Integrated measuring apparatus of liquid level and material level

A measuring device and material technology, which is applied to buoy liquid level indicators, display liquid level indicators through weight measurement, etc., can solve the problems of high cost, high failure rate, single function, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

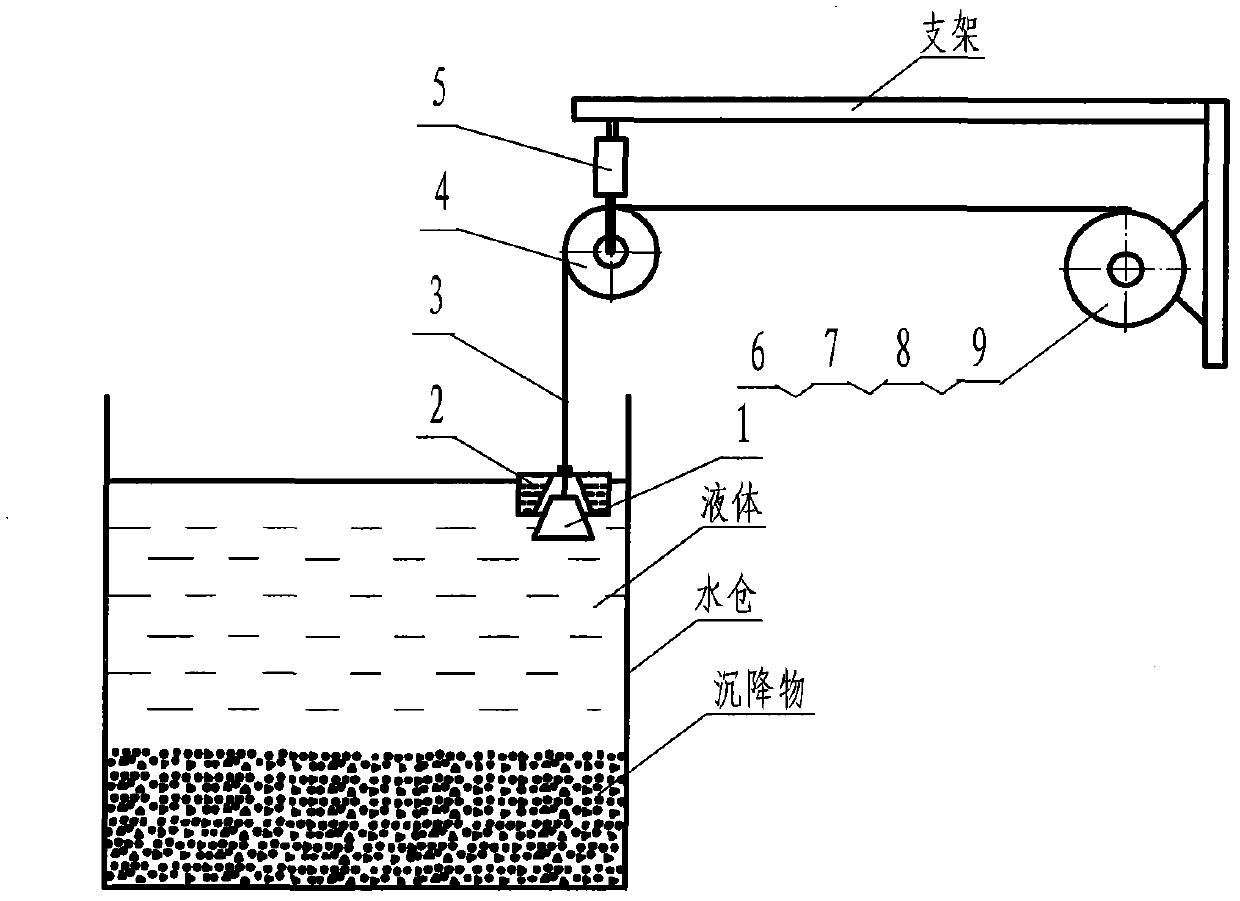

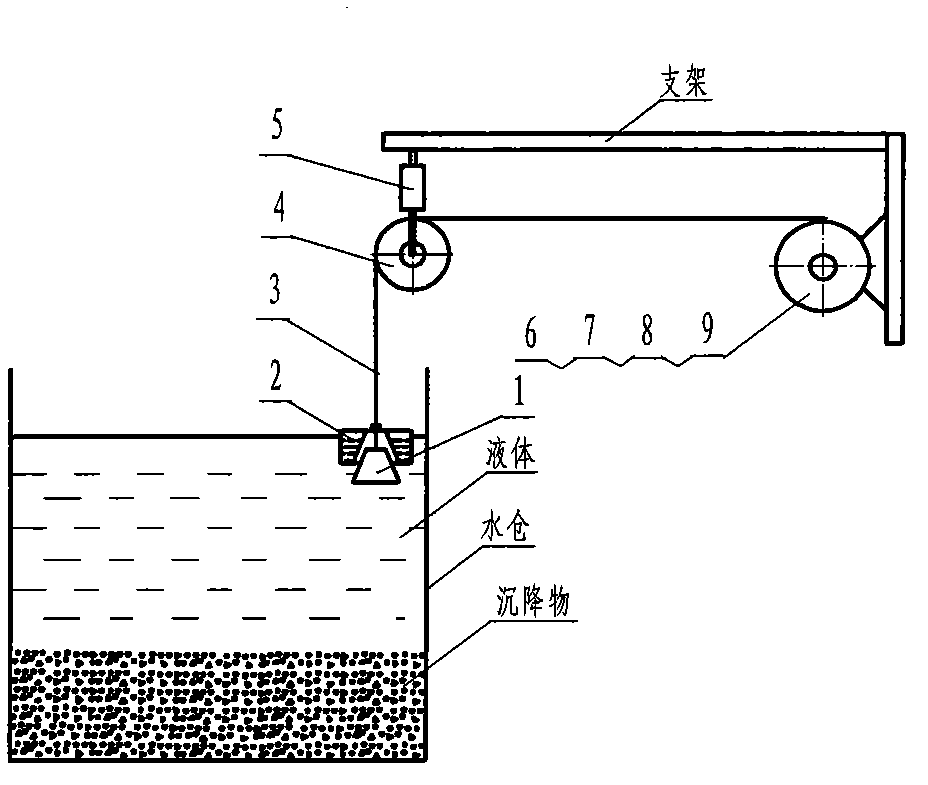

[0022] The application of the present invention on the sedimentation tank of sewage treatment plant, after the industrial and domestic sewage is sent to the sewage treatment plant, it must be settled in the sedimentation tank to remove the solids in the sewage before it can enter the next process for treatment, so it will be deposited at the bottom of the sedimentation tank A large amount of sludge, measuring the water level of the settling tank and the height of the sludge is required by the process.

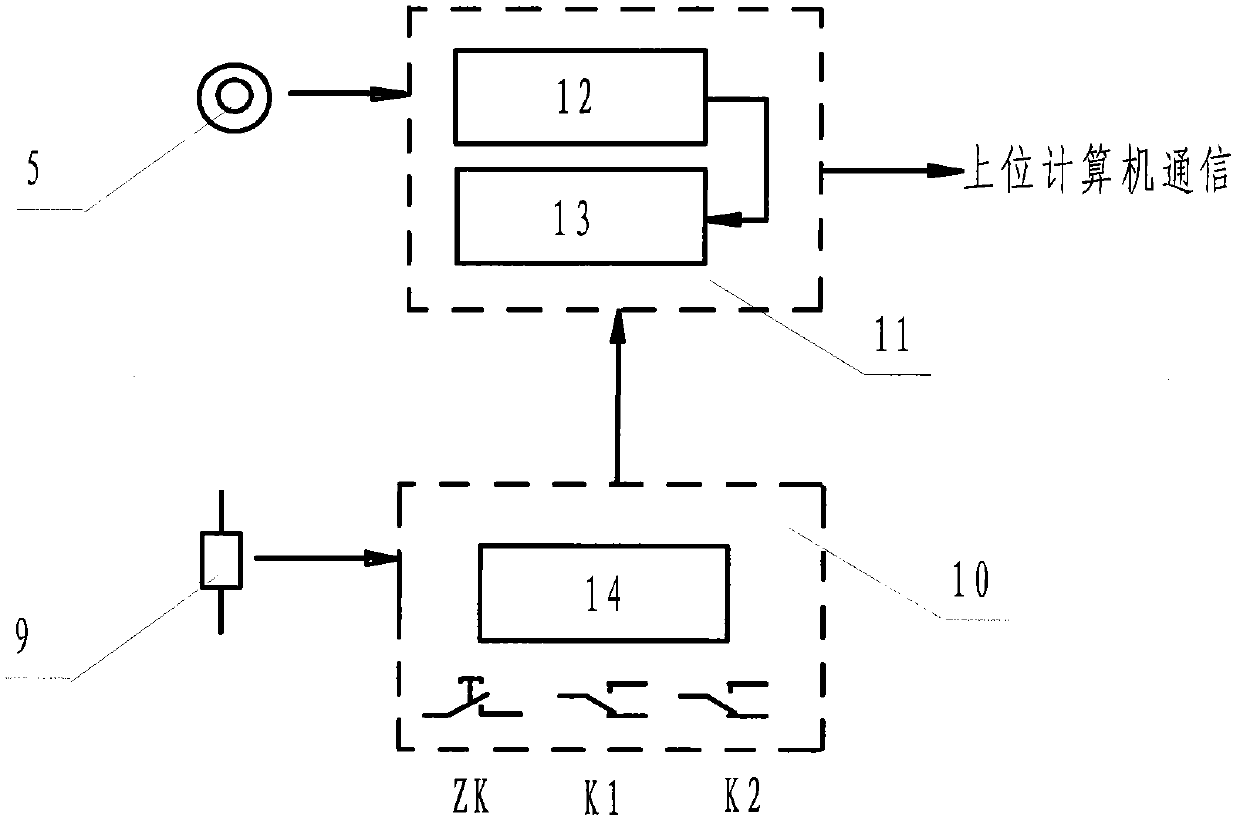

[0023] The whole device consists of probe, transmission system (see attached figure 1 ), control system and measurement system (see attached figure 2 ) consists of four parts, wherein the probe consists of two parts, the weight 1 and the buoy 2, the weight 1 is a metal conical solid body, the buoy 2 is a hollow cylinder welded by metal steel plates, and its central part is made to be the same as The cone angle and size of the hammer 1 are the same; the transmission system is ...

Embodiment approach 2

[0033] The application of the liquid level and material level integrated measuring device of the present invention in the underground water tank of the coal mine. A large amount of coal seam water will be generated during the coal mining process in the coal mine. This part of water needs to be recycled and reused for spraying and reducing dust by the coal cutting unit And hydraulic oil cooling, and this part of the water is mixed with a large amount of coal powder and must be precipitated before it can be used. The water tank is a special facility used to collect and precipitate coal seam water, so a large amount of coal slime will be deposited at the bottom of the water tank, and the water level of the water tank And the height of coal slime are two important parameters. When the coal slime reaches a certain height, it reminds the operator that it must be dredged in time. The whole set of measuring devices is installed on the tank wall of the water tank (see attached figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com