Tomato harvesting device

A technology for tomato and conveying mechanism, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of tomato quality decline, reduced tomato strength, easy to break, etc. Effects of harvesting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

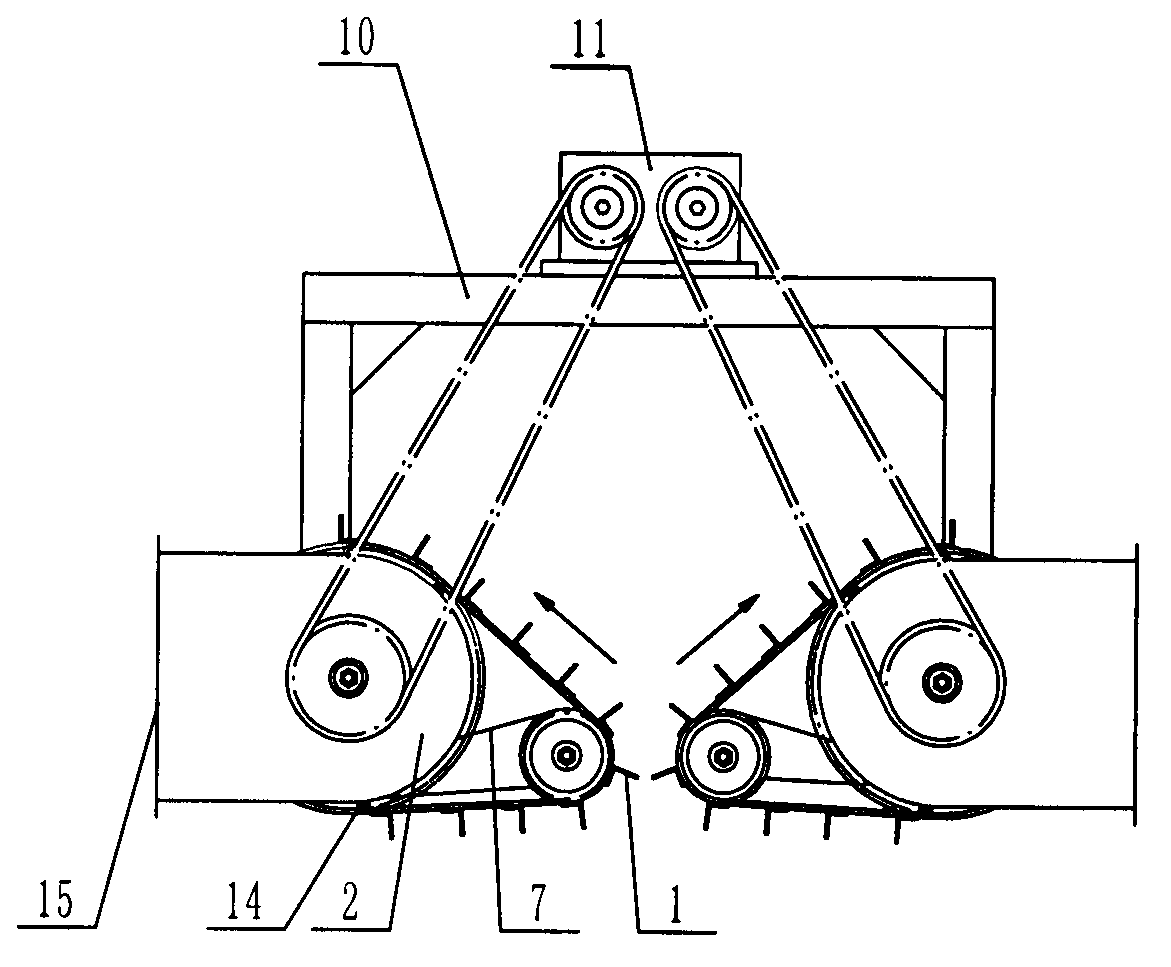

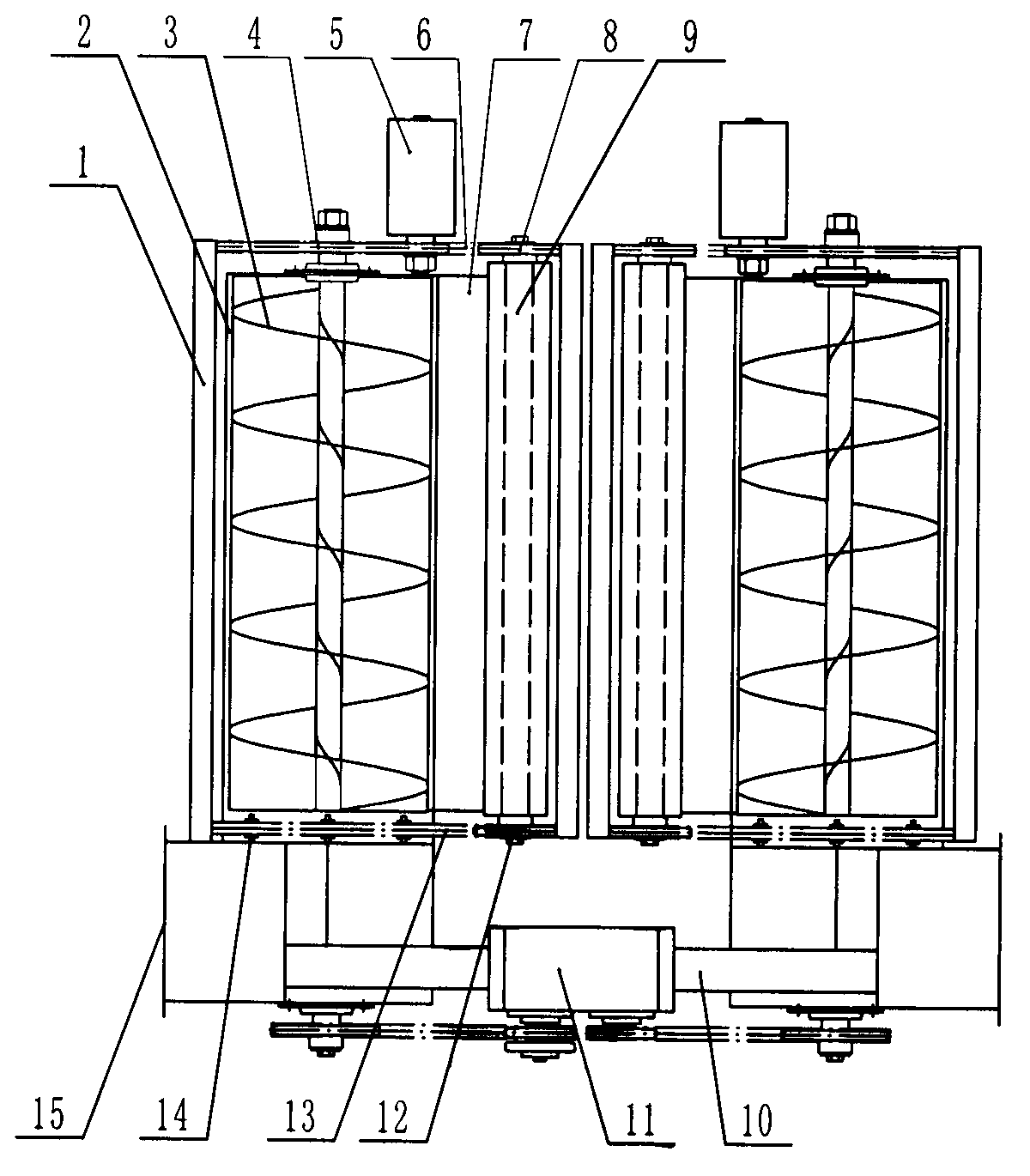

[0014] refer to figure 1 , figure 2 , is an embodiment of a tomato harvesting device, including a transmission system (11), a frame (10), and a picking conveying mechanism, and is characterized in that a tomato harvesting device is provided with two structurally identical left and right sides. Picking and conveying mechanism, two picking and conveying mechanisms are arranged side by side opposite to the front side of frame (10), transmission system is established (11) and is located on the frame (10), and described picking and conveying mechanism is made of picking plate (1 ), front side picking chain (6), rear side picking chain (13), conveying hinged dragon (3), hinged dragon sprocket (4), front small sprocket (8), rear small sprocket (12) , sprocket shaft (9), seedling picking wheel (5), housing (2), roller (14), outlet (15) and sliding plate (7), the above-mentioned picking plate (1) is horizontally arranged on the front side picking plate On the chain (6) and the rear ...

Embodiment 2

[0016] The difference between the present embodiment and embodiment 1 is that the picking plate (1) is a round stick.

Embodiment 3

[0018] The difference between the present embodiment and embodiment 1 is that the described seedling picking wheel (5) is conical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com