Closed cyclic utilization method for production water of monoammonium phosphate

A closed-loop, monoammonium phosphate technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of large sewage discharge, high sewage treatment cost, and technical requirements for environmental protection water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

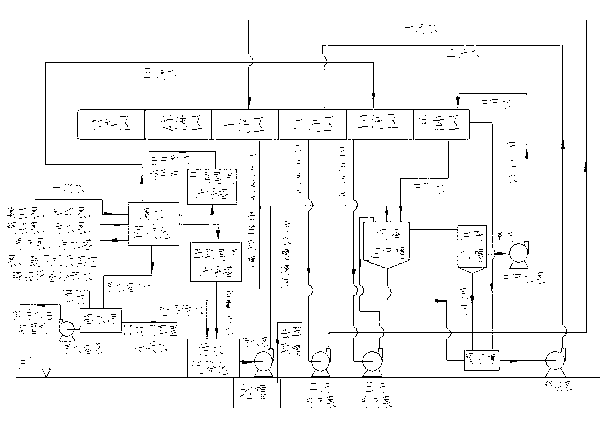

[0029] Such as figure 1 As shown, the present invention includes the following steps.

[0030] (a) Add water to the clear water recovery tank once;

[0031] (b) Recycling cooling water used for vacuum pumps, slurry pumps, thick slurry pumps, sewage pumps, filtrate pumps, cooling water tower pumps, blowers and other ammonium phosphate equipment to the clean water recovery tank;

[0032] (c) Transfer part of the clean water from the clean water recovery tank to vacuum pumps, slurry pumps, thick slurry pumps, sewage pumps, filtrate pumps, sewage pumps, blowers and other ammonium phosphate equipment to cool these equipment;

[0033] (d) Part of the clean water in the clean water recovery tank is sent to the extraction tail gas scrubber to wash the fluorine in the tail gas of the extraction tank to form fluorine-containing sewage, and then recover the fluorine-containing sewage to the sewage settling tank;

[0034] (e) Transfer part of the clean water from the clean water recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com