Method for processing and recycling drill cuttings

A recovery method and drilling cuttings technology, applied in the field of drilling waste treatment and recovery, can solve the problems of unrecoverable oil base, small amount of waste treatment, high operating cost, etc., to achieve reduced disposal costs, large amount of treatment, and low operating cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

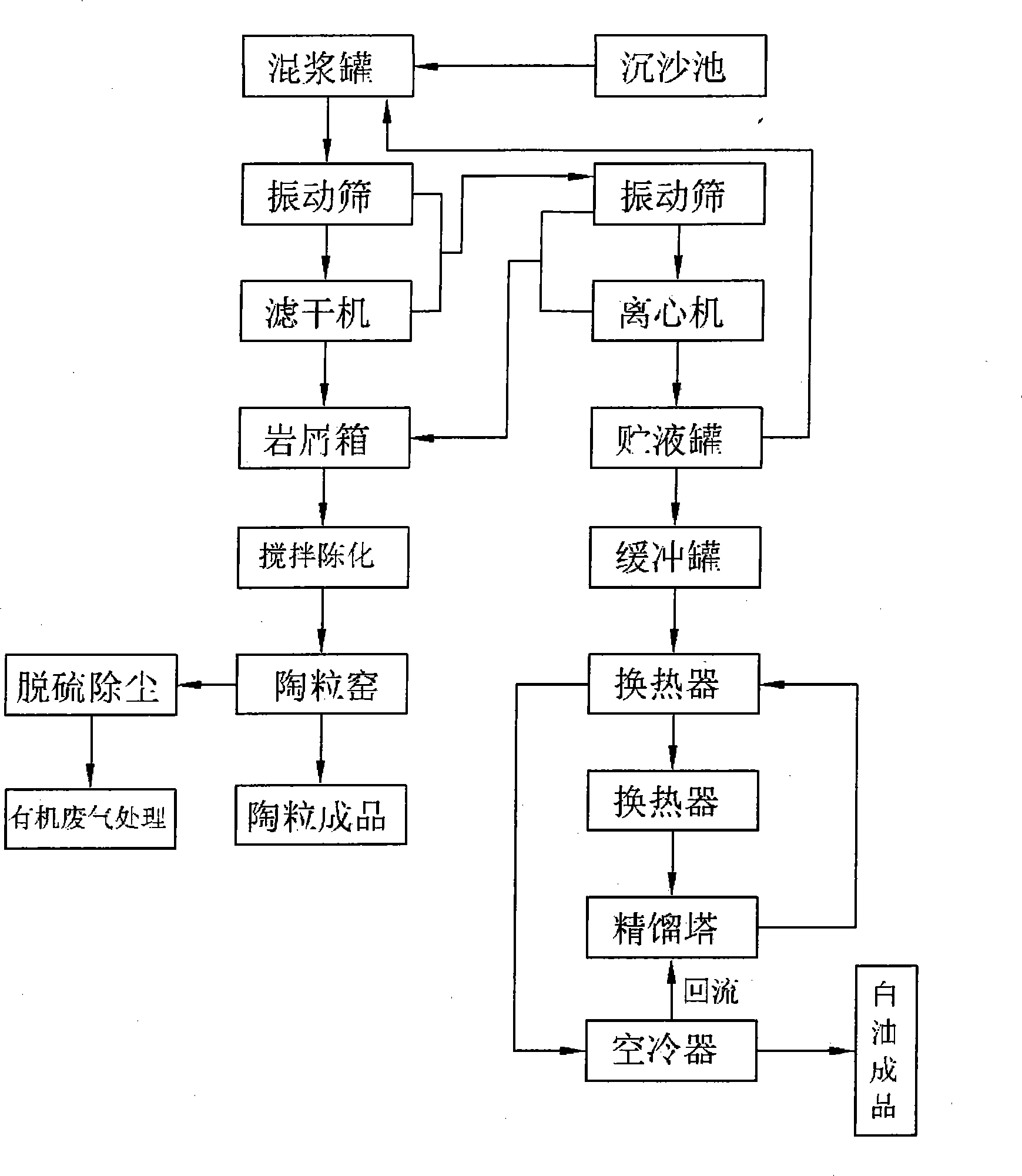

Image

Examples

Embodiment 1

[0020] Inject the oil-based drilling cuttings back to the shore into the grit chamber; pump the drill cuttings in the grit chamber into the mixing tank, and adjust the liquid-solid ratio in the mixing tank to be 4:1 by weight percentage; The mixed slurry in the mixing tank is pumped into the first vibrating screen for screening, wherein the concentration of the oversize is kept at 30% in weight percentage, and the mesh of the vibrating screen is 100 mesh; the first vibrating The undersize of the sieve freely falls into the filter dryer to filter dry, and the dried solid phase is sent to the screw conveyor to be transported to the salt dust box. The filter mesh of the filter dryer is 0.8mm; The undersize of a vibrating screen is combined with the overflow of the filter dryer and sent to the second vibrating screen; the oversize of the second vibrating screen falls into the screw conveyor and is transported to the salt dust box, and the undersize is Pumped into the centrifuge th...

Embodiment 2

[0022] Inject the oil-based drilling cuttings back to the shore into the grit chamber; pump the drill cuttings in the grit chamber into the mixing tank, and adjust the liquid-solid ratio in the mixing tank to be 6:1 by weight percentage; The mixed slurry in the mixed slurry tank is pumped into the first vibrating screen for screening, wherein the concentration of the oversize is maintained at 60% in weight percentage, and the mesh of the vibrating screen is 150 mesh; the first vibrating The undersize of the sieve freely falls into the filter dryer to filter dry, and the solid phase after the filter is sent to the screw conveyor to be transported to the salt dust box. The filter screen mesh gap of the filter dryer is 1.0mm; The undersize of a vibrating screen is combined with the overflow of the filter dryer and sent to the second vibrating screen; the oversize of the second vibrating screen falls into the screw conveyor and is transported to the salt dust box, and the undersize...

Embodiment 3

[0024]Inject the oil-based drilling cuttings back to the shore into the grit chamber; pump the drill cuttings in the grit chamber into the mixing tank, and adjust the liquid-solid ratio in the mixing tank to be 8:1 by weight percentage; The mixed slurry in the mixing tank is pumped into the first vibrating screen for screening, wherein the concentration of the oversize is kept at 20% in weight percentage, and the mesh of the vibrating screen is 80 mesh; the first vibrating The undersize of the sieve freely falls into the filter dryer to filter dry, and the dried solid phase is sent to the screw conveyor to be transported to the salt dust box. The filter screen mesh gap of the filter dryer is 0.4mm; The undersize of a vibrating screen is combined with the overflow of the filter dryer and sent to the second vibrating screen; the oversize of the second vibrating screen falls into the screw conveyor and is transported to the salt dust box, and the undersize is Pumped into the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com