Harmless disposal system for refuse and method for refuse disposal by harmless disposal system

A technology for harmless treatment and garbage, which is applied in the direction of combustion method, combustion product treatment, liquefaction, etc. It can solve the problems of insufficient and reasonable utilization of energy, serious smog in surrounding areas, and aggravated greenhouse effect, so as to reduce smoke emission Effects of heat loss, cost reduction, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

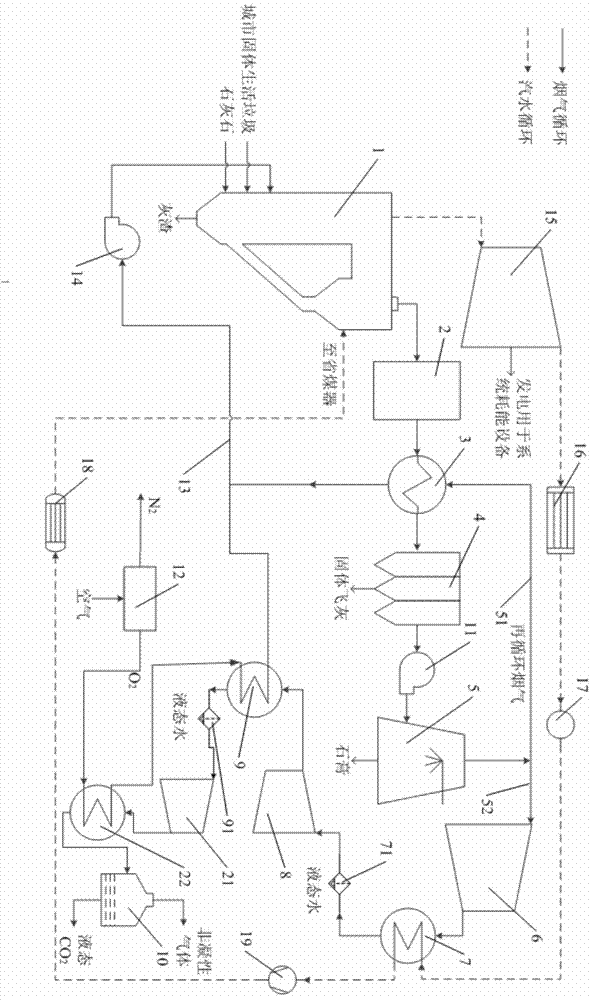

[0044] like figure 1 As shown, a garbage harmless treatment system, the treatment system includes a circulating fluidized bed boiler 1, a denitrification device 2, a gas-gas heat exchanger 3, a dust collector 4, a desulfurization device 5, a first A compressor 6, a first condenser 7, a first liquid water collector 71, a second compressor 8, a second condenser 9, a second liquid water collector 91, a third compressor 21, and a third condenser 22 and gas-liquid separator 10;

[0045] The denitrification device 2 communicates with the hot blast inlet of the gas-gas heat exchanger 3; the dust remover 4 communicates with the hot blast outlet of the gas-gas heat exchanger 3; A booster fan 11 is provided on the pipeline.

[0046] The outlet of the desulfurization device 5 is also in communication with the cold air inlet of the gas-gas heat exchanger 3; the output pipeline at the outlet of the desulfurization device 5 includes a first branch pipeline 52 and a second branch pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com