Treatment of biological reactor for coking sewage membrane

A membrane bioreactor, coking sewage technology, applied in sustainable biological treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of complex regeneration process, high cost, unable to meet water quality requirements, etc. Achieve the effect of increasing volume load, realizing reuse, and saving land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

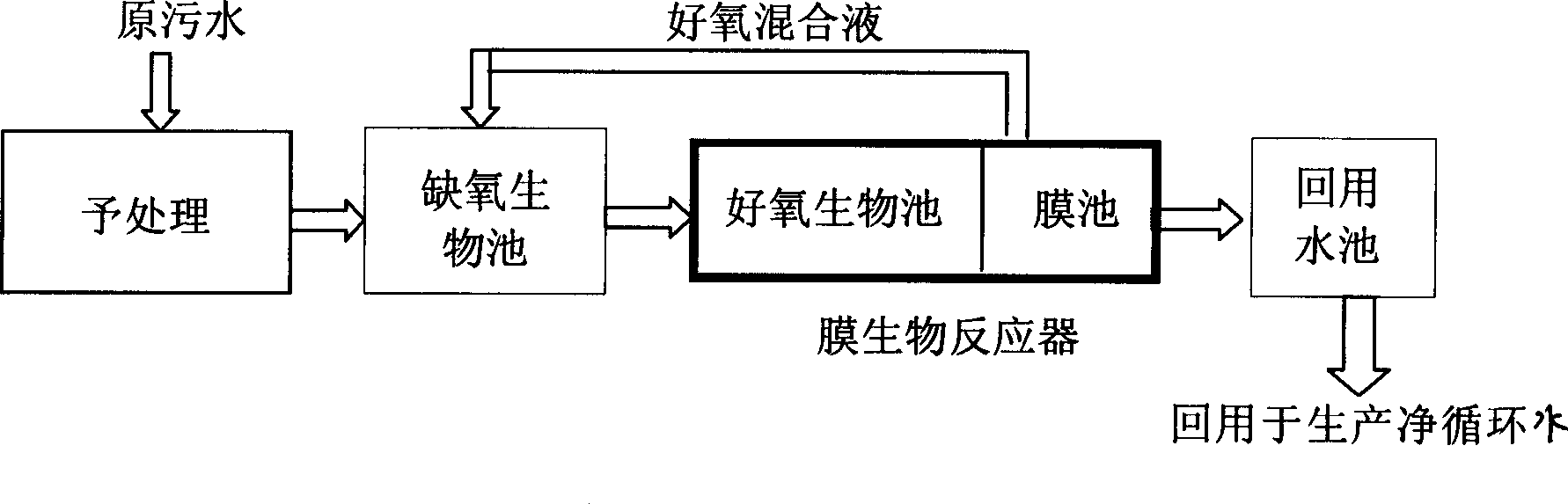

[0012] Raw sewage volume is 50m 3 / h, enter the biochemical treatment stage after pretreatment and degreasing. The biochemical treatment adopts the A / O external cycle biological denitrification process, and the sludge concentration in the aerobic biological pool is kept at 8g / L; the sludge load of the membrane bioreactor is 0.45kgCOD / kgMLVSS·d and 0.05kgTKN / kgMLVSS·d, the volume load is 2kgCOD / m 3 ·d and 0.2kgTKN / m 3 d; The aerobic effluent is filtered by the curtain microfiltration membrane installed in the membrane pool, and the total area of the microfiltration membrane is 4800m 2 , the water out of the membrane is sucked by pump negative pressure, the pressure is -0.02MPa, the water temperature is 20°C, and the water flux through the membrane is 10L / h·m 2 , the effluent enters the reuse pool after treatment. The curtain microfiltration membrane is equipped with 10 membrane boxes, and each membrane box contains 24 membrane elements (20m 2 / piece), 8 membrane boxes wo...

Embodiment 2

[0015] Raw sewage volume is 50m 3 / h, enter the biochemical treatment stage after pretreatment and degreasing. The biochemical treatment adopts the A / O external cycle biological denitrification process, and the sludge concentration in the aerobic biological pool is kept at 10g / L; the sludge load of the membrane bioreactor is 0.3kgCOD / kgMLVSS·d and 0.03kgTKN / kgMLVSS·d, the volume load is 2.7kgCOD / m 3 ·d and 0.28kgTKN / m 3 d; The aerobic effluent is filtered by the curtain ultrafiltration membrane installed in the membrane pool, and the total area of the ultrafiltration membrane is 5000m 2 , the water out of the membrane is sucked by pump negative pressure, the pressure is -0.03MPa, the water temperature is 20°C, and the water flux through the membrane is 15L / h·m 2 , the effluent enters the reuse pool after treatment. The curtain ultrafiltration membrane is equipped with 10 membrane boxes, and each membrane box contains 24 membrane elements (20m 2 / piece), 8 membrane boxes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com