Preparation method of FD evaporative pattern plate and evaporative pattern plate prepared by preparation method

A lost foam and plate technology, which is used in flat products, casting molding equipment, other household appliances, etc., can solve the problems of pouring and reverse injection, the quality of castings is reduced, and it is not easy to thermally decompose, so as to ensure full fusion, reduce gas generation, and improve The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A preparation method of FD disappearing template material, is characterized in that, comprises the following steps:

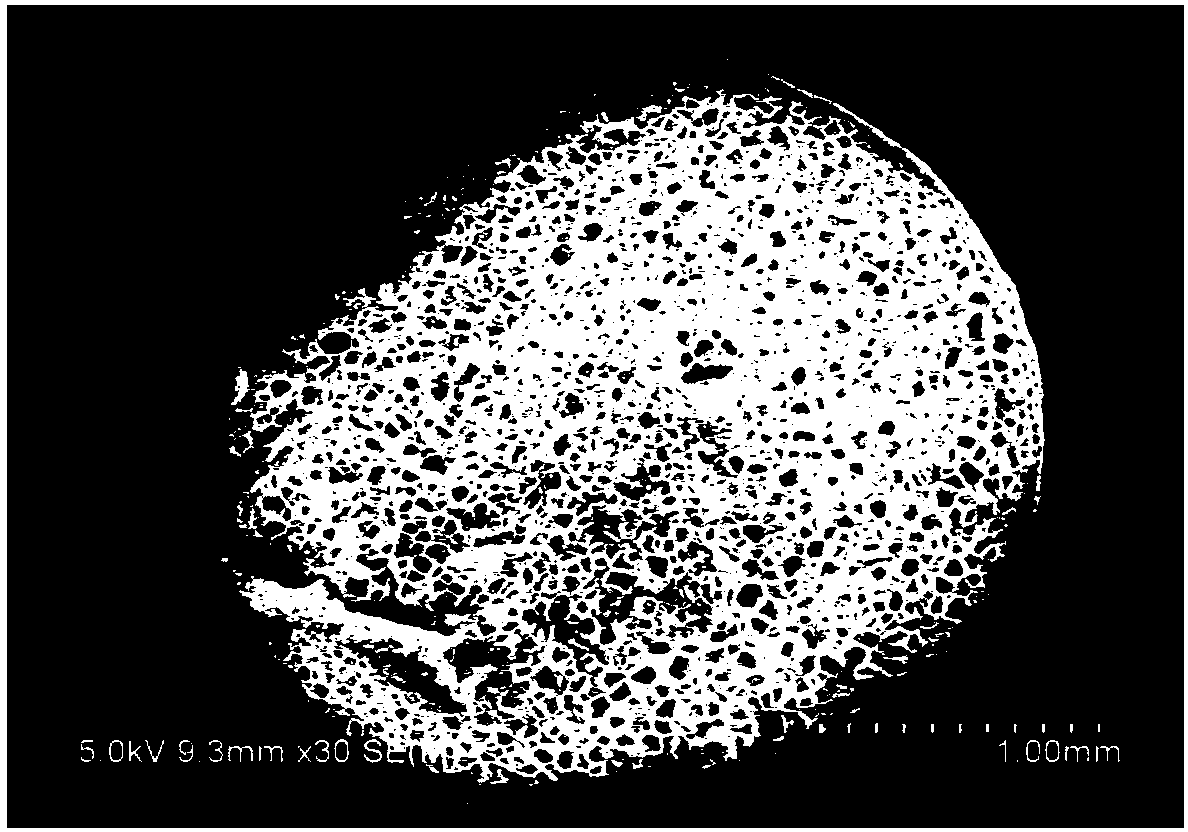

[0059] (1) Selection of beads: select FD with a particle size between 0.9mm as the original beads;

[0060] (2) Pre-foaming: Pressurized foaming is adopted, and the above-mentioned FD beads are added to the SPJ1500 automatic intermittent pressurized quantitative pre-foaming machine for pre-foaming. The pressure of the firing furnace is 0.013-0.018Mpa; the main steam pressure The steam pressure is 0.66~0.72Mpa, the steam adjustment pressure is 0.7~0.8Mpa, the temperature of the steam is 100°C, the steam enters the pre-foaming machine through the gas tank to accelerate the steam pre-foaming time, and is stirred in the pre-foaming chamber Stir continuously with the device, so that the FD primary beads to be foamed are in a liquid state or the viscosity reaches a plastic state before foaming. The pre-foaming time is 150-165s per 28kg of FD beads;

[0061] (...

Embodiment 2

[0069] A preparation method of FD disappearing template material, is characterized in that, comprises the following steps:

[0070] (1) Selection of beads: select FD with a particle size between 1.25mm as the original beads;

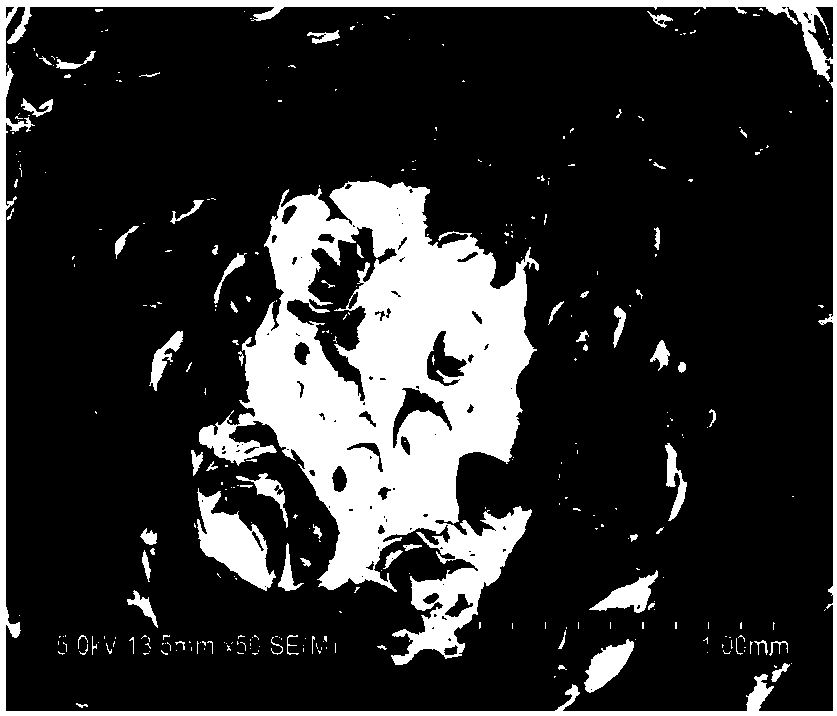

[0071] (2) Pre-foaming: Pressurized foaming is adopted, and the above-mentioned FD beads are added to the SPJ1500 automatic intermittent pressurized quantitative pre-foaming machine for pre-foaming. The pressure of the firing furnace is 0.013-0.018Mpa; the main steam pressure The steam pressure is 0.66~0.72Mpa, the steam adjustment pressure is 0.7~0.8Mpa, and the temperature of the steam is 100°C; the steam enters the pre-foaming machine through the gas storage tank to accelerate the steam pre-foaming time, and is stirred in the pre-foaming chamber Stir continuously with the device, so that the FD primary beads to be foamed are in a liquid state or the viscosity reaches a plastic state before foaming. The pre-foaming time is 150-165s per 28kg of FD beads...

Embodiment 3

[0080] A preparation method of FD disappearing template material, is characterized in that, comprises the following steps:

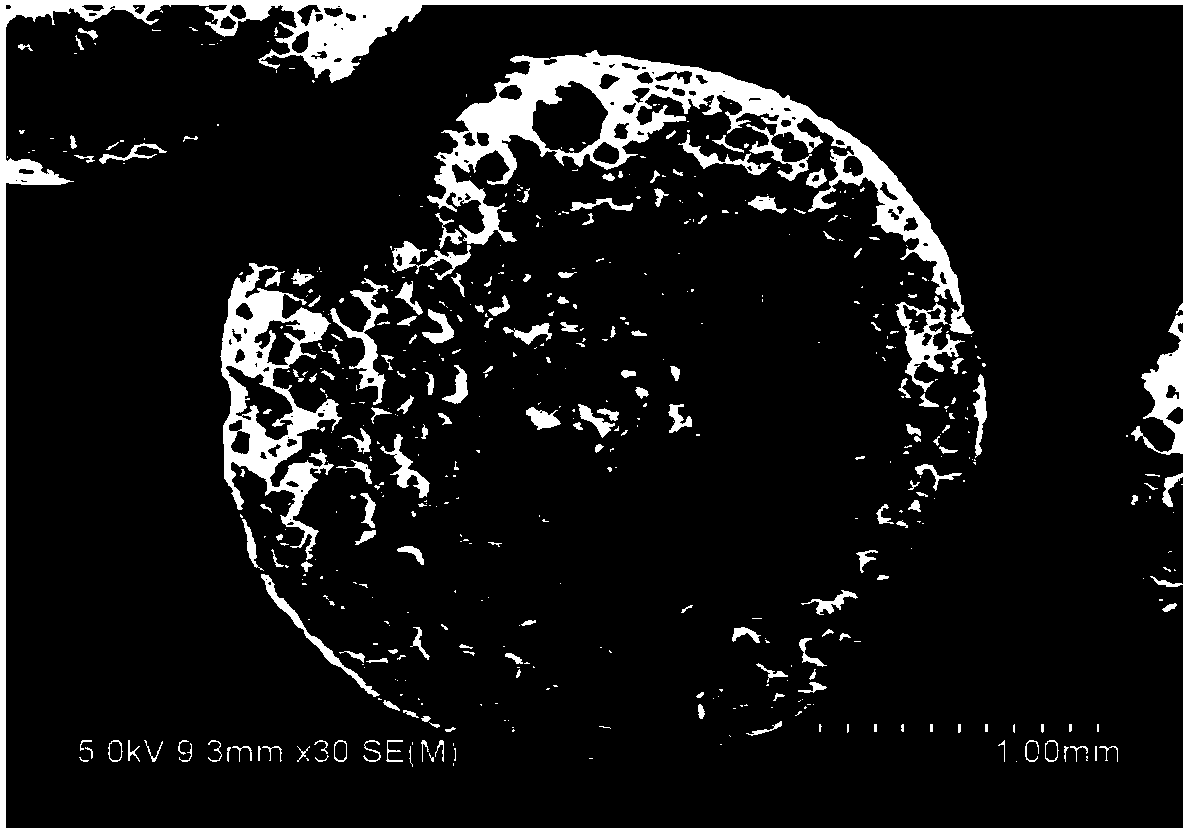

[0081] (1) Selection of beads: select FD with a particle size between 1.0mm as the original beads;

[0082] (2) Pre-foaming: Pressurized foaming is adopted, and the above-mentioned FD beads are added to the SPJ1500 automatic intermittent pressurized quantitative pre-foaming machine for pre-foaming. The pressure of the firing furnace is 0.013-0.018Mpa; the main steam pressure The steam pressure is 0.66~0.72Mpa, the steam adjustment pressure is 0.7~0.8Mpa, and the temperature of the steam is 100°C; the steam enters the pre-foaming machine through the gas storage tank to accelerate the steam pre-foaming time, and is stirred in the pre-foaming chamber Stir continuously with the machine, so that the FD original beads to be foamed are in a liquid state or the viscosity reaches a plastic state before foaming. The pre-foaming time is 150-165s per 28kg of FD bead...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com