution under stirring, and continue the reaction after the addition is complete 40min;

[0067] (2) The material after the reaction of step (1) is spray-dried to obtain a spray-dried material, and the spray-dried material is put into a roller furnace, and nitrogen gas is introduced so that the oxygen content in the roller furnace is lower than 100ppm, and the material After passing through the heating section, heat preservation section and cooling section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com