Horizontal high-pressure main stop valve disassembling and assembling tool

A main steam valve, high pressure technology, applied in the direction of manufacturing tools, metal processing, transportation and packaging, can solve the problems of loss, damage to alloy bolts, time-consuming and labor-intensive, etc., to save maintenance costs, avoid disassembly and assembly difficulties, and save maintenance. The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail in conjunction with specific inventions below.

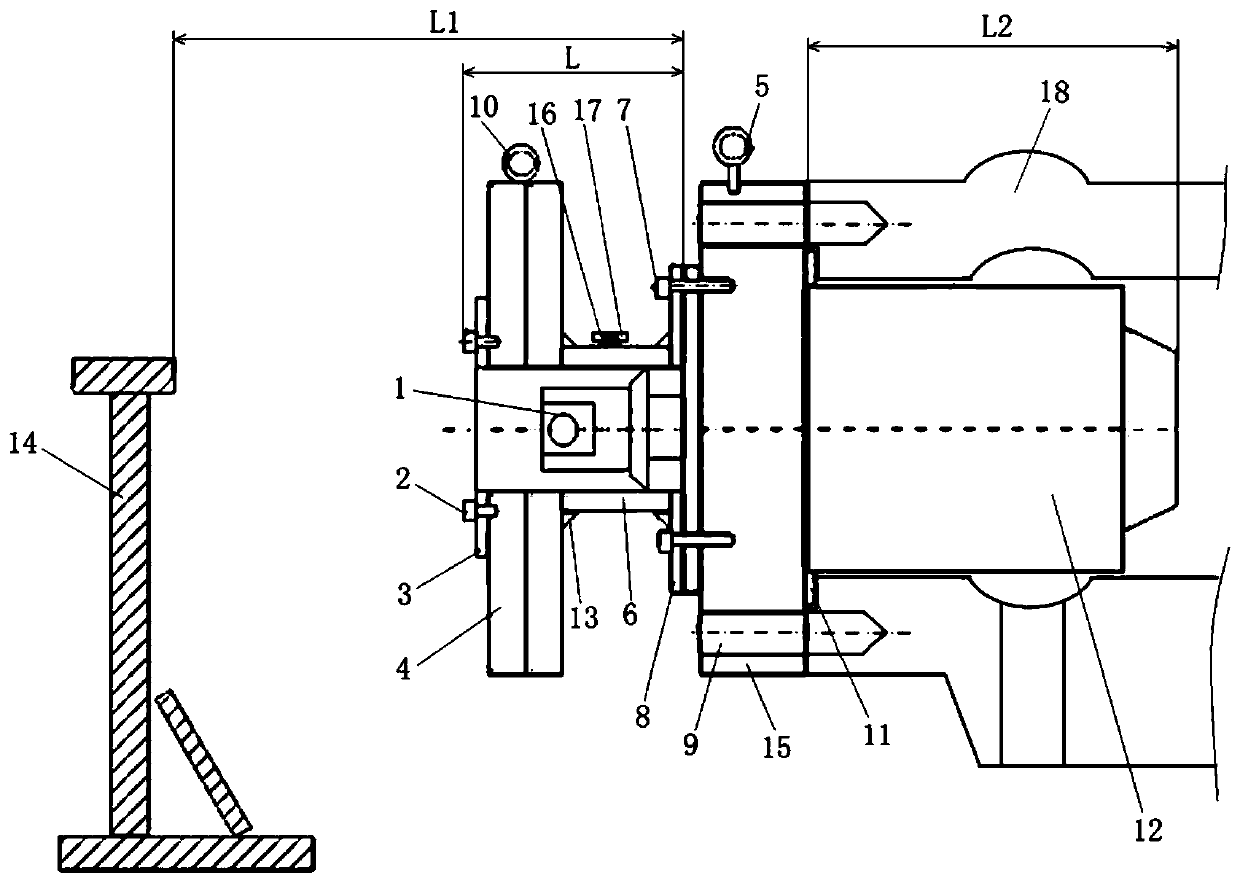

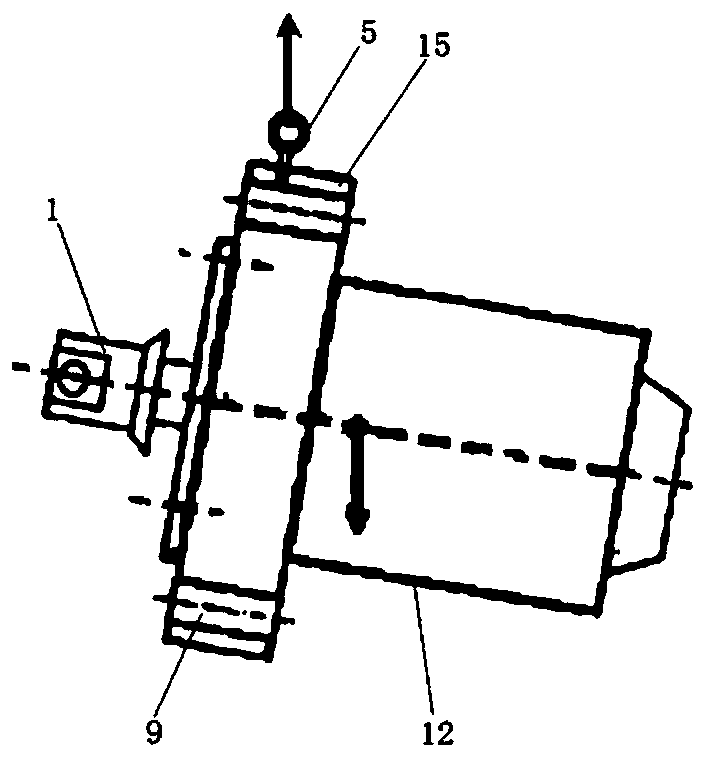

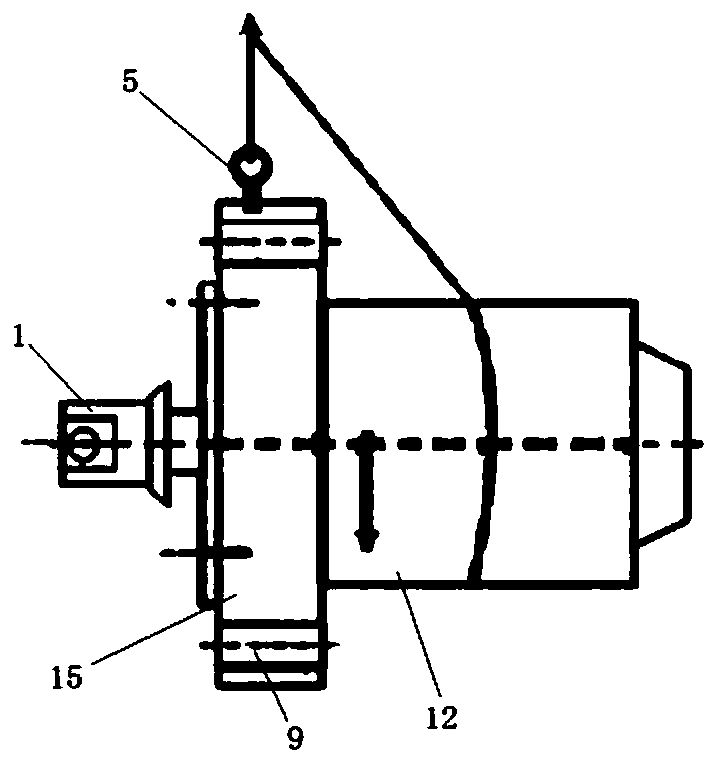

[0027] A horizontal high-pressure main steam valve disassembly tool, combined with figure 1 As shown, it includes a first lifting ring 5 , a balanced lifting structure and a second lifting ring 10 .

[0028] The first suspension ring 5 is fixedly arranged on the top end of the side wall of the main steam valve cover 15 . The second lifting ring 10 is arranged on the top of the balance lifting structure, and cooperates with the first lifting ring 5 to lift the main steam valve.

[0029] The balance hoisting structure is connected to the end of the main steam valve bonnet 15 without the main steam valve core 12, which is used to balance the overall weight of the main steam valve to ensure that the main steam valve core 12 is in a horizontal state during the hoisting process, thereby facilitating Disassemble the main steam valve.

[0030] The balance hoisting stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com