Integrated treatment process and equipment for river sediment dredging and residual water

A technology of treatment equipment and treatment process, which is applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, centrifuged water/sewage treatment, etc., can solve the problems of dredging sediment and residual water treatment, etc. High degree of integration, shortened time, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

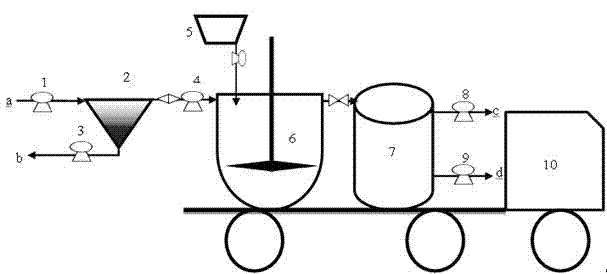

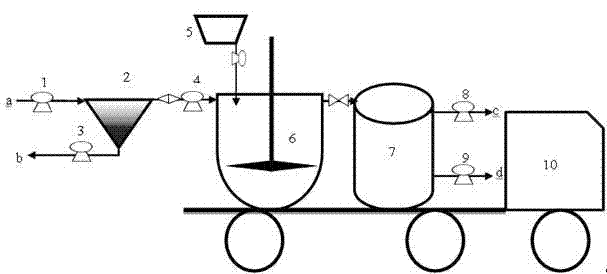

[0027] Embodiment 1: The specific method is to dredge the residual water of the sediment through the settling tank, and the settling time can be set according to the volume elasticity of the on-site settling tank. The effluent enters the stirring device 6, and at the same time, the flocculant ferric chloride at 10-20 mg / L and the coagulant PAM at 1.2-2.4 mg / L are added into the stirring device 6 with a peristaltic pump, and the stirrer in the stirring device 6 stirs The flocculant and coagulant are fully mixed with the remaining water after settlement, and the hydraulic retention time of the remaining water in the stirring device 6 is controlled between 2 minutes and 3 minutes. The water output from the stirring device 6 enters the centrifuge device 7, and after being centrifuged by the centrifuge device 7, bacteria, organic matter, neutral molecules, and small particles in the water are centrifugally settled in the form of coagulated flocs to ensure that the quality of the eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com