Undisturbed soil scouring test system

A technology of scouring test and undisturbed soil, which is applied in the direction of testing wear resistance, etc., can solve the problems of inconvenient undisturbed soil layering test, inability to realize high-speed water scouring, and inability to obtain soil sample scouring rate, so as to improve test accuracy, Improve the accuracy of test data and test efficiency, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

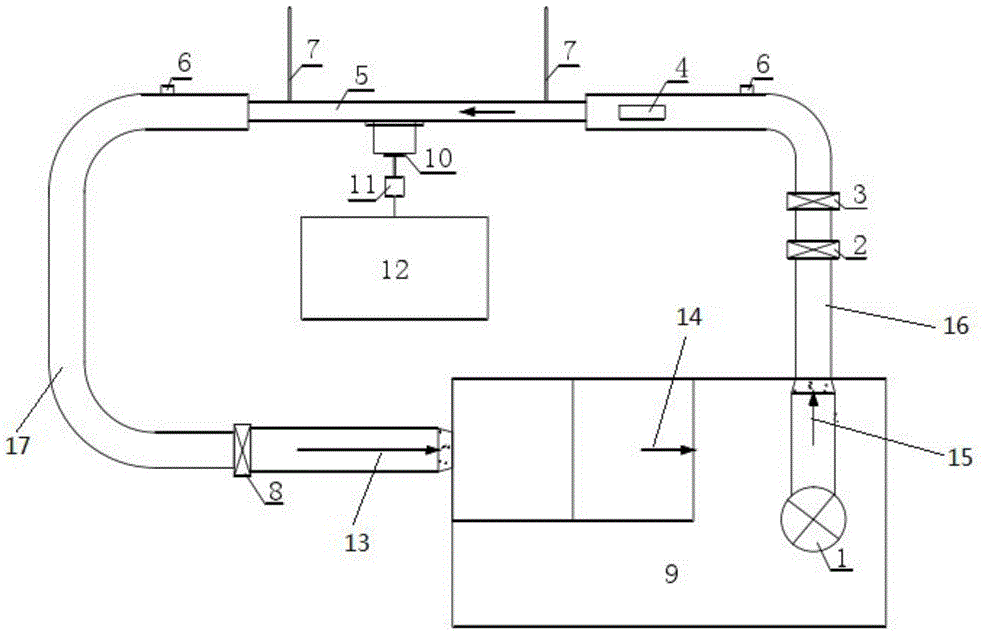

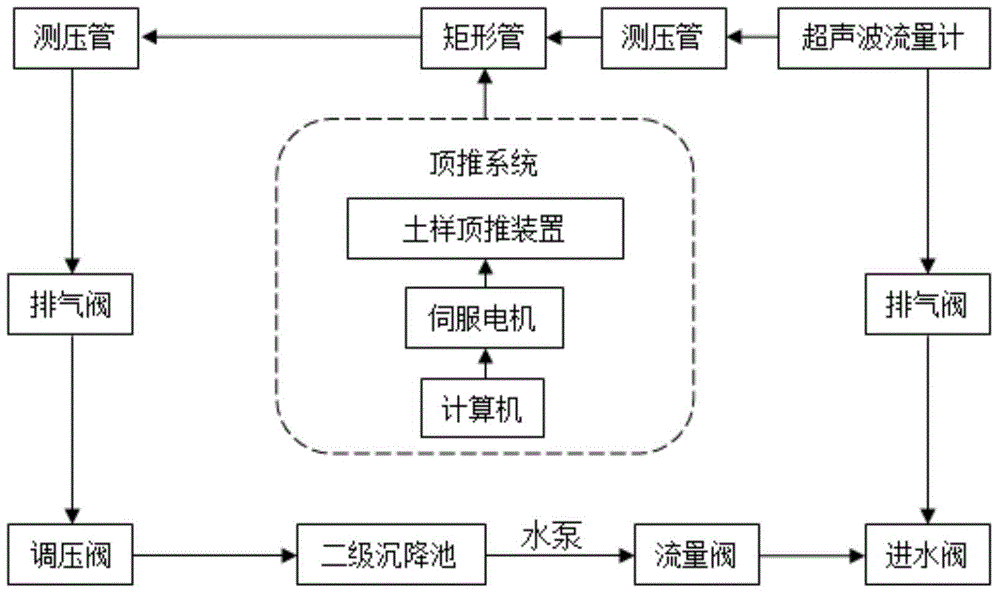

[0052] Such as figure 1 , 2 The undisturbed soil scouring test system shown includes water pump 1, water inlet pipe 16, flow valve 2, water inlet valve 3, ultrasonic flowmeter 4, rectangular pipe 5, water outlet pipe 17, exhaust valve 6, and pressure measuring pipe 7 , jacking system, pressure regulating valve 8 and secondary settling tank 9;

[0053] The water inlet of the water inlet pipe 16 is connected with the water pump 1, the water outlet of the water inlet pipe 16 is connected with the water inlet of the rectangular pipe 5, the water outlet of the rectangular pipe 5 is connected with the water inlet of the water outlet pipe 17, and the water outlet of the water outlet pipe 17 Connect with secondary settling tank 9;

[0054] The flow valve 2 is arranged at the water inlet end of the water inlet pipe 16, the water inlet valve 3 is arranged on the water inlet pipe 16, and is located downstream of the flow valve 2, and the ultrasonic flowmeter 4 is arranged at the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com