Constant water level sequencing batch active sludge process and system for treating sewage

An activated sludge and sequencing batch technology, applied in the field of sewage treatment, can solve the problems of low utilization rate of equipment and tank capacity, unstable dephosphorization and nitrogen removal effect, large head loss, etc., so as to reduce energy consumption and improve operation effect. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

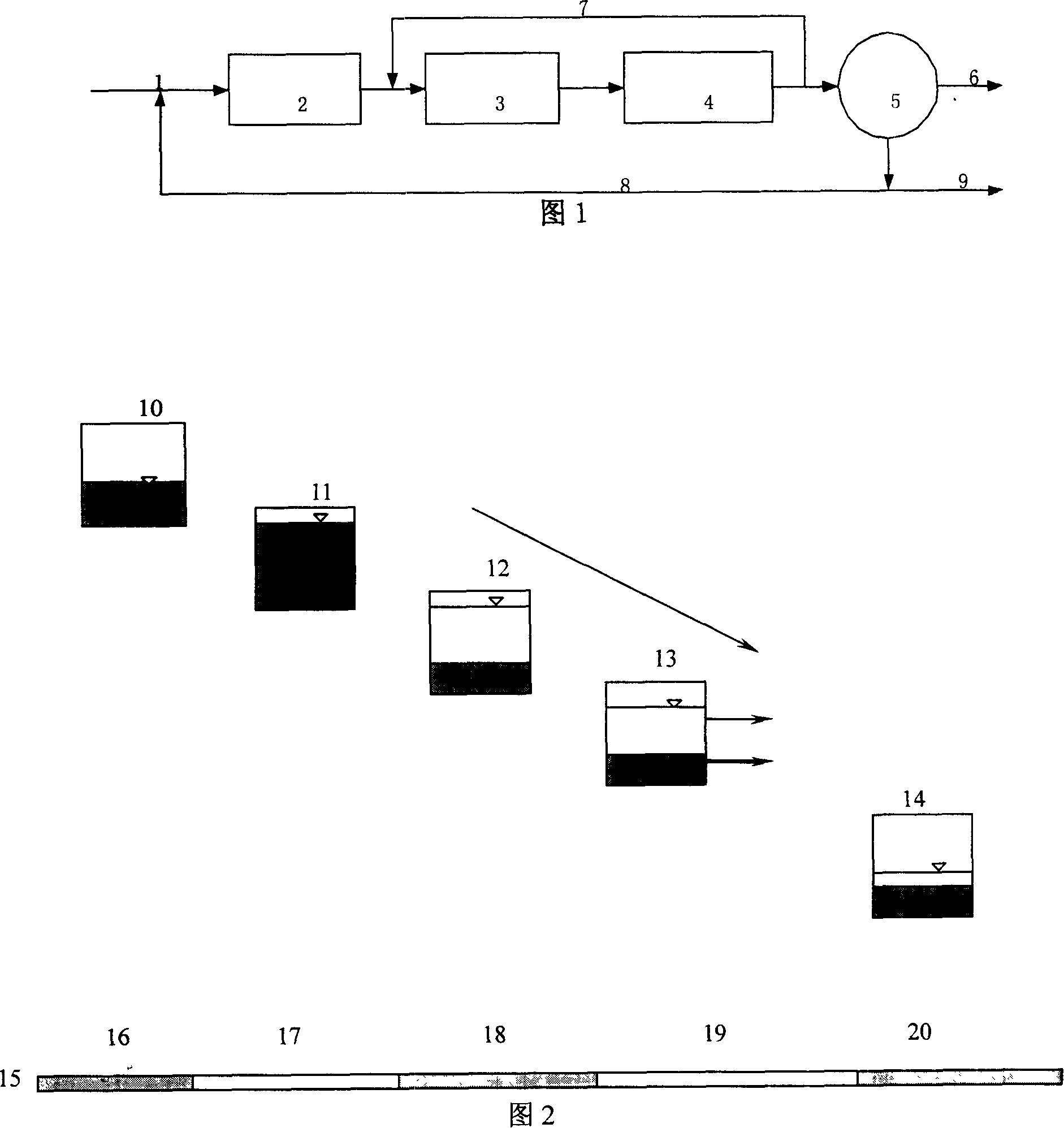

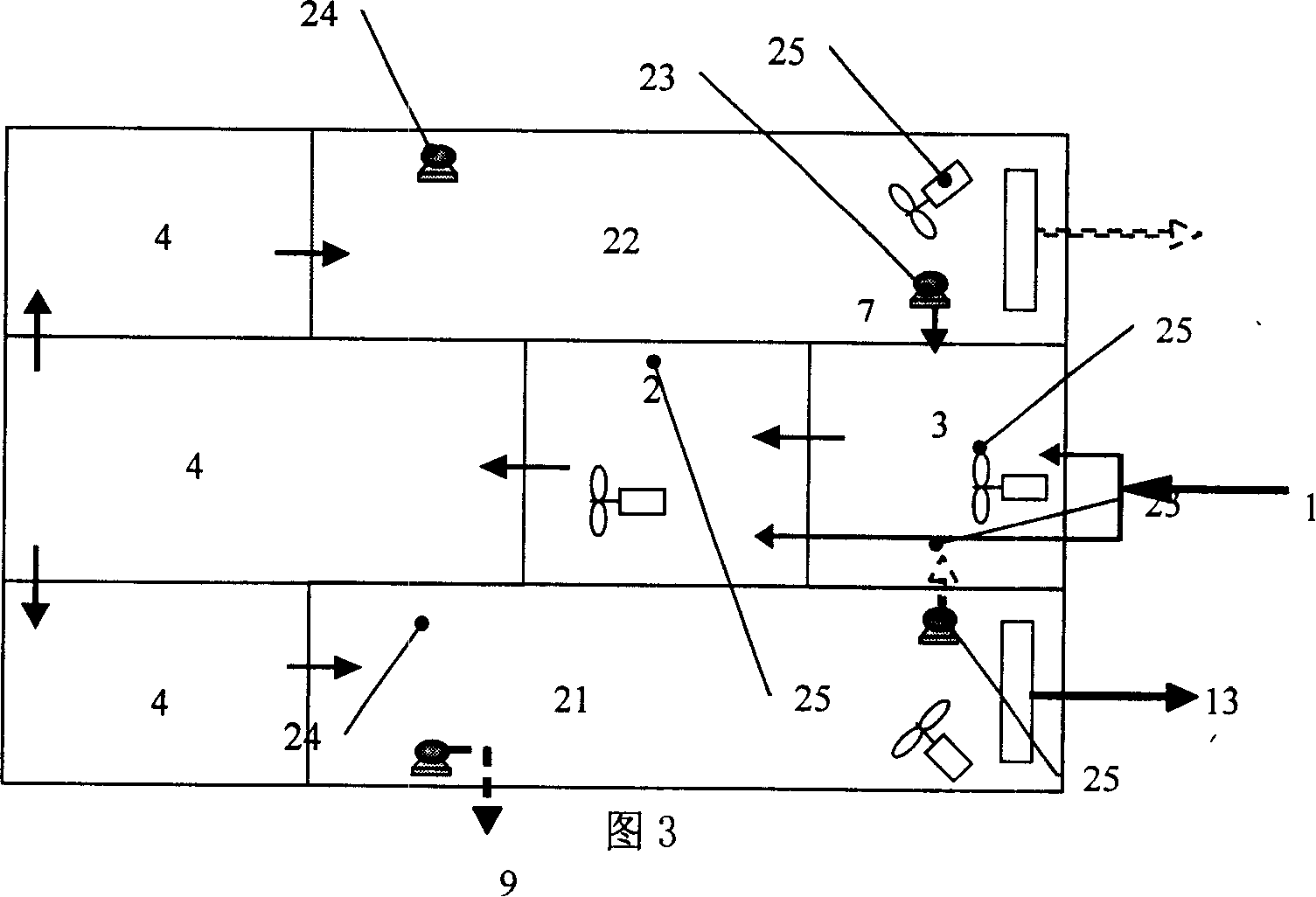

[0040] The method for treating sewage with constant water level sequencing batch type activated sludge proposed by the present invention first makes 10% to 30% of the pretreated sewage through the grid and grit chamber enter the anoxic pool, and removes the waste from the sequence batch pool in the anoxic pool The nitrate brought in the return sludge, the volume ratio of the return sludge to the total influent of the system, that is, the reflux ratio is 2 to 3:1, and the residence time is 1.0 to 2.0 hours; the sewage in the anoxic tank and the passing 70% to 90% of the pretreated sewage of the grid and the grit chamber enters the anaerobic tank together, and the two are mixed to make the phosphorus accumulating bacteria in it absorb the volatile acid produced by the hydrolysis and acidification of the sewage to release phosphorus, and the residence time is 1.5 to 2.0 Hours; make the sewage flow into the aerobic pool, degrade the organic matter in the sewage, remove the ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com