Coated modified electrode material and preparation method thereof

A technology of electrode materials and coating materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of surface coating layer damage, affecting material performance, etc., to reduce usage, improve uniformity, and balance airflow distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

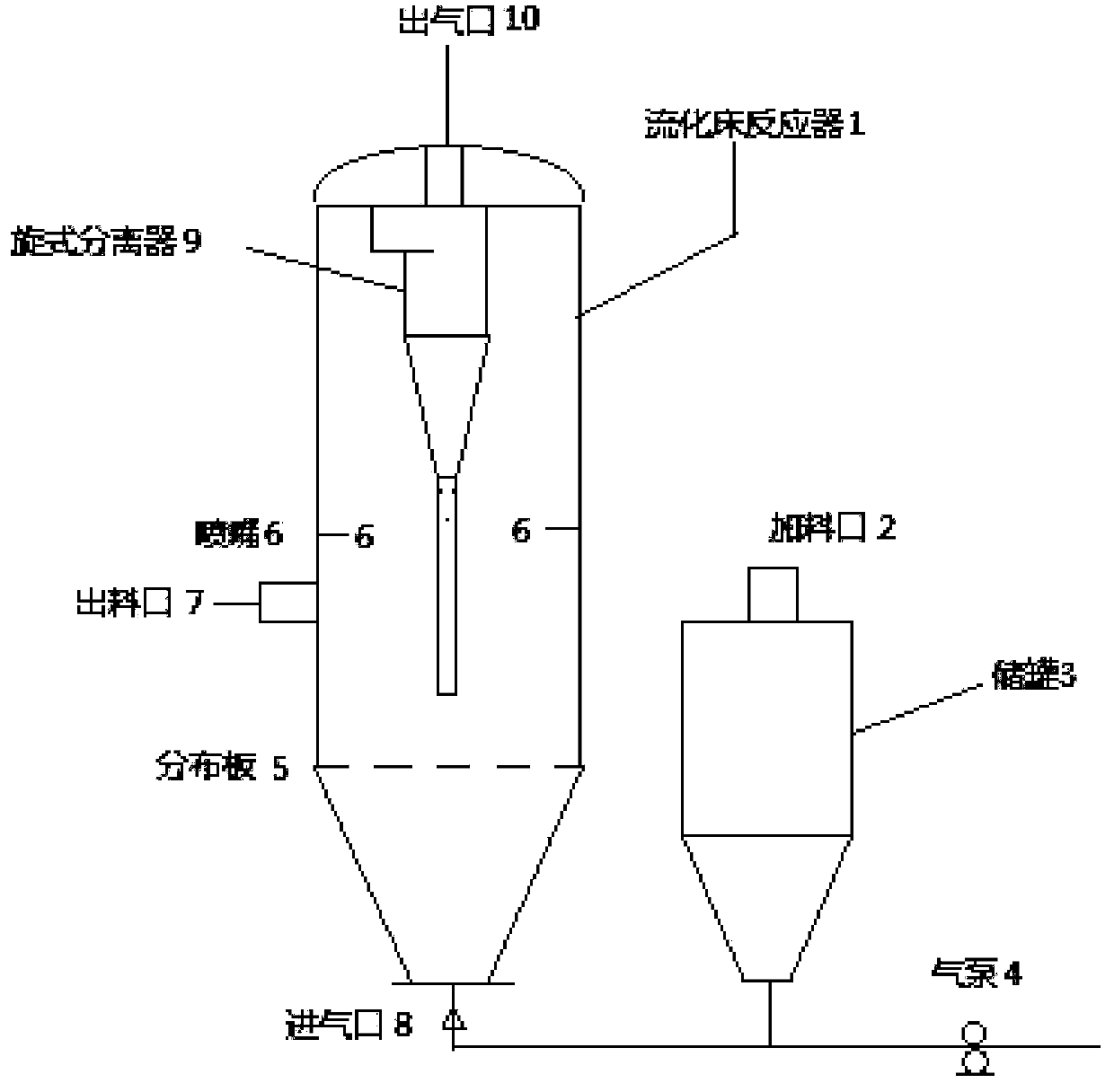

[0086] This embodiment provides a fluidized bed and a method of using the fluidized bed to mix the coating material precursor and the positive electrode material first, and then sinter to prepare the coated modified electrode material.

[0087] (1), the structural representation of described fluidized bed is as figure 1 As shown, it includes fluidized bed reactor 1, feed inlet 2, storage tank 3, gas pump 4, gas distribution plate 5, nozzle 6, material outlet 7, air inlet 8, cyclone separator 9 and gas outlet 10 ;

[0088] Wherein, the gas inlet 8 of the fluidized bed reactor 1 is connected to the air pump 4 through a pipeline, the pipeline between the gas inlet 8 and the gas pump 4 is provided with a storage tank 3 and is connected through the outlet of the storage tank 3, The top of the storage tank 3 is provided with a feeding port 2;

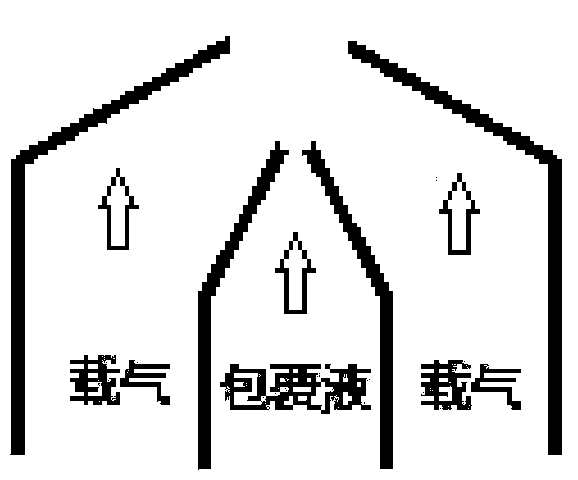

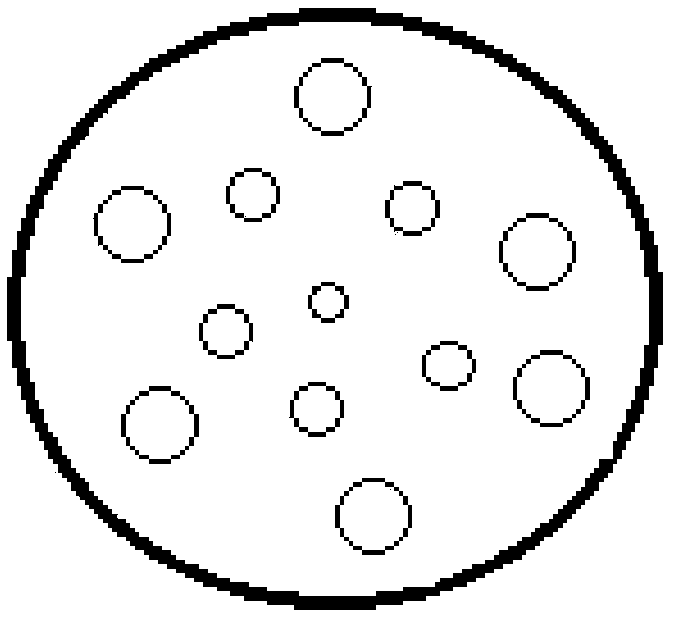

[0089] The shape of the gas distribution plate 5 is the same as the cross-sectional shape of the fluidized bed reactor 1 , and is fixed on...

Embodiment 2

[0107] The fluidized bed used is the same as that in Example 1, the difference being that a positive electrode material coated with titanium oxide is prepared, and the preparation process is as follows:

[0108] 1. Preparation of coating solution

[0109] 24g of tetrabutyl titanate, 46g of absolute ethanol, and 100g of simethicone were weighed and mixed to prepare a coating solution.

[0110] 2. Coating process

[0111] (a) Weigh 1000g of nickel-cobalt-manganese ternary 523 cathode material and add it to the storage tank 3 from the feed port 2, and the compressed air with an initial velocity of 1.7m / s sends the cathode material from the air inlet 8 into the fluidized bed reaction through the air pump 4 Device 1, and through the gas distribution plate 5;

[0112] (b) adjust the gas flow rate to be 0.9m / s, so that the positive electrode material forms a stable bed (distributed fluidization) in the fluidized bed reactor 1;

[0113] (c) After the positive electrode material in ...

Embodiment 3

[0121] The fluidized bed, coating method and sintering method adopted are the same as in Example 1, the difference being that in the process of preparing the coated modified cathode material:

[0122] The coating liquid is an aluminum nitrate solution, and the mass fraction of aluminum nitrate is 5wt%;

[0123] Step (a) initial velocity is 2m / s; step (b) gas velocity is 1m / s; step (c) gas velocity is 6m / s.

[0124] The capacity retention rate of the coated material in Example 3 after 100 cycles is 92.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com