Patents

Literature

79results about How to "Strong ion exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

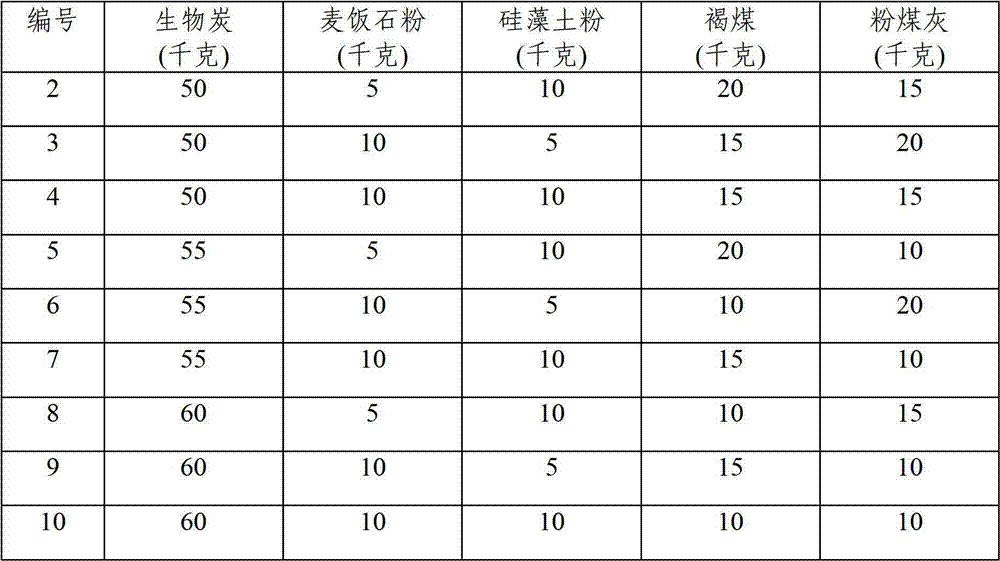

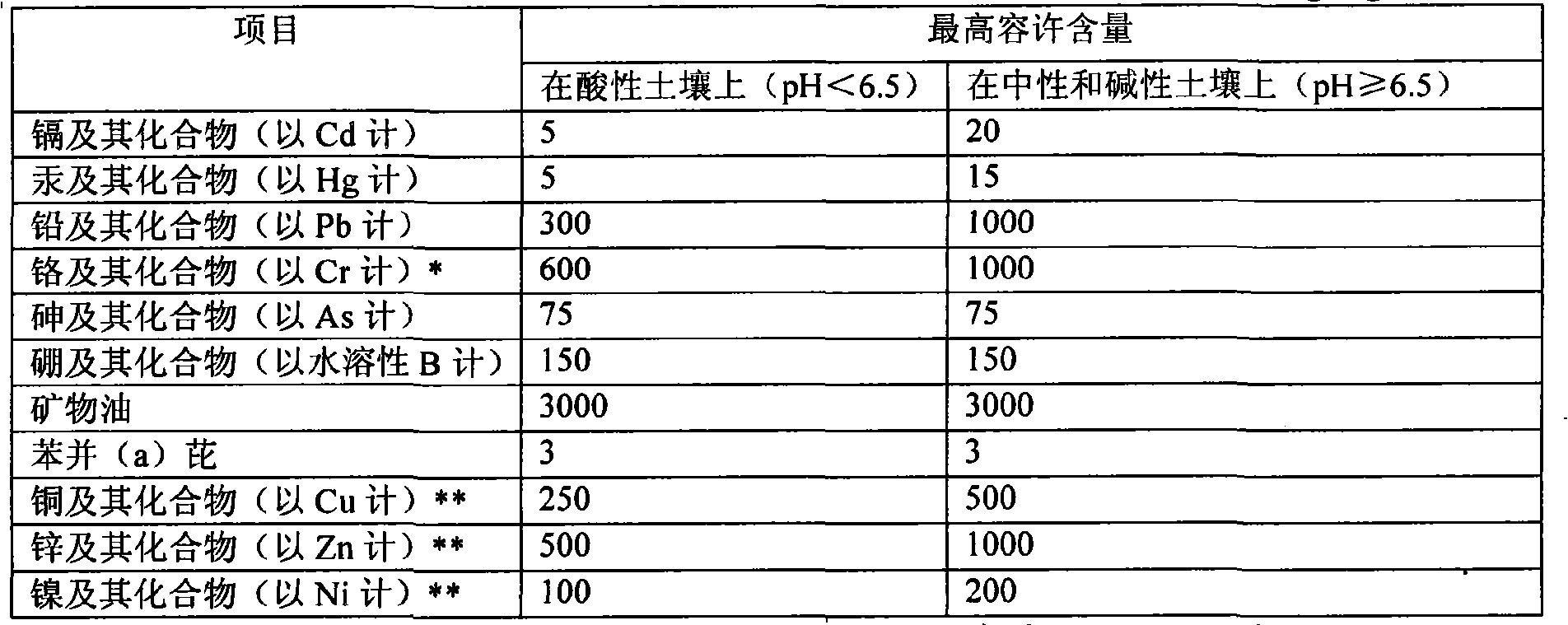

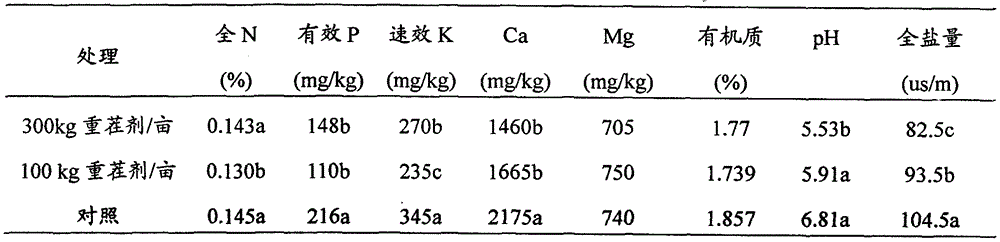

Biochar mixing type protected horticultural vegetable field soil heavy metal passivant and preparation method thereof

InactiveCN102807872ASimple processNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil heavy metalsBiochar

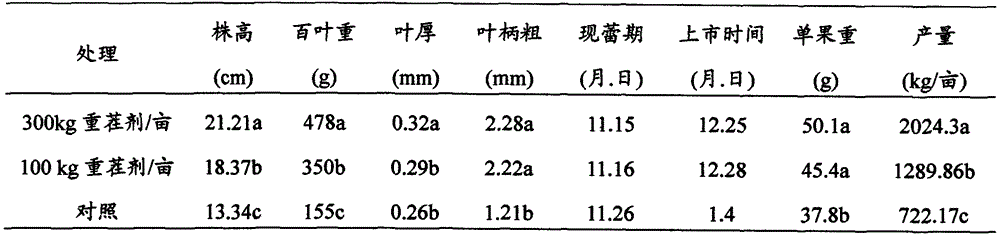

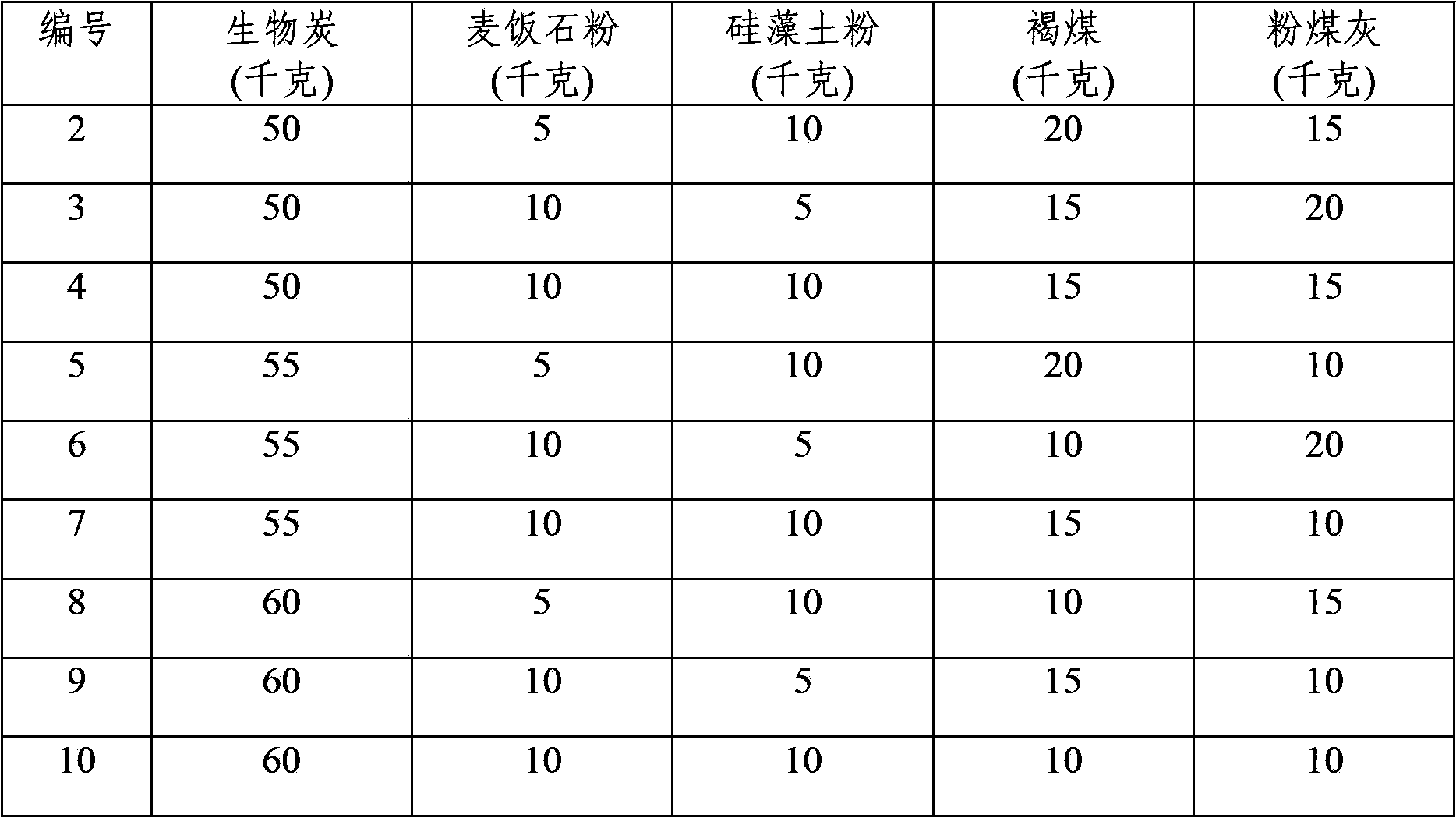

The invention relates to a soil improvement technology and an environment protection technology and particularly discloses a biochar mixing type protected horticultural vegetable field soil heavy metal passivant and a preparation method thereof. The soil heavy metal passivant comprises the following components in percentage by weight: 50 to 60 percent of biochar, 5 to 10 percent of medical stone powder, 5 to 10 percent of diatomite powder, 10 to 20 percent of lignite and 10 to 20 percent of coal ash. The preparation method for the soil heavy metal passivant comprises the following steps of: mixing the medical stone powder which is screened by an 80-mesh sieve, the diatomite powder which is screened by an 80-mesh sieve, the lignite, and the coal ash which is screened by an 80-mesh sieve, uniformly stirring, mixing with biochar which is screened by a 20-mesh sieve, fully stirring, and mixing uniformly to prepare the soil heavy metal passivant. The soil heavy metal passivant is easy to prepare; and the effects of passivating the protected horticultural vegetable field soil heavy metal, and reducing the content of recyclable heavy metal of plant in soil can be achieved under the synergistic effects of all components.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

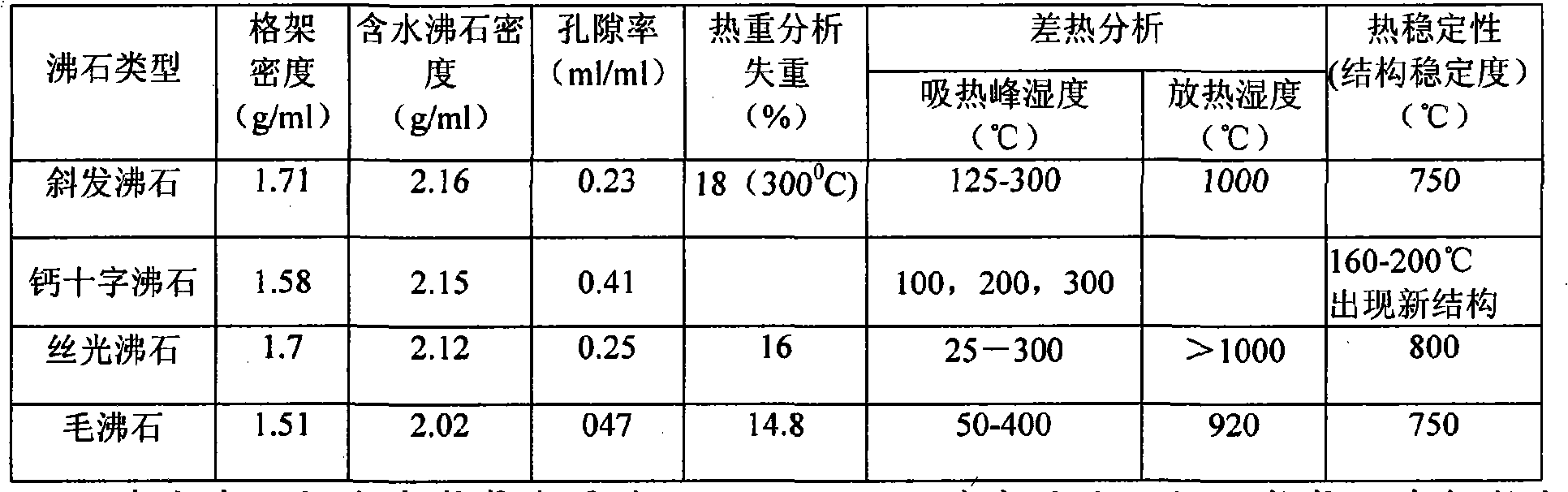

Mixing soil conditioner and its preparation method

InactiveCN101240172ASimple processEasy to implementOrganic fertilisersSoil conditioning compositionsDry weightPhosphogypsum

The invention relates to a soil modifier, specifically, relating to a mixed soil modifier with dejecta of domestic animal and poultry and phosphogypsum as main raw materials and preparation method thereof. The soil modifier comprises dejecta of domestic animal and poultry 50% to 65%, phosphogypsum 25% to 45%, and zeolite 5% to 10% according to dry weight percent, comprising steps of: mixing said raw materials in proportion, paying them on ground, drying them in shade, then processing air-dry treatment, to obtain finished product; for manufactory production, drying mixture after air-dry treatment, agitating it evenly, selecting it by sieve, packaging it to obtain the finished product. The preparation of the invention is simple with low finished product cost, adaptable to saline soil modification, and modification and repair of magnesite dust-polluted soil.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

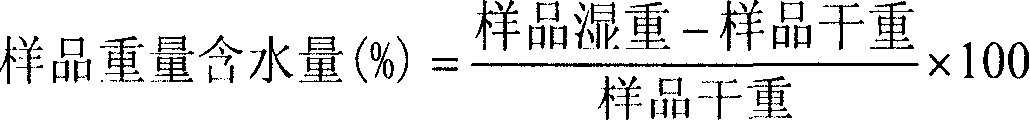

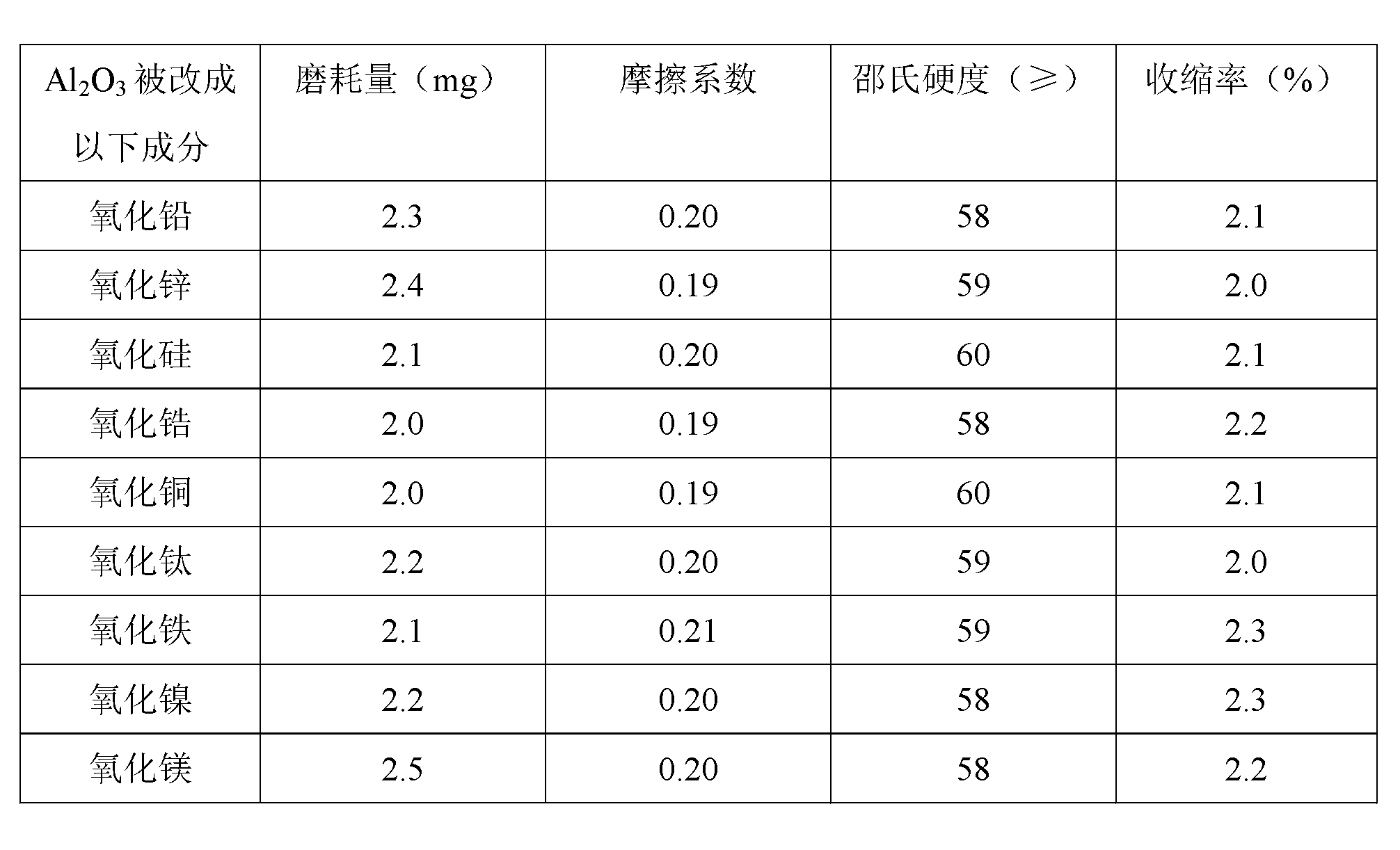

Method for preparing ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material

The invention discloses a method for preparing an ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The method comprises the steps of 1) proportioning materials, i.e. mixing polytetrafluoroethylene, ultrafine zeolite powder, a filler I and a filler II according to the ratio; 2) uniformly mixing the mixture proportioned and then carrying out cold press forming under the pressure of 20-40 Mpa; 3) putting the formed object obtained in the step 2) into a high temperature sintering furnace, heating to 330-380 DEG C with the speed of 30-100 DEG C / hour and preserving heat for 0.5-2 hours; and 4) naturally cooling sintering products obtained in the step 3) to the room temperature to obtain the ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material prepared according to the method has excellent performance, the wear resistance of the composite material is improved upon the premise of not remarkably reducing the matrix friction coefficient of PTFE, and the application range of the composite material is wide.

Owner:ZHEJIANG UNIV

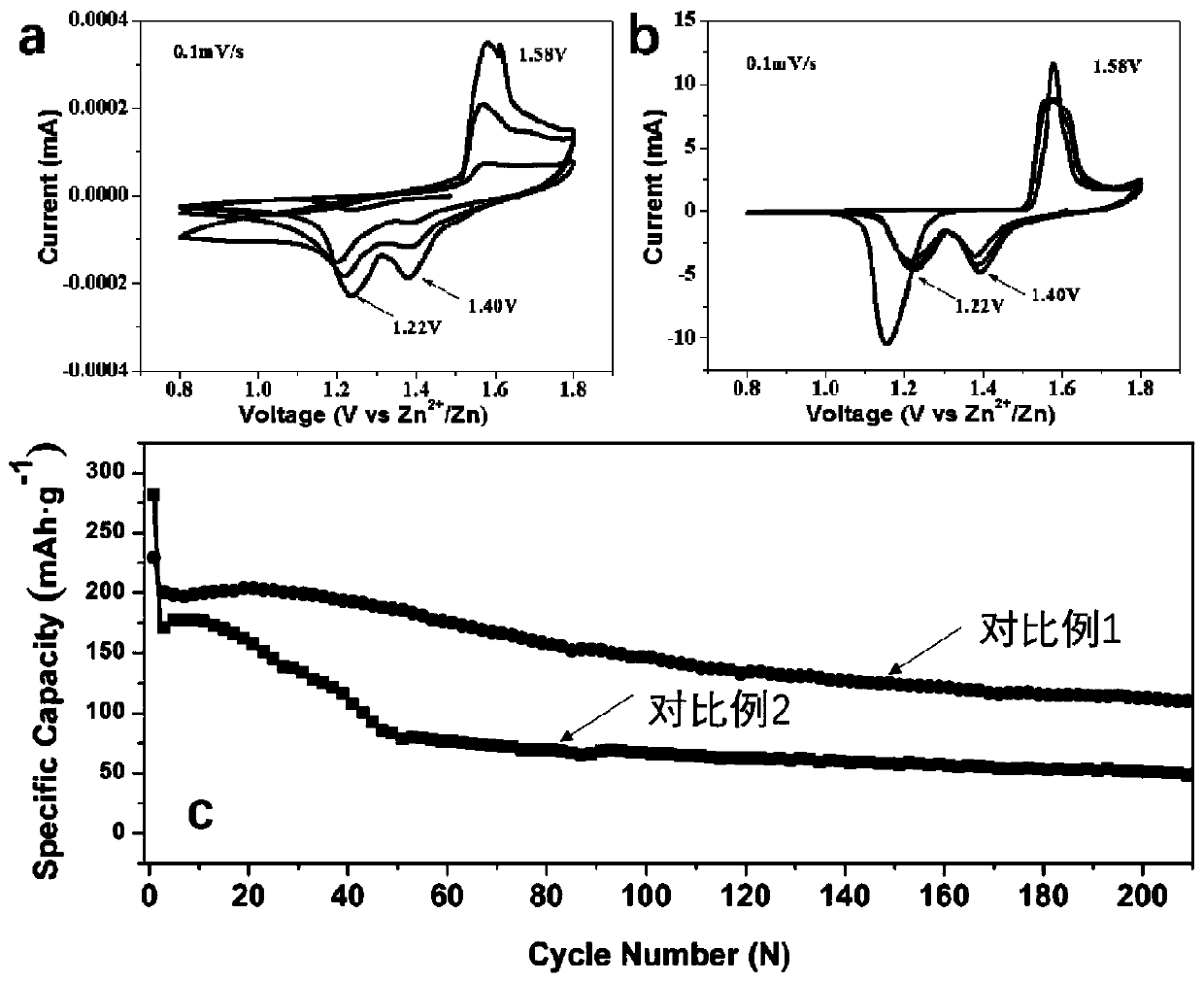

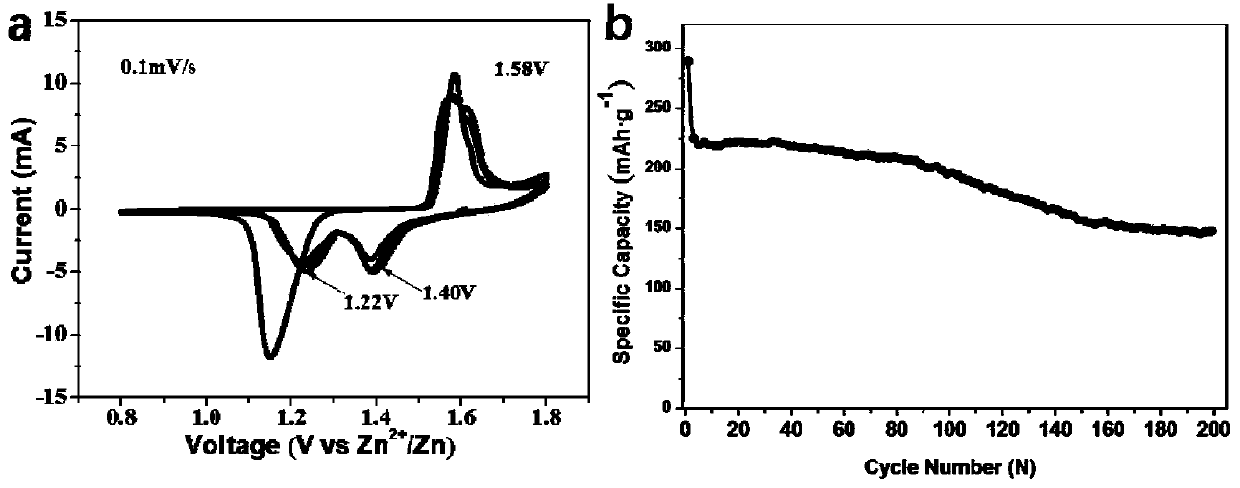

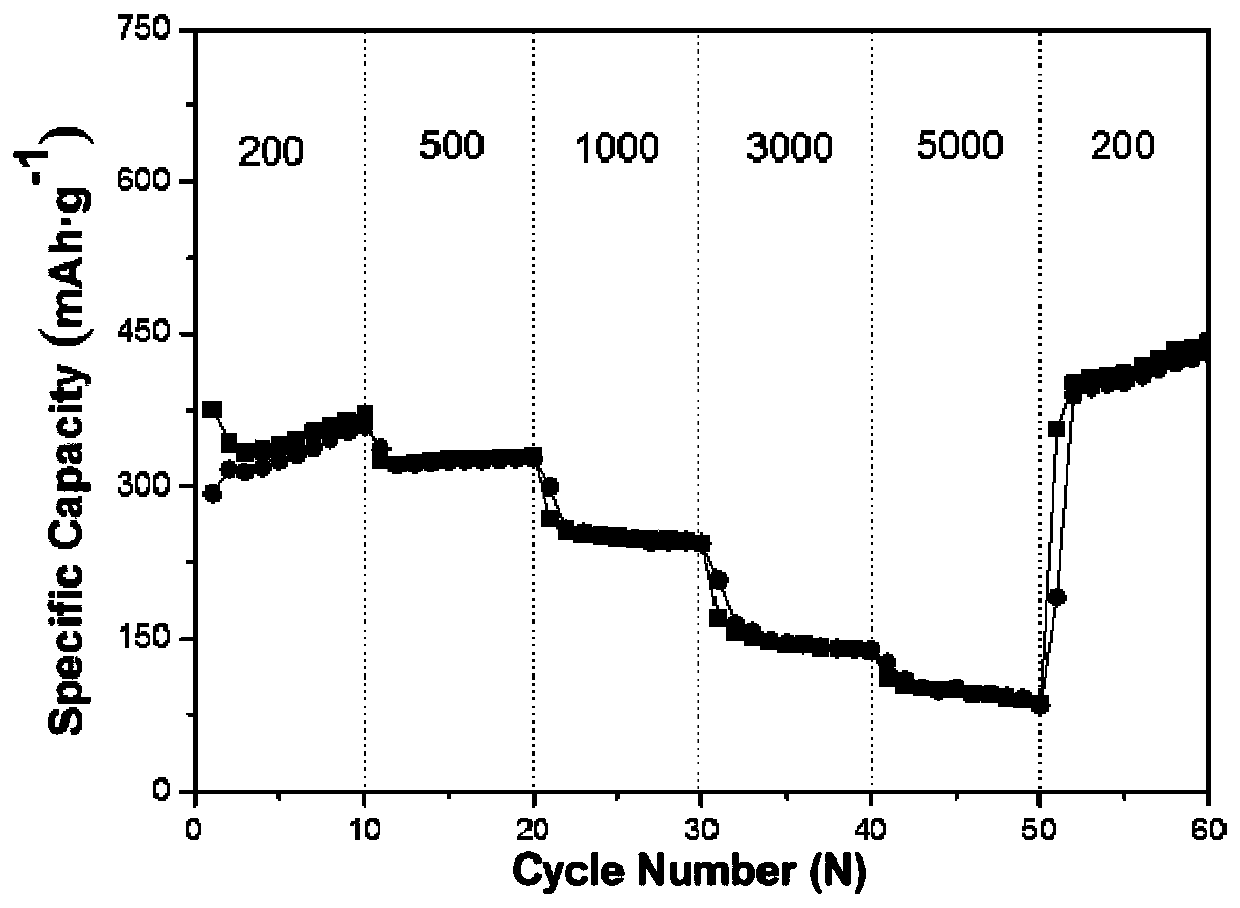

Water-based zinc ion battery colloidal electrolyte, and preparation method and application thereof

ActiveCN109980302AImprove conductivityImprove adsorption capacitySecondary cellsElectrolyte immobilisation/gelificationWater basedHigh energy

The invention discloses water-based zinc ion battery colloidal electrolyte, and a preparation method and an application thereof. The colloidal electrolyte material is formed by adding a clay materialto liquid electrolyte and uniformly mixing the same. The preparation method comprises the following steps: adding the clay material to conventional liquid electrolyte, thoroughly mixing the same understirring, and performing ageing to obtain uniform and stable colloidal electrolyte. The colloidal electrolyte prepared by the preparation method disclosed by the invention has higher ionic conductivity than liquid electrolyte, a colloidal zinc ion battery has excellent performance, good safety, stable performance and higher specific capacity, maintains excellent cycle stability and shelving performance or the like at high and low current densities, and meets the requirements of the water-based zinc ion energy storage technology with high energy density and long life, thereby having a broad application development space.

Owner:CENT SOUTH UNIV

Method for comprehensively utilizing fine coal gasification slag

ActiveCN107857496AHigh activityImprove adsorption capacityOther chemical processesSolid waste managementCycloneSlag

The invention discloses a method for preparing an adsorption material from fine coal gasification slag. The method comprises the following steps: 1, taking a proper amount of the fine coal gasification slag, and adding water to prepare a fine coal gasification slag slurry with the solid content being 10-30 wt%; 2, fully stirring the slurry prepared in step 1, performing gravity cyclone separation,collecting the obtained heavy separation product to obtain a silicon-rich composite slurry, and collecting the obtained light separation product to obtain a carbon-rich composite slurry; and 3, carrying out solid-liquid separation and drying on the carbon-rich composite slurry to obtain the carbon-rich adsorption material, and further preparing other products from the remaining silicon-rich composite slurry. The method realizes the high-added value recycling of the fine coal gasification slag.

Owner:鄂尔多斯市慧恒科技有限责任公司

Method for preparing composite meso-porous material from coarse coal gasification slag, and meso-porous material prepared therethrough

ActiveCN107855104ARealize the comprehensive utilization of all componentsImprove physicsOther chemical processesAlkali metal oxides/hydroxidesSlagAcid dissolution

The invention discloses a method for preparing a composite meso-porous material from coarse coal gasification slag. The method comprises the following steps: 1, taking the coarse coal gasification slag, mixing the coarse coal gasification slag with a proper amount of an acid solution to obtain a slurry, and performing an acid dissolution reaction; and 2, carrying out solid-liquid separation on a material obtained after the acid dissolution reaction, and performing washing and drying to obtain the product. The invention also discloses the composite meso-porous material prepared through the method. The carbon / silicon composite meso-porous material is obtained through controlled dissolution under mild conditions by using the high activity of silicon aluminum calcium iron in the coarse coal gasification slag. The material has the advantages of good physical and chemical adsorption performances, good ion exchange performance, simple preparation process, low cost, realization of further preparation of a water purifier from dissolved metal ions, realization of the comprehensive utilization of all components in the coal gasification slag, and realization of changing wastes into valuables.

Owner:鄂尔多斯市慧恒科技有限责任公司

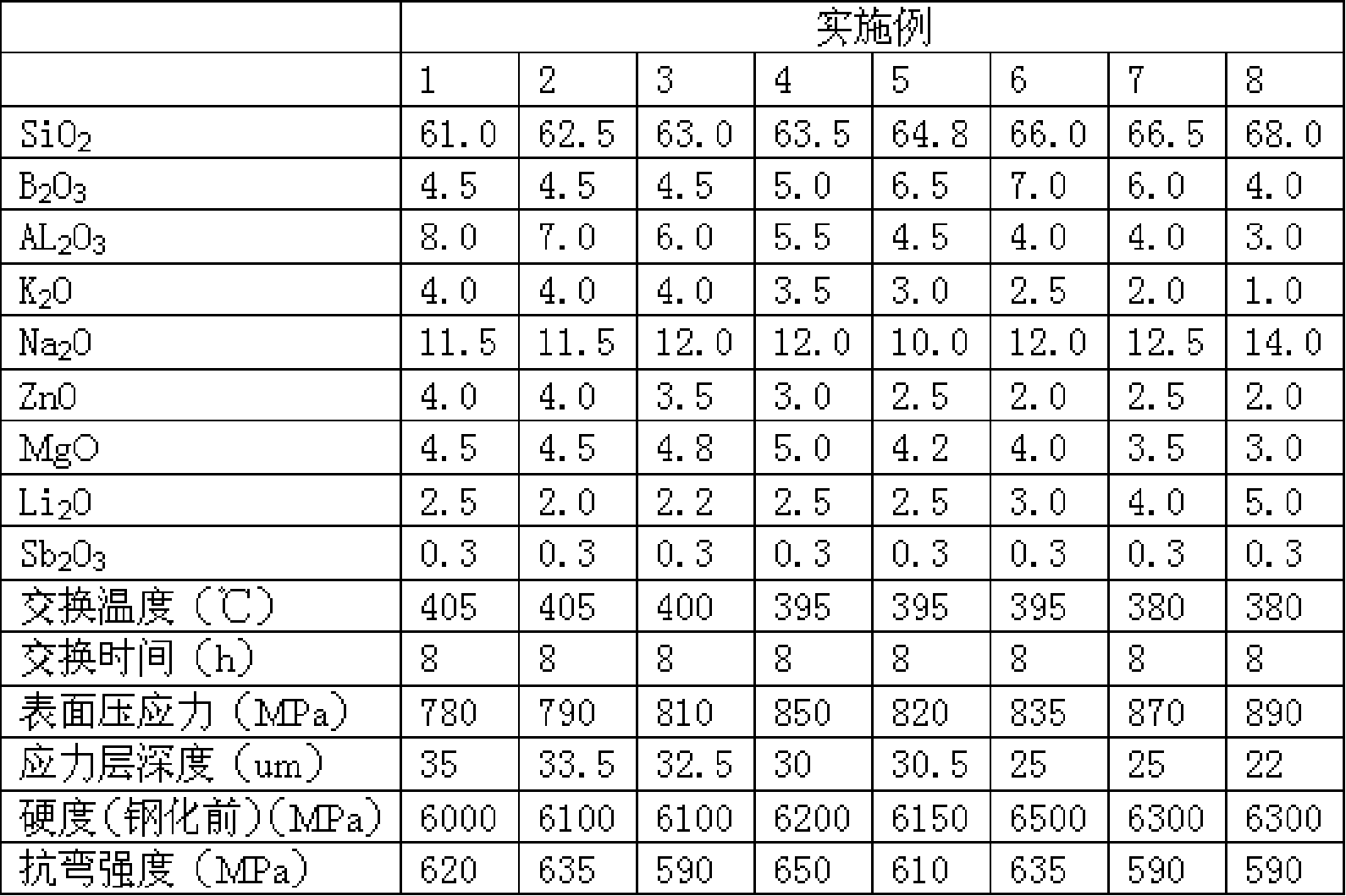

Glass for chemical tempering

ActiveCN101172771AImprove crystallization abilityEasy to produce by down-draw methodDevitrificationHardness

The invention relates to glass used for chemical strengthening, the weight percentage component of the glass comprises 60 to 70 percent of SiO2, 3 to 8 percent of Al2O3, 4 to 8 percent of B2O3, 10 to 15 percent of Na2O, 3 to 8 percent of MgO, 1 to 5 percent of ZnO, 1 to 5 percent of Li2O, 1 to 5 percent of K2O. The melting temperature of the invention is lower than 1450 DEG C, the surface compressive stress is higher than 750 MPa, and the liquidus temperature is lower than 900 DEG C. The invention has good devitrification performance and is easy to be produced through down-draw process. The transformation temperature of the invention is lower than 500 DEG C, thereby being applicable for the low-temperature ion transformation. The invention has good ion transformation performance, the ion transformation layer of the chemical strengthened glass obtained by transformation in short time is 20 to 35 microns, the buckling strength is 550 to 650 MPa, and the hardness is 6000 to 7000 MPa, so the invention can be widely used in windows such as a watchcase and a cell phone faceplate.

Owner:CDGM OPTICAL GLASS

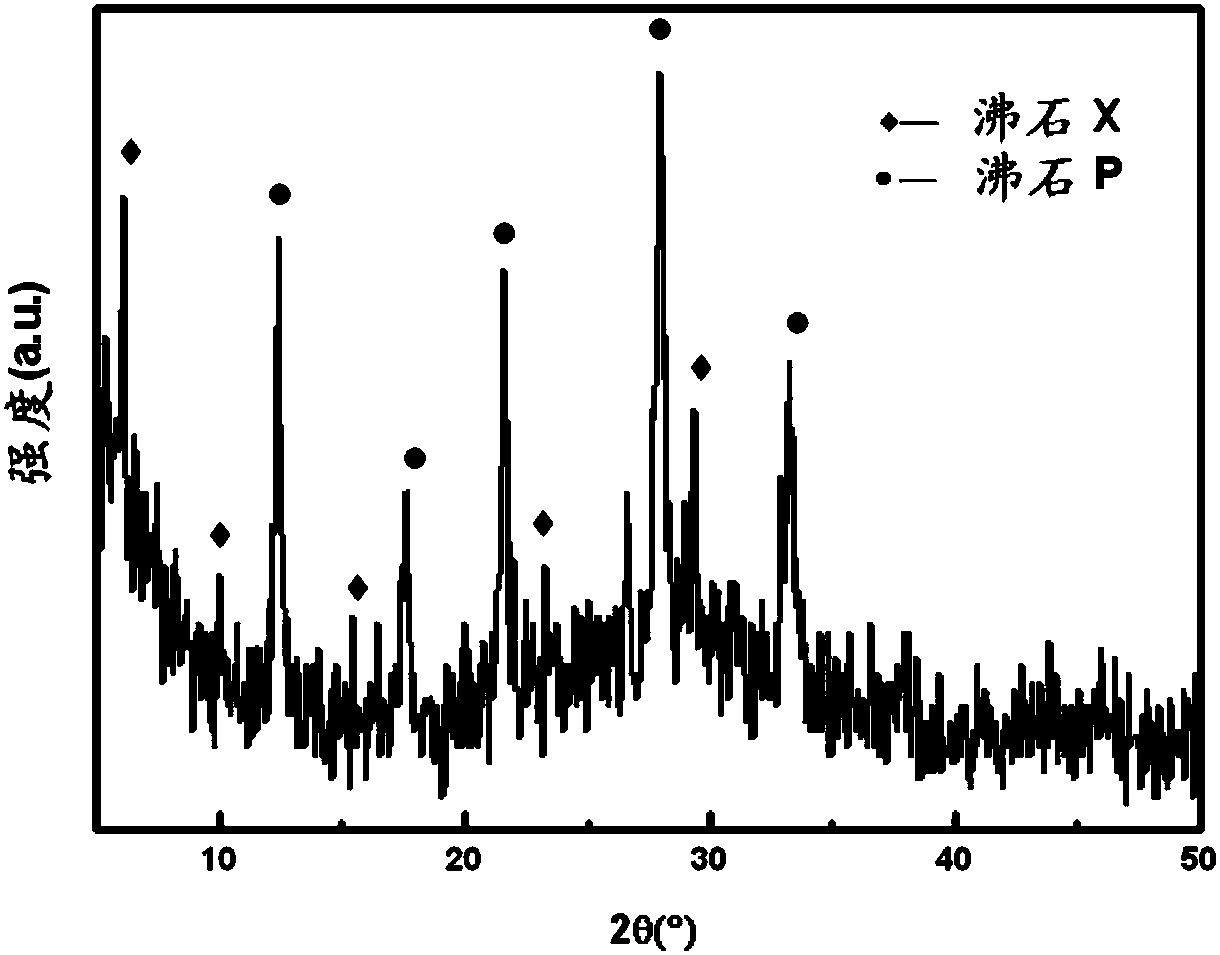

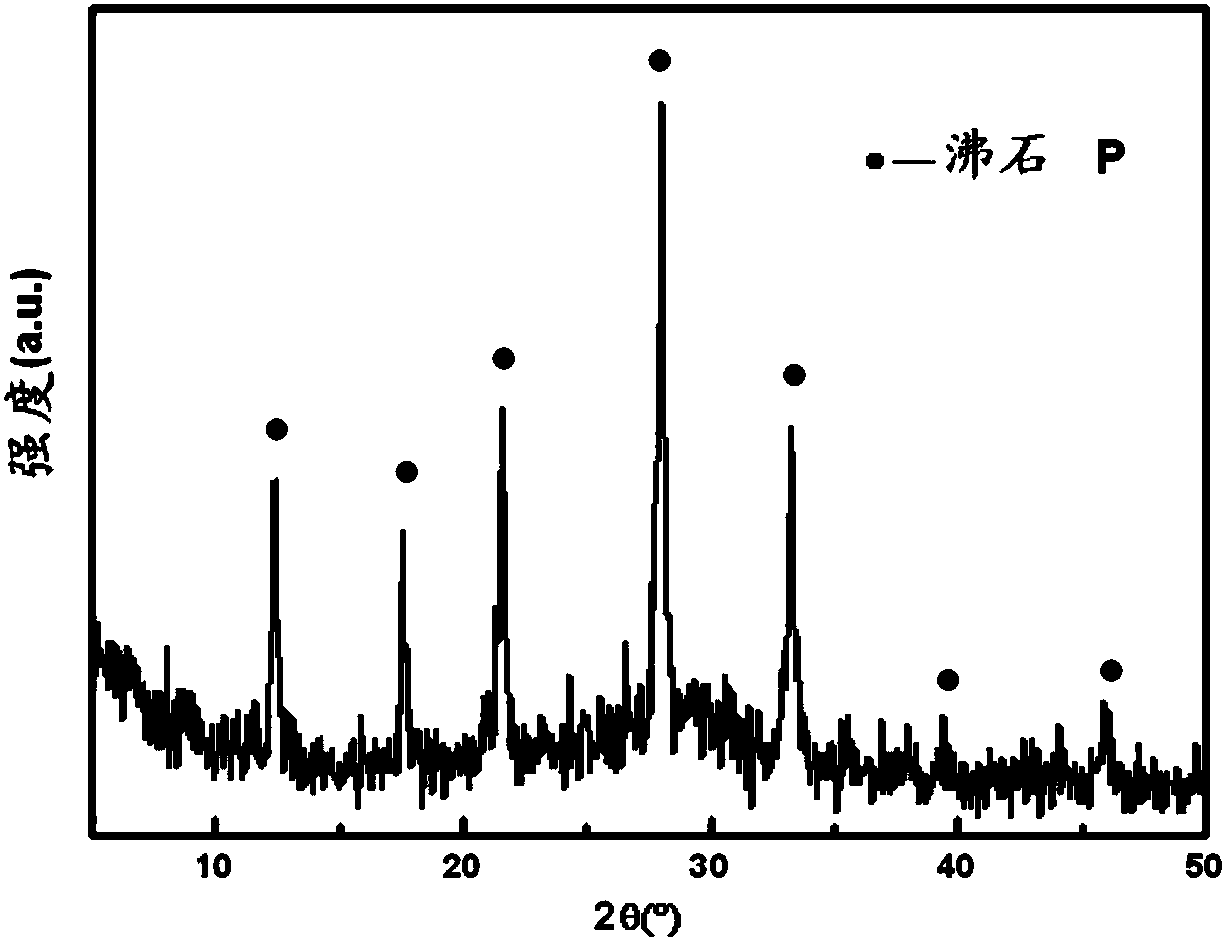

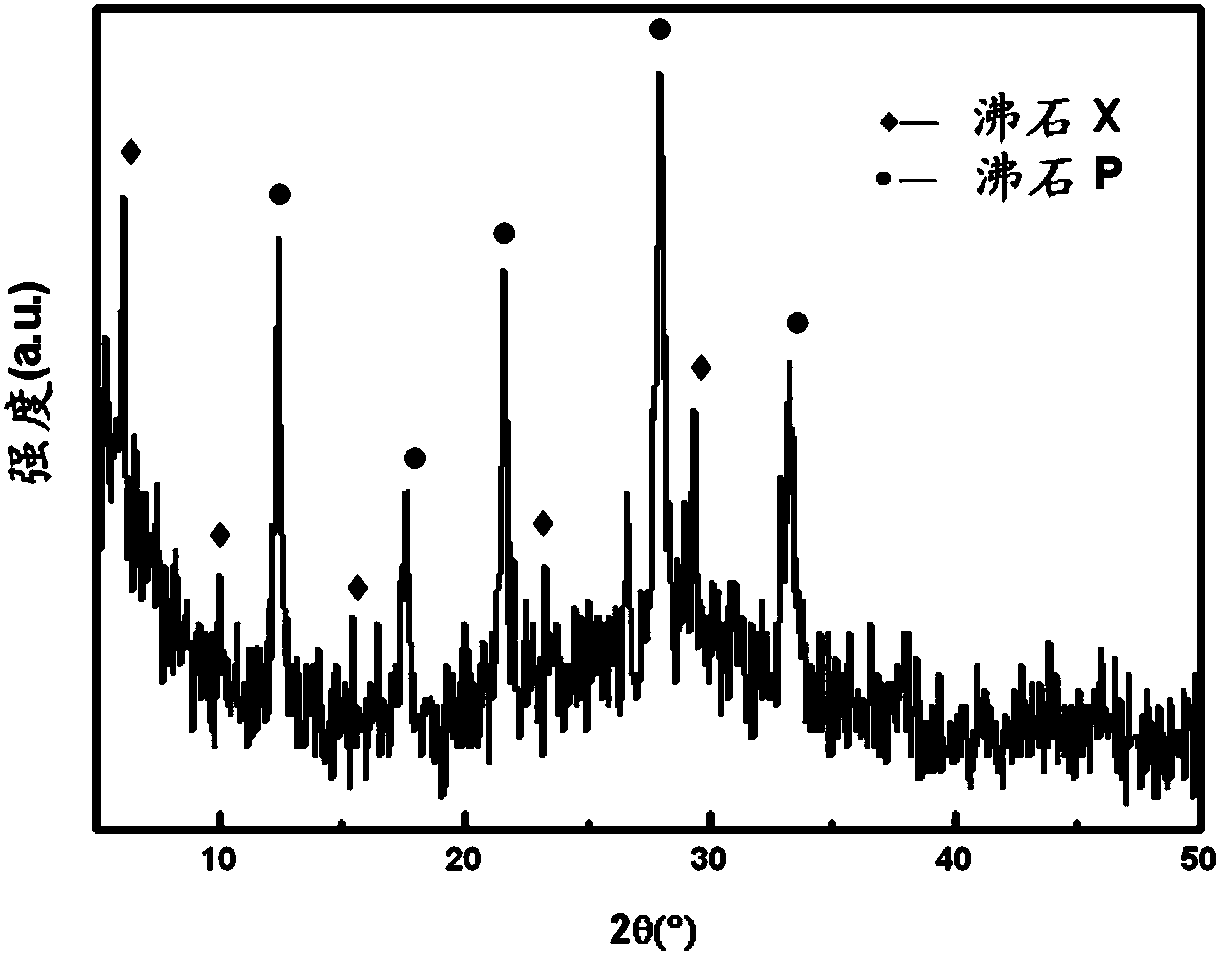

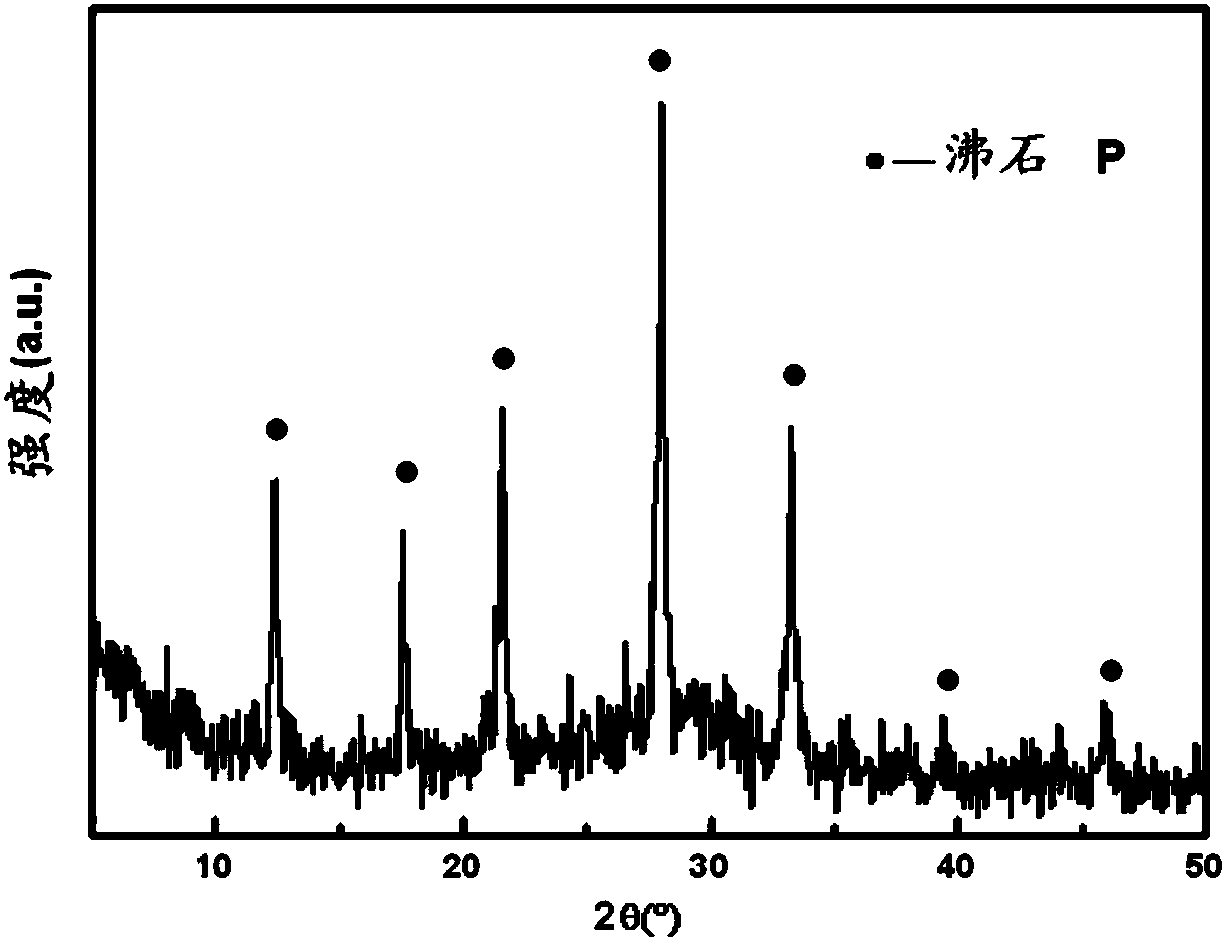

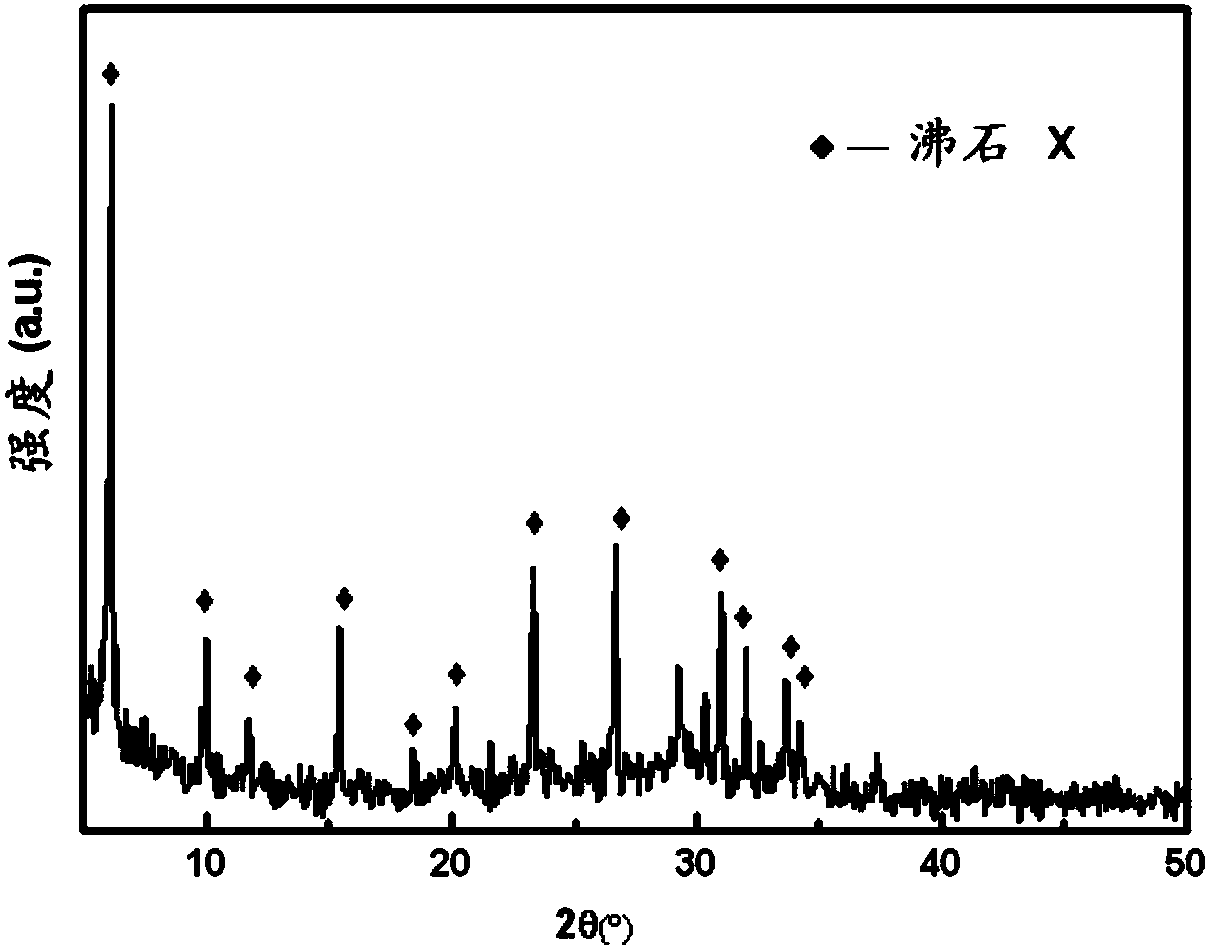

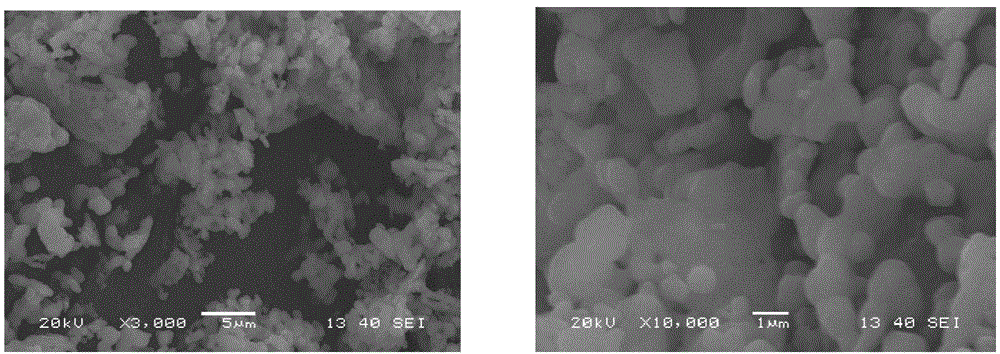

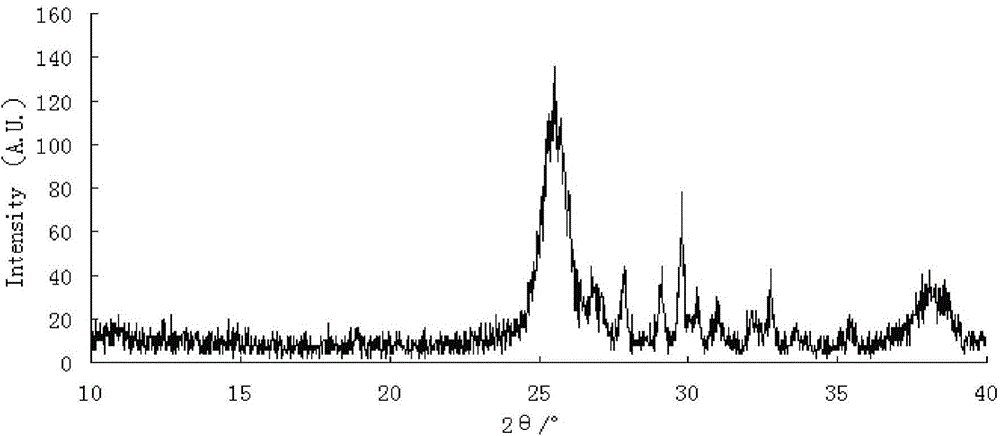

Method for synthesizing zeolite from fine coal gasification slag, and zeolite material prepared therethrough

The invention discloses a method for synthesizing zeolite from fine coal gasification slag, and a zeolite material prepared therethrough. The method comprises the following steps: 1, taking a proper amount of the fine coal gasification slag, and adding water to prepare a fine coal gasification slag slurry with the solid content being 10-30 wt%; 2, fully stirring the slurry prepared in step 1, performing gravity cyclone separation, and collecting the obtained heavy separation product to obtain a silicon-rich composite slurry, wherein the carbon content of a solid phase in the silicon-rich composite slurry is less than 10 wt%; 3, adjusting the solid content of the silicon-rich composite slurry to 5-10 wt%, adding NaOH to make the concentration of the NaOH in the slurry reach 4-10 wt%, and stirring and reacting the slurry at 40-80 DEG C to obtain a precursor; and 4, transferring the precursor into a reaction kettle, sealing the reaction kettle, performing a hydrothermal synthesis reactionat 100-140 DEG C for 4-10 h, and then carrying out solid-liquid separation, washing and drying to obtain the synthesis product. The iron-supported micro-porous zeolite is obtained through the hydrothermal synthesis of the fine coal gasification slag, so the development of the high-added value product from low-carbon and high-silicon ferroaluminum components in the fine coal gasification slag is realized, and wastes are changed into valuables.

Owner:鄂尔多斯市慧恒科技有限责任公司

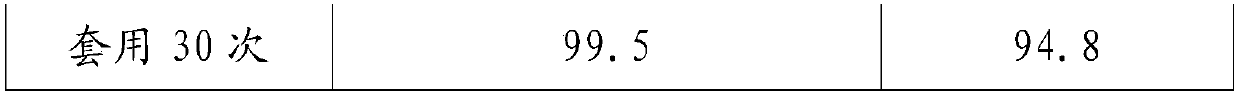

Nutrient soil for pot flowers and preparation method of nutrient soil

InactiveCN107417363ALong-acting slow-release effect is obviousIncrease porositySuperphosphatesGrowth substratesFertilizerNutrient

The invention discloses nutrient soil for pot flowers and a preparation method of the nutrient soil. The nutrient soil comprises the following raw materials: 30-40 parts of garden soil, 9-18 parts of modified perlite, 5-15 parts of an inorganic fertilizer, 3-16 parts of decayed tree leaves, 3-9 parts of straw decayed bacteria, 4-12 parts of bacillus subtilis, 5-12 parts of biogas residues, 2-8 parts of chitosan, 3-5 parts of a preservative, 1-3 parts of a controlled release formulation, 1-4 parts of a trace element mixture and 120-130 parts of water. According to the nutrient soil for pot flowers provided by the invention, by utilizing the adsorption capacity and (fertilizer and water) storage properties of the controlled release formulation and the perlite, the sustained release effect of the nutrient soil is obvious. The nutrient soil provided by the invention does not need to be fertilized within one year, needs to be rehydrated once per month and needs to be kept moisturized.

Owner:合肥慧明瀚生态农业科技有限公司

Long active organic compounded fertilizer and production method

InactiveCN101289348ASolve land occupationSolve secondary pollutionAlkali orthophosphate fertiliserClimate change adaptationResource utilizationPhosphate

The invention relates to a long-acting organic compound fertilizer and a manufacturing method thereof, which belongs to the manure field. By taking sludge in a municipal sewage treatment plant as main raw material, adding zeolite, urea, ammonium diacid phosphate, potassium chloride and sodium silicate, then being stirred and mixed with the urea, the ammonium diacid phosphate and the potassium chloride after sludge compression, zeolite drying, stirring and mixing, natural air drying or kiln drying and grinding, and spraying the sodium silicate so as to granulate, dry, disinfect and sterilize the mixture, a product is then produced. The long-acting organic compound fertilizer and the manufacturing method solve the problem of land occupation of the sludge in the sewage treatment plant and secondary pollution, and realize the harmless disposal and resource utilization of the sludge. The fertilizer ensures that crops has good growth power, high plants, more grains, stronger lodging resistance and obvious stimulation effect and ensures that the quality of agricultural products is improved. Furthermore, the fertilizer can increase the ability of reserving nutrients in soil, can modify acid or saline alkali sandy soil, can improve soil aggregate structure, can keep fertilizer efficiency and resist crop diseases.

Owner:屈智和 +1

Soil improvement agent and preparation method thereof

InactiveCN107033922AReduce pollutionRaise the pHAgriculture tools and machinesOther chemical processesSodium BentonitePotassium sulfate

The invention discloses a soil improvement agent. The soil improvement agent is prepared from the following raw materials in parts by weight: 10-20 parts of bentonite, 5-8 parts of zeolite powder, 13-18 parts of plant straws, 15-25 parts of bean pulp, 8-13 parts of waste tobacco leaf dottle, 10-20 parts of polyacrylamide, 2-3 parts of boric acid, 10-18 parts of humic acid, 4-7 parts of chitosan, 2-3 parts of potassium sulfate and 3-4 parts of a mixed strain. A preparation process of the soil improvement agent is simple, the raw materials are sufficient, and the soil improvement agent is low in cost, has a good improvement effect and is used for preventing and controlling soil acidification and salination, so that the problem that the sustainable utilization of soil is influenced by quality reduction of soil is solved.

Owner:合肥卓畅农业科技有限公司

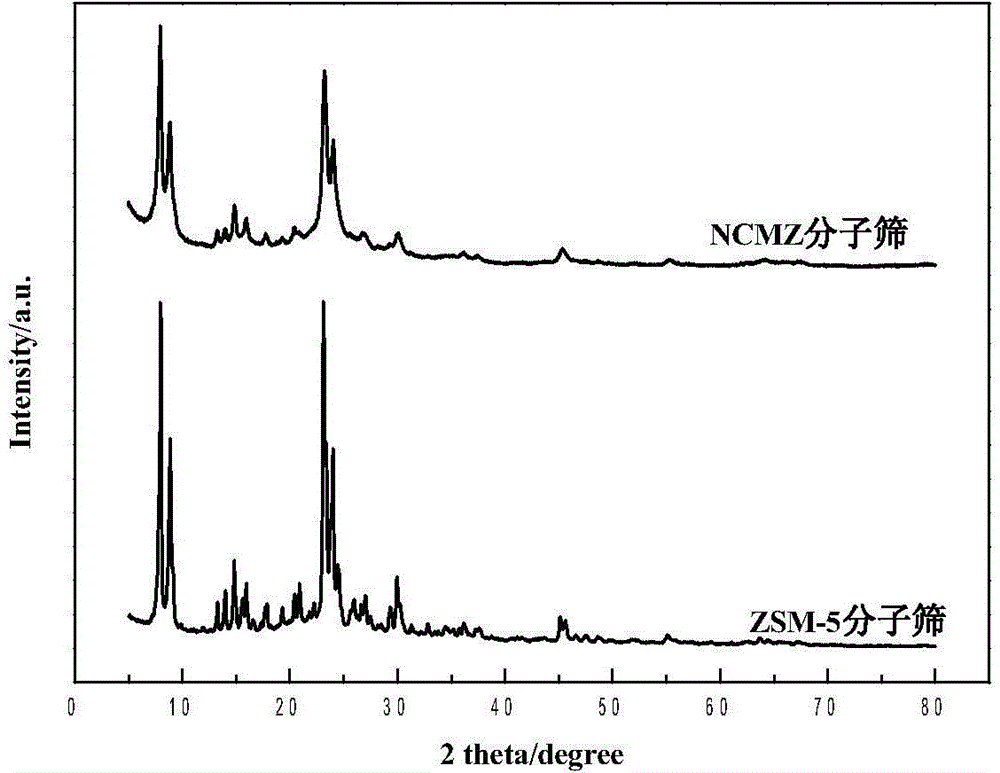

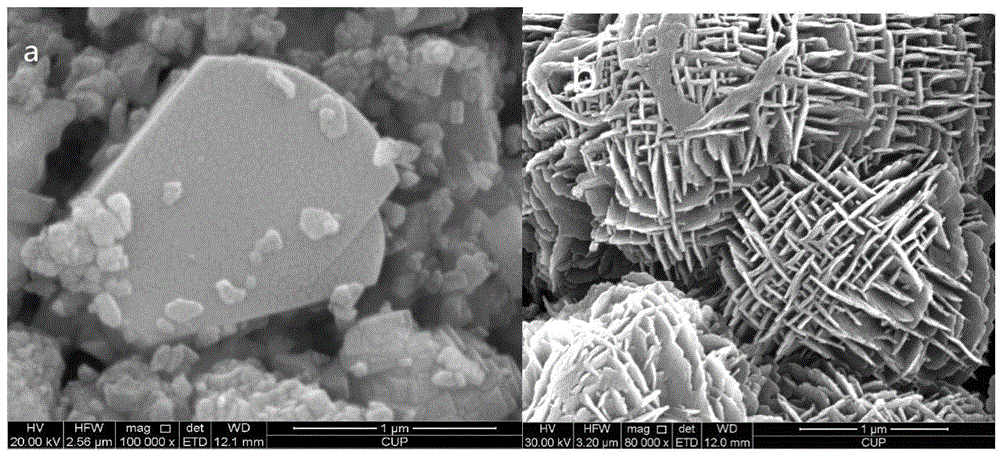

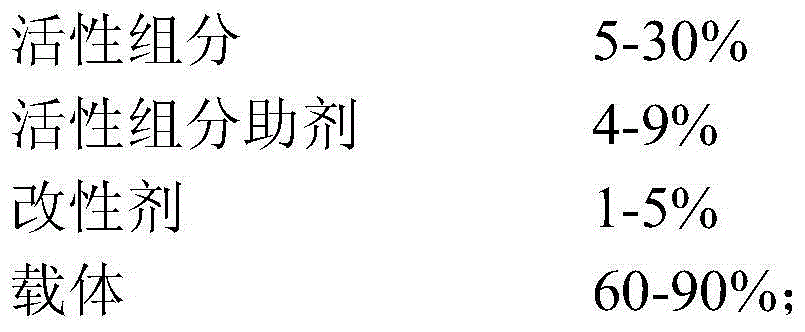

Preparation method of catalytically cracked gasoline hydrodesulfurization catalyst containing nanocrystalline multi-stage duct ZSM-5 molecular sieve

ActiveCN104549524AEfficient removalRegular channel structureOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningHydrodesulfurizationActive component

The invention relates to a preparation method of a catalytically cracked gasoline hydrodesulfurization catalyst containing a nanocrystalline multi-stage duct ZSM-5 molecular sieve. The catalytically cracked gasoline hydrodesulfurization catalyst mainly consists of the following components in percentage by weight: 5-30% of active components, 4-9% of an active component auxiliary, 1-5% of a modifying agent and 60-90% of carriers, wherein the active components comprise at least one of Mo and W metal elements; the active component auxiliary comprise at least one of Co and Ni elements; the modifying agent is one of metals La and Ce, or the compounding of the metal La and Ce; the carriers are composite carriers using aluminum oxide and an NCMZ molecular sieve as main bodies. According to the invention, through the unique framework and duct structure of the NCMZ molecular sieve, the advantages of a micropore ZSM-5 molecular sieve and the advantages of mesoporous materials are combined, so that the reaction efficiency is further improved, and increasing product quality is finally realized. The FCC gasoline hydrodesulfurization catalyst disclosed by the invention can enable a reaction to be carried out under more moderate conditions.

Owner:YANSHAN UNIV

Method for preparing supported type photocatalyst by ionic imprinting method

InactiveCN104353501AHigh predictabilityEasy to identifyWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsPhysical chemistrySewage treatment

The invention discloses a method for preparing a supported type photocatalyst by an ionic imprinting method. The preparation process comprises the following steps: (1) preparing hydroxyapatite powder; (2) preparing TiO2 sol; (3) coating the hydroxyapatite powder with the TiO2 sol to obtain TiO2 / hydroxyapatite; and (4) adding heavy metal ion chitosan liquid to coat TiO2 / hydroxyapatite to obtain the chitosan / TiO2 / hydroxyapatite composite photocatalyst. Degradable chitosan and environment-friendly hydroxyapatite are selected in the aspect of application of raw materials, secondary pollution cannot be caused, and the environment-friendly effect is achieved; and certain heavy metal ions are introduced into the supported type photocatalyst by the ionic imprinting method, and therefore, the sewage treatment effect is improved obviously.

Owner:JIANGSU UNIV OF SCI & TECH

Nutrient soil for organic camellia oleifera culture

InactiveCN105638302APromote growthHigh porosityGrowth substratesCulture mediaCamellia oleiferaSeedling

The invention discloses nutrient soil for organic camellia oleifera culture. The nutrient soil is formed by mixing, fermenting and processing camellia oleifera shell ash, sweet potato waste, loess, animal waste, straw ash, bone meal, humic acid and active microbial flora. Specifically, the raw materials at certain percentages are mixed sufficiently, stirred with water, poured into a container and covered with a thin film, pile fermentation is conducted for 20-30 days at a temperature of 40 DEG C to 70 DEG C, and then the product can be taken out to serve as the nutrient soil. The nutrient soil can be effectively used for planting organic tea, especially culturing seedlings and has the advantages of being high in yield, green and the like.

Owner:叶鸿钊

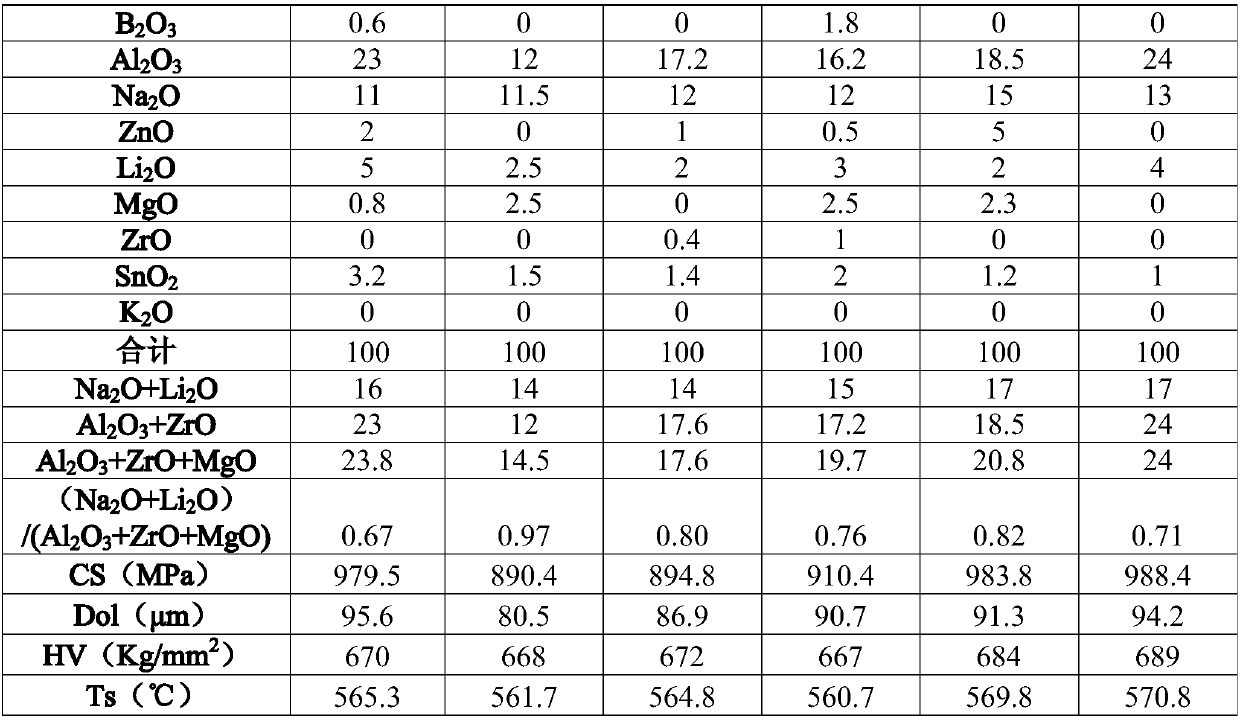

Chemical reinforced glass for electronic device and preparation method thereof

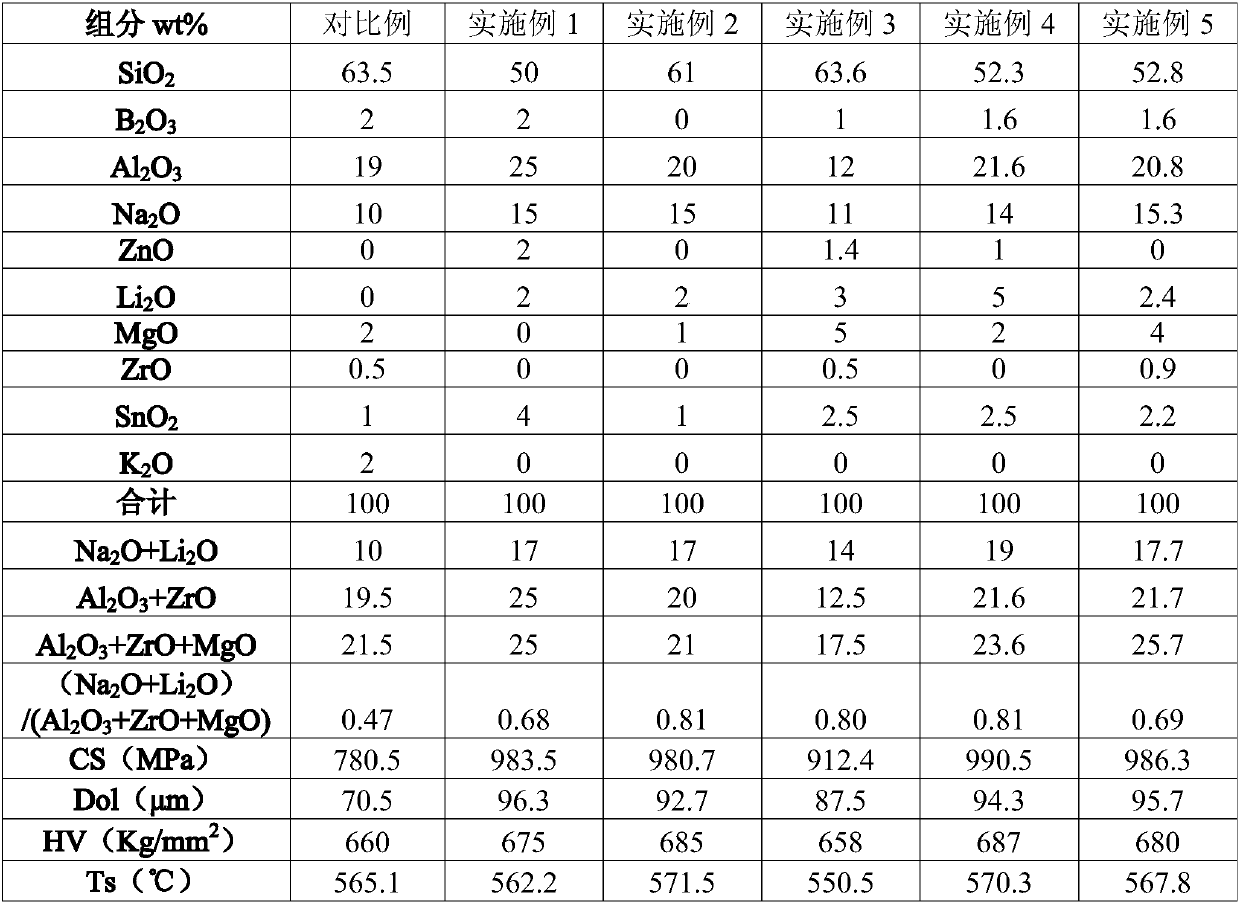

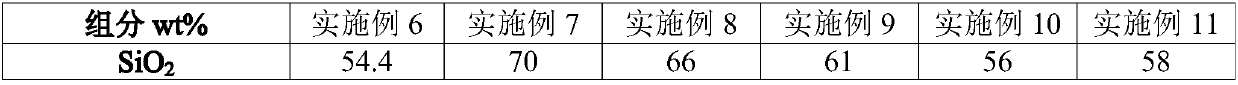

The invention provides chemical reinforced glass for an electronic device and a preparation method thereof. An ideal compression stress layer depth is obtained at relatively low reinforcing temperature and relatively short reinforcing time. The method comprises the following steps: 1) taking raw materials: greater than or equal to 50 percent and less than or equal to 70 percent of SiO2, greater than or equal to 0 percent and less than or equal to 2 percent of B2O3, greater than or equal to 12 percent and less than or equal to 25 percent of Al2O3, greater than or equal to 11 percent and less than or equal to 15 percent of Na2O, greater than or equal to 0 percent and less than or equal to 5 percent of ZnO, greater than or equal to 2 percent and less than or equal to 5 percent of Li2O, greater than or equal to 0 percent and less than or equal to 5 percent of MgO, greater than or equal to 0 percent and less than or equal to 1 percent of ZrO2, greater than or equal to 1 percent and less than or equal to 4 percent of SnO2 and greater than or equal to 0.67 and less than or equal to 0.97 of (Na2O+Li2O) / (Al2O3+ZrO2+MgO); 2) melting and clarifying and carrying out ion change. The surface compressive stress of the reinforced glass is 882.4MPa to 990.5MPa, the surface stress layer depth is 80.5mu m to 96.3mu m, the Vickers hardness is 658kg / mm<2> to 690kg / mm<2> and the strain point temperature is 550.5 DEG C to 572.2 DEG C.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Method for removing heavy metal ion from aqueous solution by using potassium tetratitanate

InactiveCN1394817AStrong ion exchangeEasy accessWater/sewage treatment by ion-exchangeIon exchangeIon

The potassium tetratitanate whiskers are used, and made into ion exchange column, the aqueous solution containing heavy metal ions is passed through said ion exchange column so as to remove the heavy metal ions from said aqueous solution, in which the potassium tetratitatnate whiskers can be made up by adopting the steps of mixing, sintering, quenching, dispersing treatment, separation, washing and high-temp. crystallization and sintering. Said ivnention is applicable to treatment of underground water source, other water source, industrial waste water containing heavy metal ions and nuclear waste liquor containing radioactive heavy metal ions.

Owner:HONGJIE LIGHT IND WUXI CITY

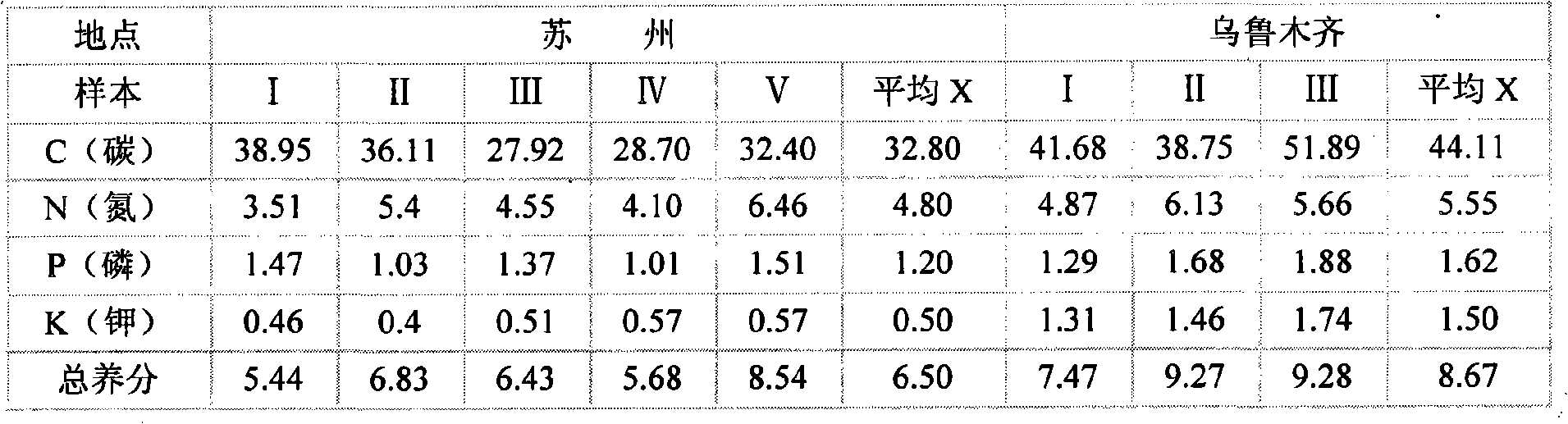

Improvement method of sludge compost

InactiveCN106747779ALow costReduce soluble salt concentrationExcrement fertilisersBioloigcal waste fertilisersFecesSludge compost

The invention provides an improvement method of sludge compost, and relates to the technical field of sludge treatment. The improvement method comprises the following steps: mixing sludge with zymophyte for fermentation; adding zeolite powder, urea, aluminum oxide, earthworm feces, coal ash, activated carbon, an improver and zymophyte and uniformly mixing, so as to obtain a mixed material; and placing the mixed material into fermentation equipment for fermentation, composting for one time for every 7-9 days, fermenting for 30-45 days and discharging. The sludge compost prepared by the method provided by the invention can be widely applied in agriculture, garden greens and roof greening, so that full utilization of sludge resources and environmental protection are facilitated, the waste of plant nutrients such as organic matters, nitrogen and phosphorus contained in sludge is avoided, and the secondary pollution to the environment is also avoided.

Owner:NINGBO UNIV

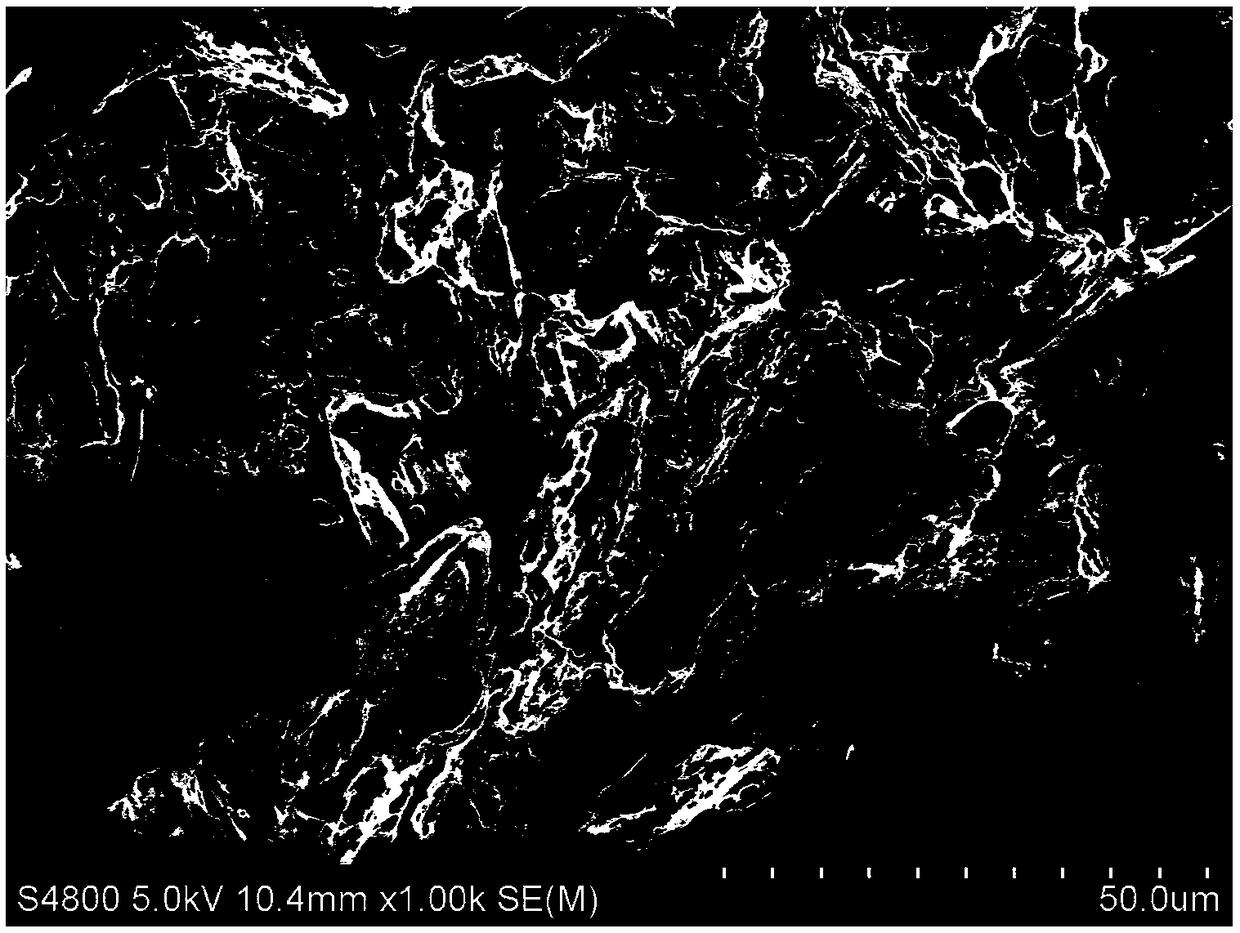

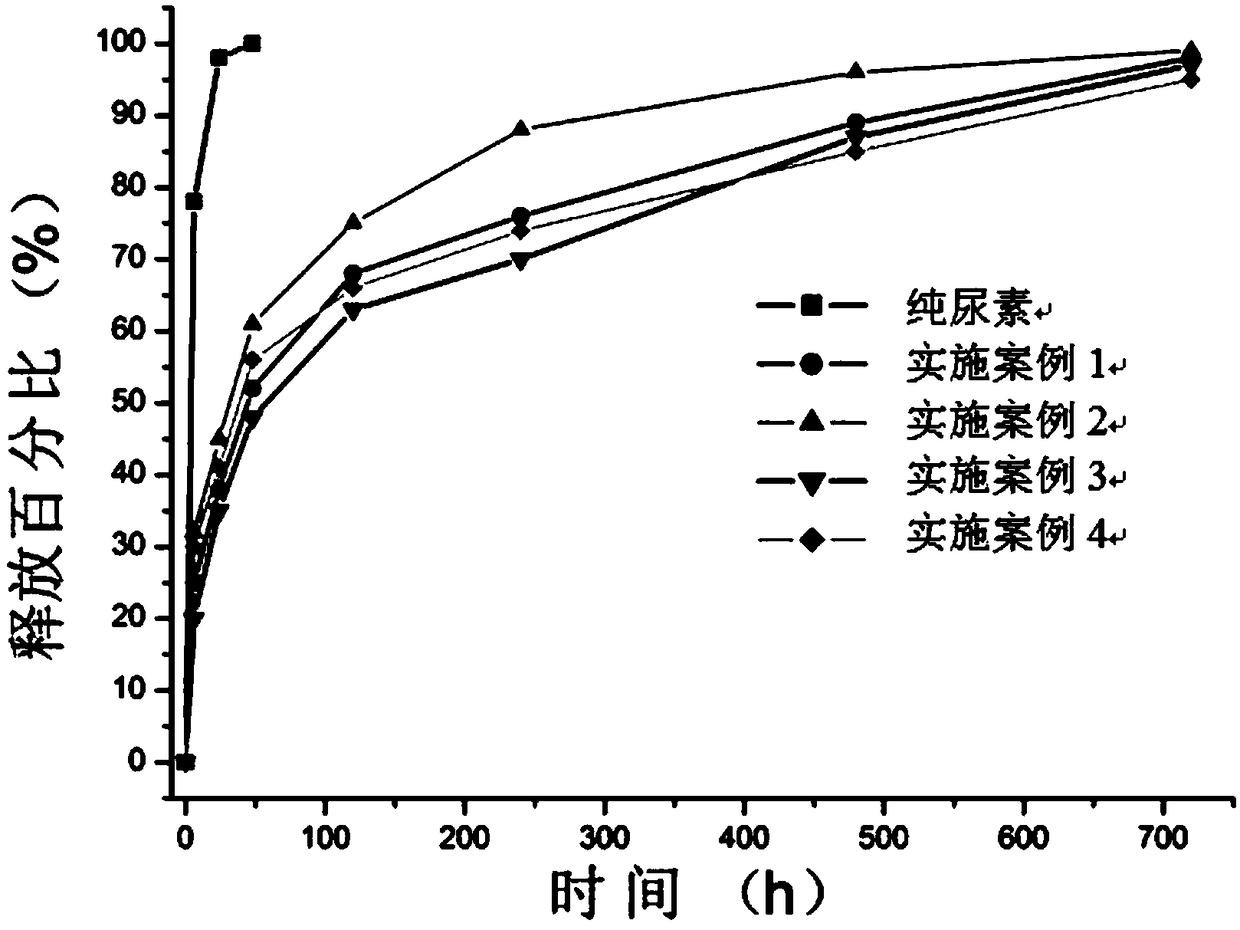

Biocharcoal-based slow release fertilizer and preparation method thereof

ActiveCN108314591AHigh specific surface areaHigh porosityUrea compound fertilisersFertilizer mixturesWear resistantIon exchange

The invention discloses biocharcoal-based slow release fertilizer. The biocharcoal-based slow release fertilizer is prepared from biocharcoal and chemical fertilizer with the mass ratio being 20:(5 to10). The biocharcoal-based slow release fertilizer disclosed by the invention has the beneficial effects that agricultural and forest wastes such as straws with wide distribution, large yield and lowcost are adopted as biomass, has rich pore channels, is easily decomposed, is not deteriorated after being absorbed, is wear-resistant, and also has excellent adsorbing and ion-exchange properties, the fertility, the structure and microorganisms and the like of soil can be effectively improved, and the soil quality can be improved; shown from the cumulative released amount of nitrogen of the biocharcoal-based slow release fertilizer in water, the cumulative released amount of the nitrogen in 480 hours is about 80%, i.e., the cumulative released amount of nitrogen nutrients in 20 days is 80%.The invention also discloses a preparation method of the biocharcoal-based slow release fertilizer. The preparation method adopts a hydrothermal method to prepare the biocharcoal-based slow release fertilizer, the technology is manure, the operation is convenient, simple and easy, low cost, less investment and low energy consumption are achieved, and an economic and feasible technical means is provided for large-scale application of the biocharcoal-based slow release fertilizer.

Owner:HUNAN AGRICULTURAL UNIV +1

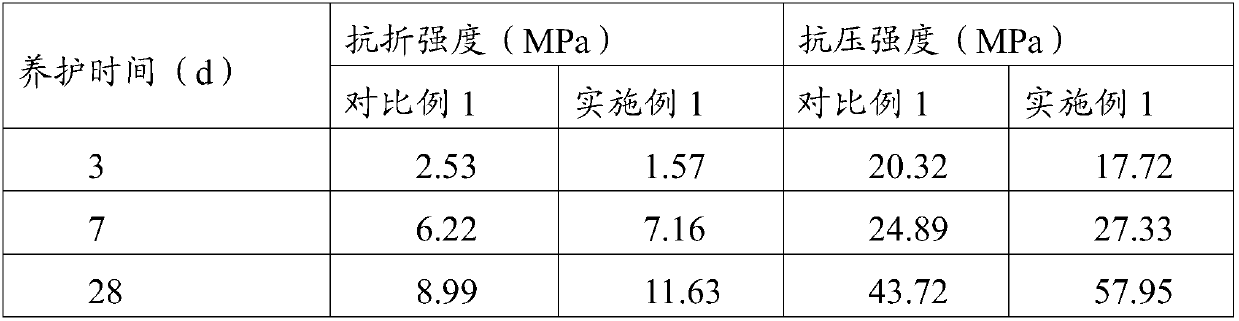

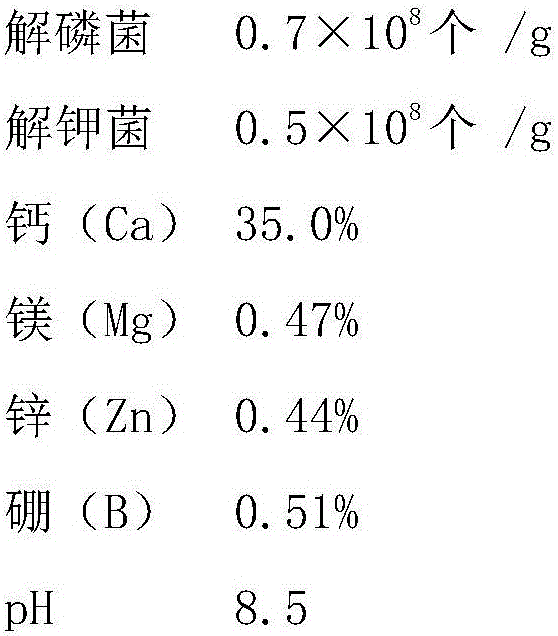

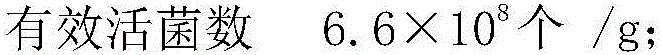

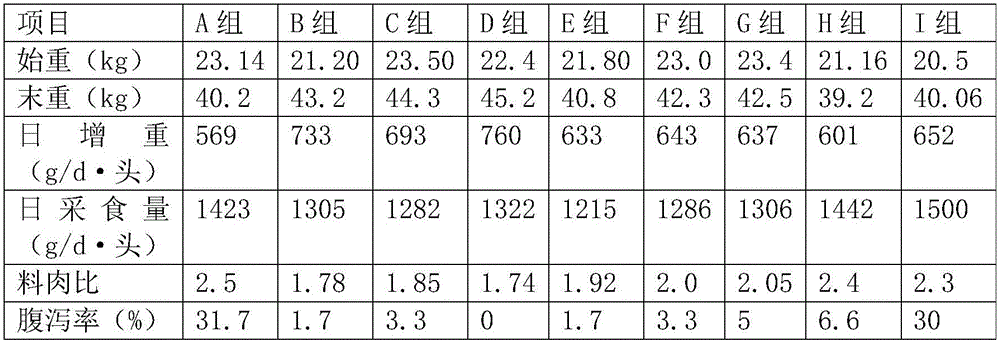

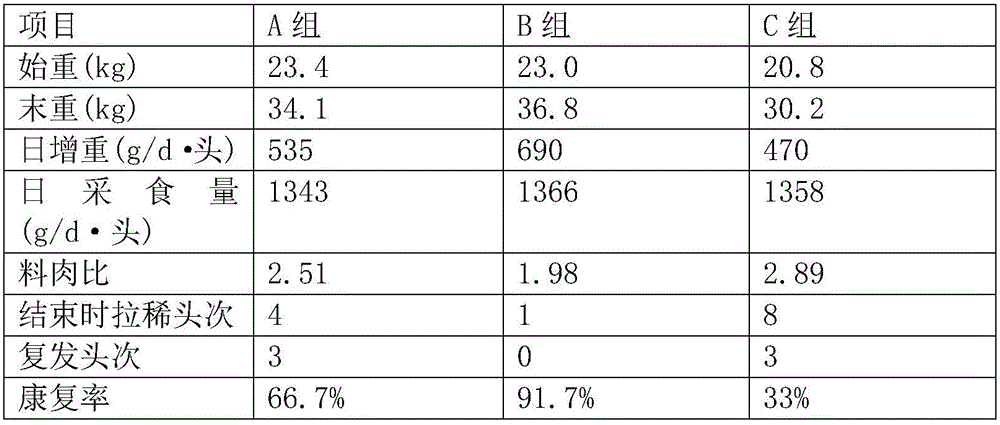

Vegetation concrete improved microbial agent and preparation method thereof

InactiveCN106590672APromote absorptionImprove physical and chemical propertiesAgriculture tools and machinesBacteriaSodium BentoniteAzotobacter chroococcum

A vegetation concrete improved microbial agent comprises the following raw materials in parts by weight: a mixed microbial fermentation powder, bentonite, diatomite, magnesium sulfate, zinc sulfate and boric acid, wherein the mixed microbial fermentation powder is prepared by the steps of carrying out press filtration, flash evaporation and drying of amplified cultured azotobacter chroococcum, bacillus megatherium and bacillus mucilaginosus, to respectively obtain dry powders of azotobacter chroococcum, bacillus megatherium and bacillus mucilaginosus, and mixing the dry powders according to a certain proportion. The vegetation concrete improved microbial agent and the preparation method thereof provided by the invention can solve the problem that the number and types of microorganisms cannot be increased as soon as possible; through the proportion of different beneficial microorganisms, a physicochemical environment of soil is changed, the biological chemical activity of the soil is improved, the fertilizer utilization ratio and the use effect are improved, ultimately, the growth of plants is promoted, and the purpose of the vegetation concrete fertility sustainability is achieved.

Owner:CHINA THREE GORGES UNIV

Sustained-release microcapsule-coated composite vitamin pre-mixed feed, preparation method and application thereof

The invention provides a sustained-release microcapsule-coated composite vitamin pre-mixed feed which has good stability and has sustained-release and bacterial inhibiting and sterilizing effects. 1 kg of the pre-mixed feed includes the following components, 20-100 g of microcapsule-coated composite vitamin, 20-50 g of amino acid chelated iron, 5-18 g of amino acid chelated copper, 20-45 g of amino acid chelated zinc, 4-5 g of manganese sulfate monohydrate, 0.10-0.11 g of 1% potassium iodate, 0.59-0.68 g of cobalt chloride, 0.05-0.14 g of 1% sodium selenite, 20-30 g of arginine, 5.9-6.4 g of threonine, 1.8-6.5 g of an enzyme preparation, 18-70 g of an acidification agent, 1.1-3.0 g of an anti-oxidizing agent, 8-50 g of a flavoring agent, 7.5-9.0 g of medicine additives, 78-95 g of 50% choline chloride and the balanced being a carrier which includes nano chelated attapulgite, and at least one of corn protein powder, stone powder, zeolite powder, medical stone or montmorillonite.

Owner:GUANGZHOU GREAT BIOLOGICAL TECH

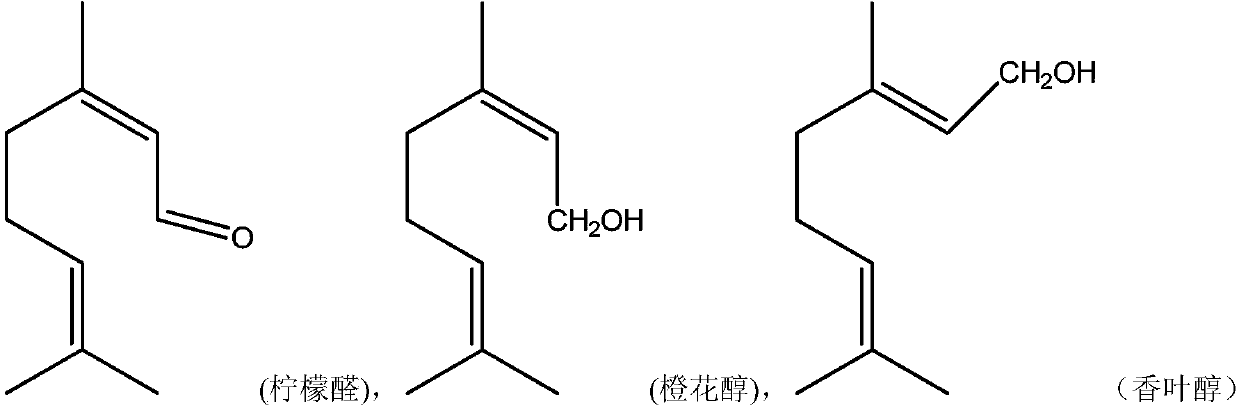

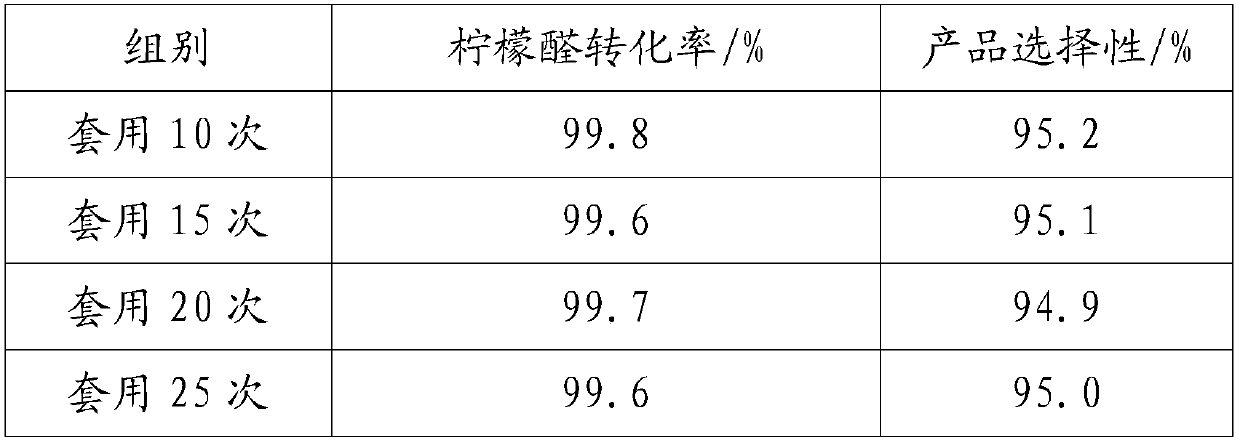

Catalyst and method for preparing nerol and geraniol by using same

ActiveCN109622050AStrong ion exchangeHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPt elementZirconium dioxide

The invention provides a catalyst and a method for preparing nerol and geraniol by using the same. By utilizing the method, a reaction can be carried out under mild conditions, the nerol and the geraniol can be prepared with high yield under the catalysis of the catalyst, and the method has the advantages of simple reaction process, low reaction cost, environmental friendliness and the like. According to the preparation method of the catalyst, zirconium dioxide is used as a carrier, and chitosan, platinum metal precursors and nickel metal precursors are loaded on the zirconium dioxide to prepare the catalyst; preferably, the mass ratio of the amount of the chitosan to the amount of the platinum metal precursors in terms of the platinum element is 0.1-10:1, preferably 4-6:1; the molar ratioof the platinum metal precursors in terms of the platinum element to the nickel metal precursors in terms of the nickel element is from 1:3-3:1, preferably from 1:1-2:1.

Owner:WANHUA CHEM GRP CO LTD

Method for manufacturing modified extract and method for reducing heavy metal ion content in paper-making tobacco sheet

ActiveCN102960850BReduce the content of heavy metal ionsStrong ion exchangeTobacco preparationTobacco treatmentIon exchangePaper based

The invention provides a preparation method of a modified extracting solution and a method for reducing contents of heavy metal ions in a papermaking method tobacco sheet. The extracting solution is prepared by adopting modified epidesmine, and used for a technology for the low contents of the heavy metal ions in dipping and coating production of the papermaking method tobacco sheet. The available heavy metal materials are mainly produced by factors such as soil, air and fertilizer for tobacco planting, and a mechanical contact in a tobacco manufacturing procedure, and tobacco stems and tobacco powder for manufacturing the tobacco sheet come from natural tobacco leaves. A paper base is recoated by extracts of the tobacco stems and tobacco powder in the manufacturing process of the papermaking method tobacco sheet. The modified epidesmine has a very good ion-exchange property; and after the epidesmine is added to recoated paint for reaction, the modified zeolite is removed by filtering, so that the contents of the heavy metal ions in the tobacco sheet are lowered, cigarettes have no offensive odor, and the method has the characteristic of simple technology, and the cost is lowered.

Owner:CHINA TOBACCO GUANGDONG IND

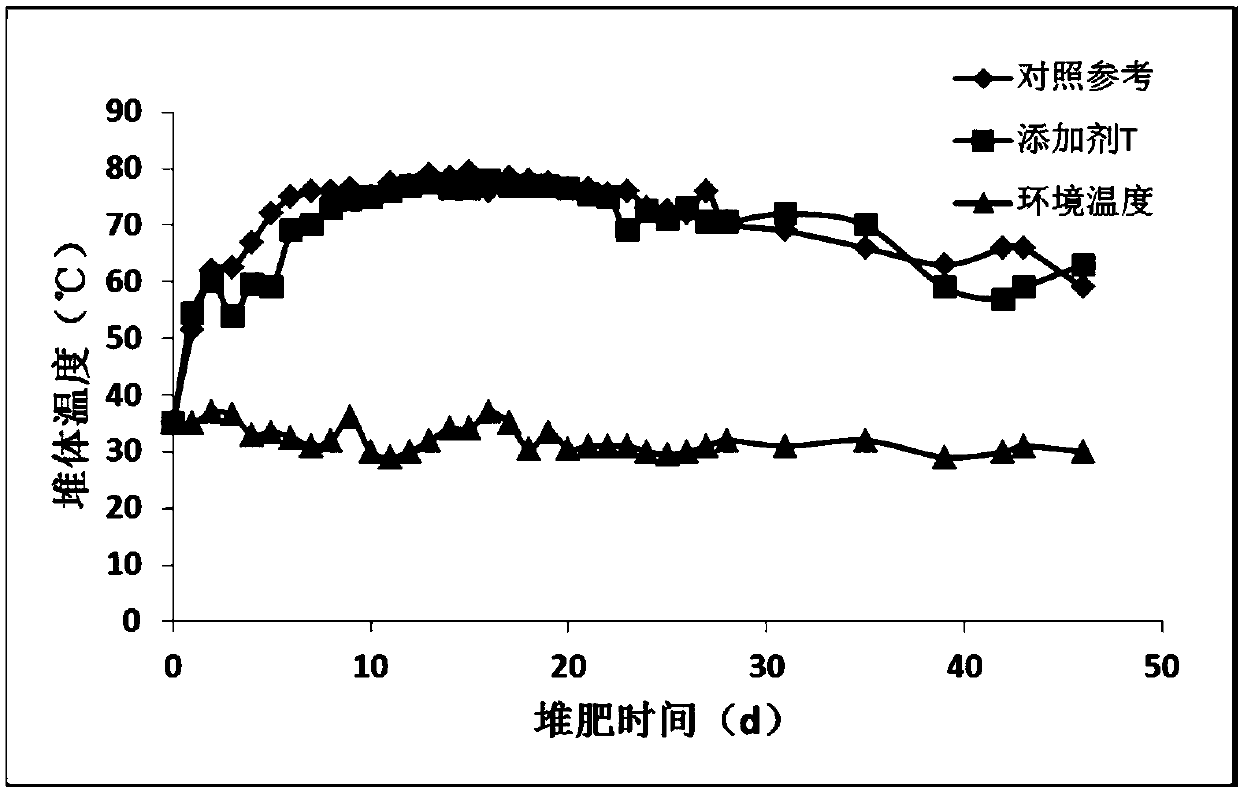

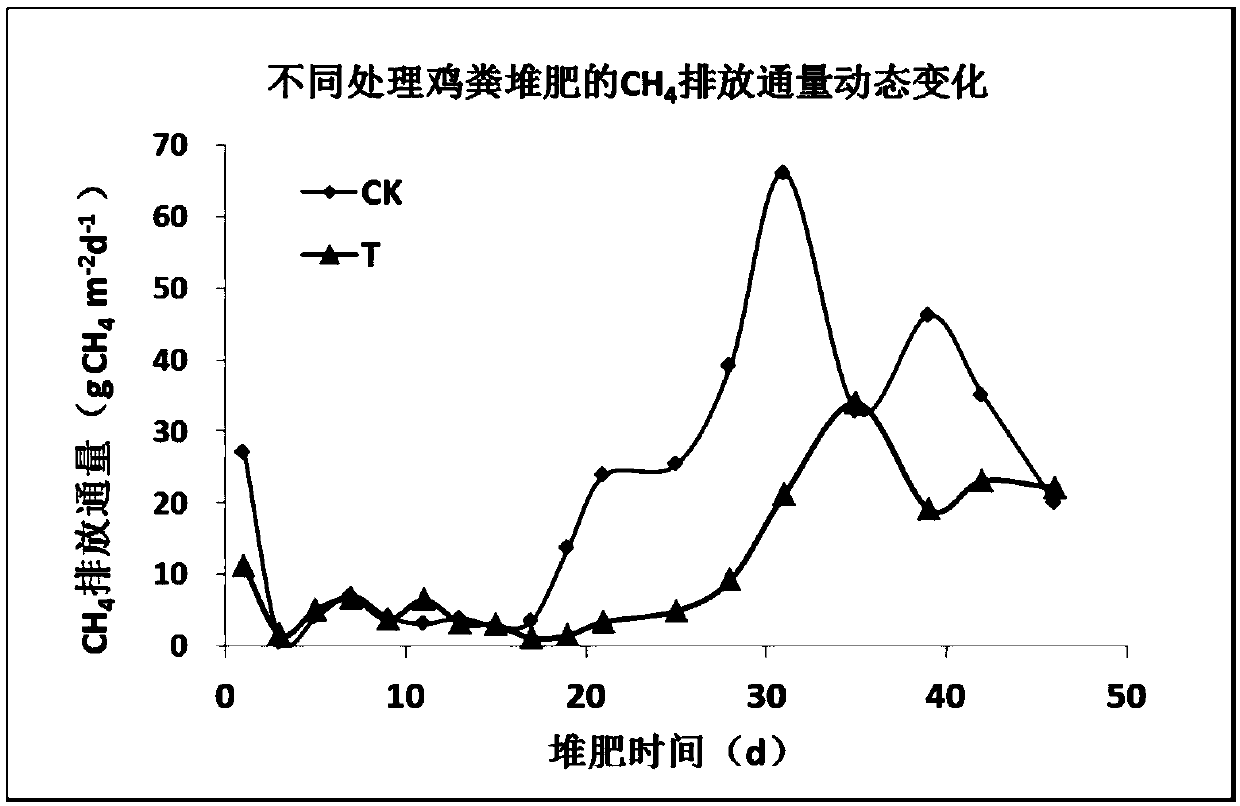

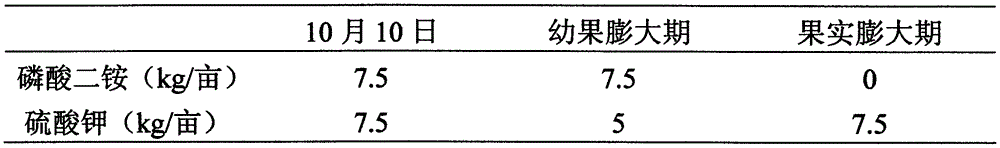

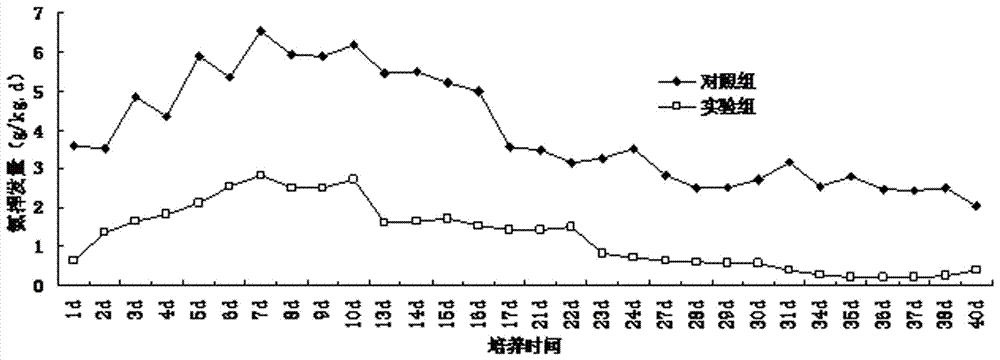

Additive for reducing greenhouse gas emission of livestock manure compost and application thereof

InactiveCN109650948AQuality improvementEmission reductionBio-organic fraction processingClimate change adaptationLivestock manureSulfate

An additive for reducing greenhouse gas emissions of livestock manure compost and application thereof are disclosed. The additive is a mixture composed of zeolite, ferrous sulfate, Bacillus subtilis WJC11 and Bacillus cereus WJC2 in a mass ratio of 50:30:1:1. The additive is used under the conventional operation process of compost. Compost production can be ensured while compost quality is improved, and emission of greenhouse gas in the composting process is preferentially reduced. Thereby, the environmental pollution caused by the gas release during the composting process is effectively controlled.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Feed balanced in nutrition and capable of reducing morbidity of bass

InactiveCN107259206AReasonable nutritionNutritional balanceFood processingClimate change adaptationSOYBEAN SEED OILPeanut meal

The invention discloses feed balanced in nutrition and capable of reducing the morbidity of bass. The feed is prepared from the following raw materials: extruded soybeans, wheat flour, rice bran, peanut meal, fish meal, earthworm powder, seaweed powder, fermented blood meal, modified montmorillonoid, composite Chinese herbal medicine, decavitamin, probiotics, soybean oil, syringic acid, betaine, citric acid, sodium diacetate, inositol, xanthan gum and sodium polyacrylate. According to the feed balanced in nutrition and capable of reducing the morbidity of the bass, disclosed by the invention, the feed is reasonable in formula, balanced in nutrition and good in palatability, is green and environmentally friendly and is high in utilization rate, the physique of the bass is effectively improved, the morbidity of the bass is reduced, growth and development of the bass are promoted, the bass is good in meat quality, the economic benefit of bass cultivation is increased, and meanwhile, the ecological environment of a water body is effectively improved.

Owner:天长市金农农业发展有限公司

Preparation method of absorbent used for removing mercury vapor pollutant

InactiveCN102513056AImprove adsorption capacityStrong ion exchangePhysical/chemical process catalystsOther chemical processesAlcoholSilicic acid

The invention discloses a preparation method of an absorbent used for removing mercury vapor pollutants. The invention belongs to the technical field of chemical engineering. The method comprises steps that: bentonite, cetyl trimethyl ammonium bromide, dodecylamine, polyhexylene alcohol, and tetraethoxysilane are prepared; a bentonite suspension liquid is mixed with cetyl trimethyl ammonium bromide; the mixture is uniformly mixture, dodecylamine and polyhexylene alcohol are added to the mixture, and the obtained mixture is mixed; tetraethoxysilane is added to the mixture, until precipitate is formed; the precipitate is separated and dried, such that powder of the precipitate is obtained; a mixed solution of titanium tetrachloride and dialuminium trichloride is prepared; the prepared powder is soaked in the mixed solution; the mixed solution is stood; excess dilute ammonia water is dropped into the mixed solution, and a reaction is carried out for 12h; the obtained product is subject to drying treatment; the product is annealed, such that the absorbent is prepared. With the method, thermal stability of a system is greatly improved, and the method is environment friendly.

Owner:JIANGSU SIFANG BOILER

Soil conditioner with strawberry continuous cropping disease prevention function and preparation method of soil conditioner

InactiveCN105294236AAppropriate ratioSuitable processFertilizer mixturesContinuous croppingPlant disease

The invention relates to a soil conditioner with a strawberry continuous cropping disease prevention function and a preparation method of the soil conditioner. A continuous cropping agent consists of the following eight raw materials by weight: 60-80 parts of shale, 10-15 parts of zeolite, 0.6-1 part of soybean meal, 2-4 parts of rice bran, 0.6-1 part of rice hull powder, 0.2 to 0.6 part of brown sugar, 1-2 parts of enzyme microorganism, and 1-2 parts of a compound chelating microorganism fertilizer. Strain, rice bran, rice hull powder, a compound chelating agent, soybean meal, brown sugar, shale and zeolite are mixed and stirred, then fermentation is carried out under a certain condition, and after fermentation, the obtained powder can be applied to a field or air-dried (or dried at low temperature) for storage, or extruding granulation is conducted on the fermented powder, and the obtained particles are air-dried (or dried at low temperature) for storage. The invention aims to provide a compound continuous cropping agent which can improve the physical and chemical properties and the microflora of soil, activate soil nutrients and effectively inhibit the soil-borne disease of plant to effectively relieve continuous cropping barrier of crops.

Owner:辽宁津大肥业有限公司

Biochar mixing type protected horticultural vegetable field soil heavy metal passivant and preparation method thereof

InactiveCN102807872BSimple processNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil heavy metalsStone dust

The invention relates to a soil improvement technology and an environment protection technology and particularly discloses a biochar mixing type protected horticultural vegetable field soil heavy metal passivant and a preparation method thereof. The soil heavy metal passivant comprises the following components in percentage by weight: 50 to 60 percent of biochar, 5 to 10 percent of medical stone powder, 5 to 10 percent of diatomite powder, 10 to 20 percent of lignite and 10 to 20 percent of coal ash. The preparation method for the soil heavy metal passivant comprises the following steps of: mixing the medical stone powder which is screened by an 80-mesh sieve, the diatomite powder which is screened by an 80-mesh sieve, the lignite, and the coal ash which is screened by an 80-mesh sieve, uniformly stirring, mixing with biochar which is screened by a 20-mesh sieve, fully stirring, and mixing uniformly to prepare the soil heavy metal passivant. The soil heavy metal passivant is easy to prepare; and the effects of passivating the protected horticultural vegetable field soil heavy metal, and reducing the content of recyclable heavy metal of plant in soil can be achieved under the synergistic effects of all components.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Conditioner for reducing ammonia volatilization during chicken manure composting and preparation method of conditioner

PendingCN107056477AWide variety of sourcesLow costCalcareous fertilisersSuperphosphatesSodium BentoniteMicrobial agent

The invention discloses a conditioner for reducing ammonia volatilization during chicken manure composting and a preparation method of the conditioner. The conditioner is prepared from mushroom dreg, turf, vermiculite, strawcarbon powder, phosphorite powder, modified zeolite powder, calcium bentonite, wood vinegar, monocalcium phosphate and a microbial agent. The conditioner is reasonable in compatibility of all components and good in ammonia volatilization prevention effect, improves the composting quality, and has advantages of physical, chemical and biological conditioners at the same time; the preparation method is simple, and the process is easy to control. The conditioner is applicable to promotion and application in organic fertilizer plants and livestock farms, takes chicken manure as a raw material, and reduces ammonia volatilization produced during composting.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT HEBEI ACADEMY OF AGRI & FORESTRY SCI

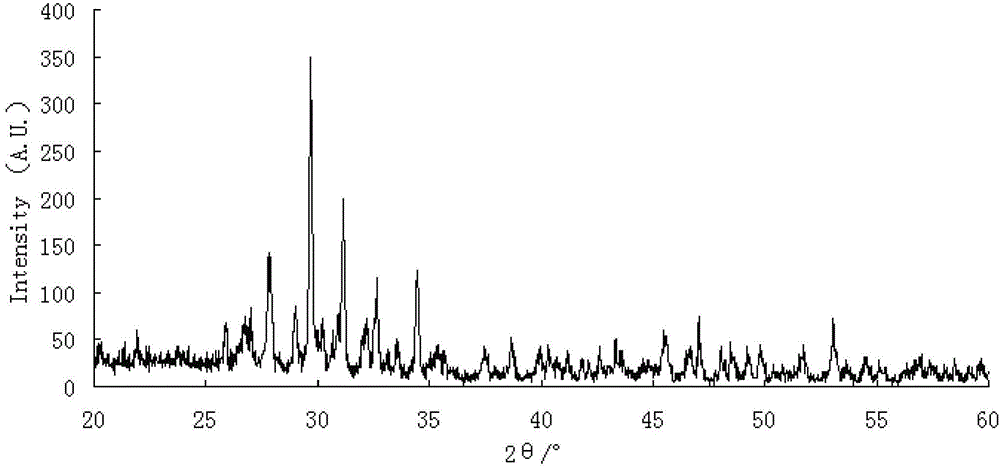

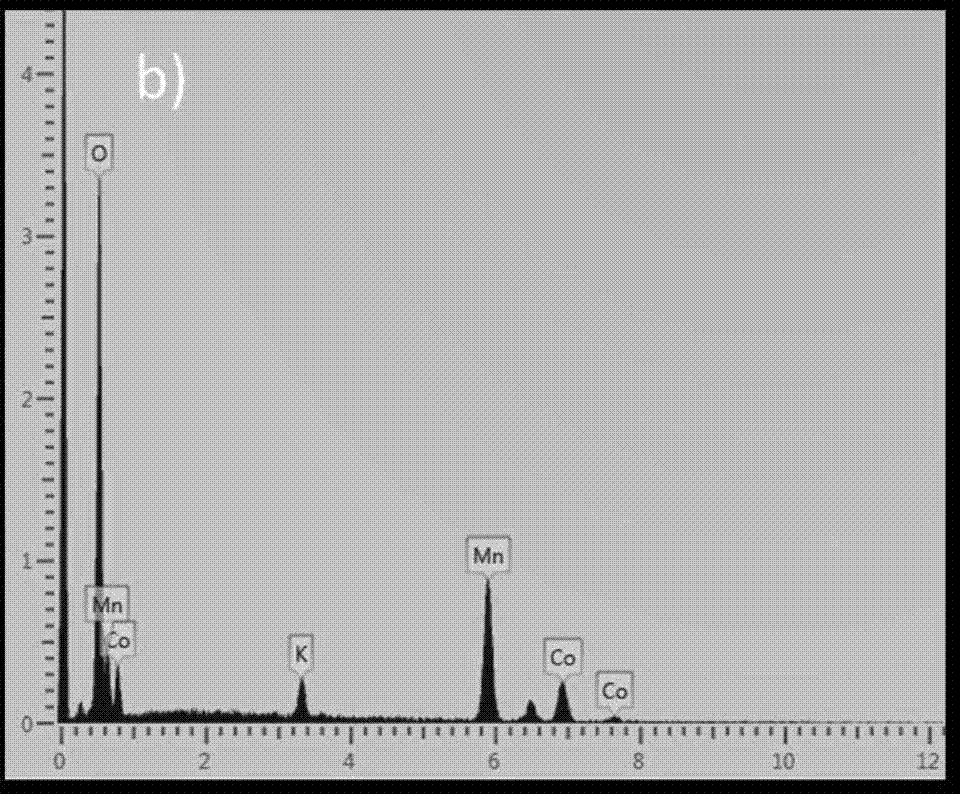

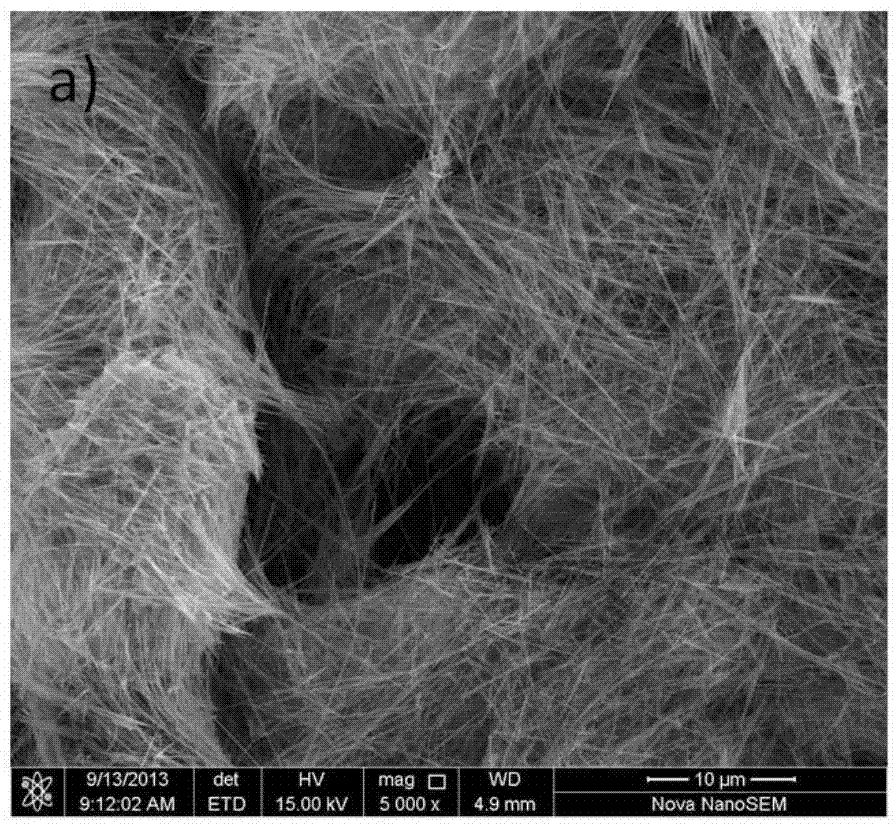

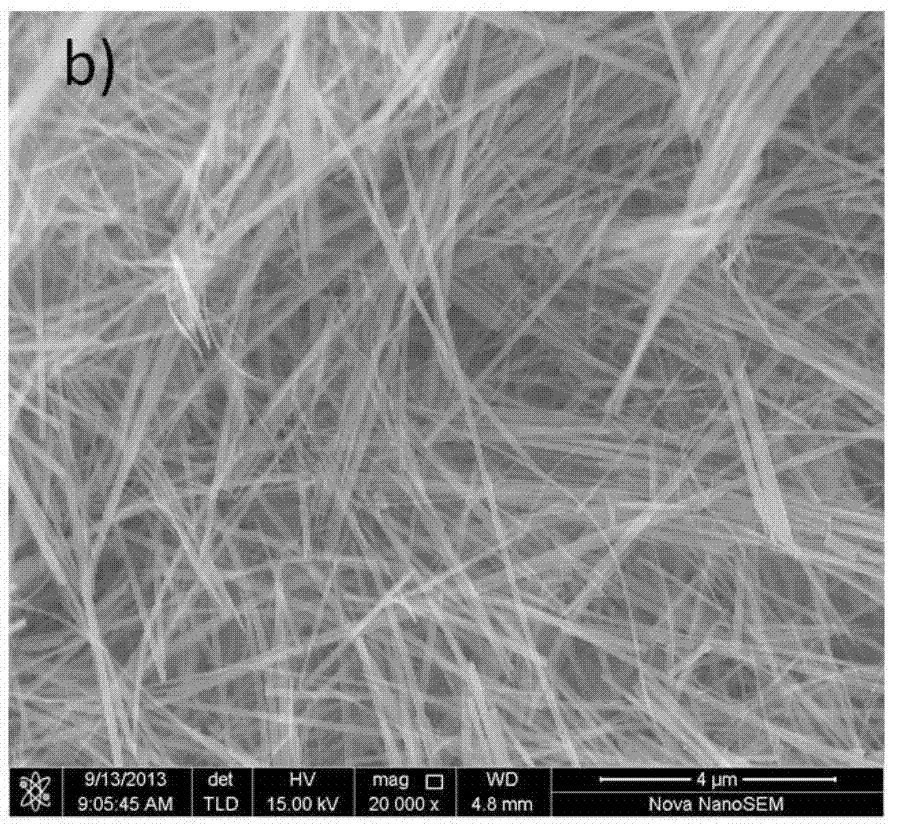

Cryptomelane-type K(2-x)CoyNizMn(8-y-z)O16 nanowire and preparation method thereof

ActiveCN103774236AHigh crystallinityHigh catalytic activityMaterial nanotechnologyPolycrystalline material growthData displayNanowire

The invention relates to a cryptomelane-type K(2-x)CoyNizMn(8-y-z)O16 nanowire, which is prepared by the following steps: mixing and dissolving potassium permanganate, a soluble bivalent cobalt salt and / or soluble bivalent nickel salt into water according to a proper molar ratio to obtain a mixed solution; carrying out heating reaction inside a sealed container under the conditions that the temperature is 150-220 DG C and the pressure is 2-3MPa for 10-24 hours. The data display that the cryptomelane-type K(2-x)CoyNizMn(8-y-z)O16 nanowire is a single compound, and belongs to a tetragonal system. In the cryptomelane-type K(2-x)CoyNizMn(8-y-z)O16 nanowire disclosed by the invention, the structure is stabilized after lattice positions of a part of manganese ions are substituted by cobalt ions and / or nickel ions. Meanwhile, the physical and chemical properties such as catalytic activity, gas adsorption property and the like are improved by the synergistic effects of a few of elements of cobalt, nickel and manganese. Thus, the application prospects of the nanowire in the fields such as catalysis, sensing, a lithium ion battery, a solid fuel battery and the like are expanded.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

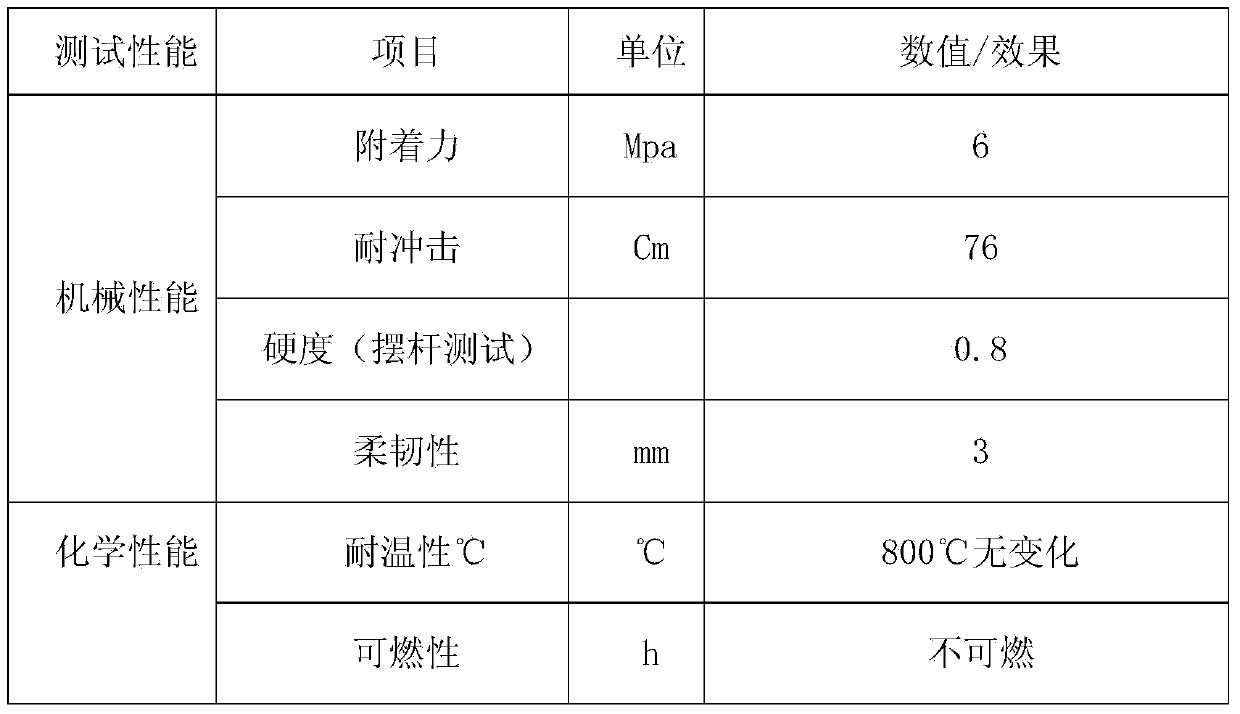

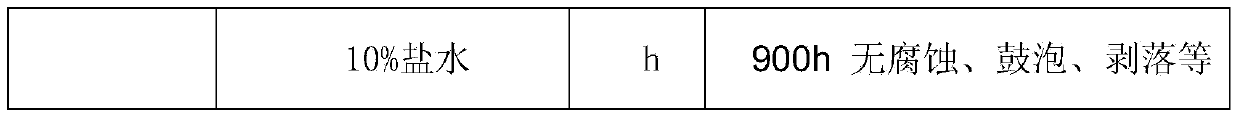

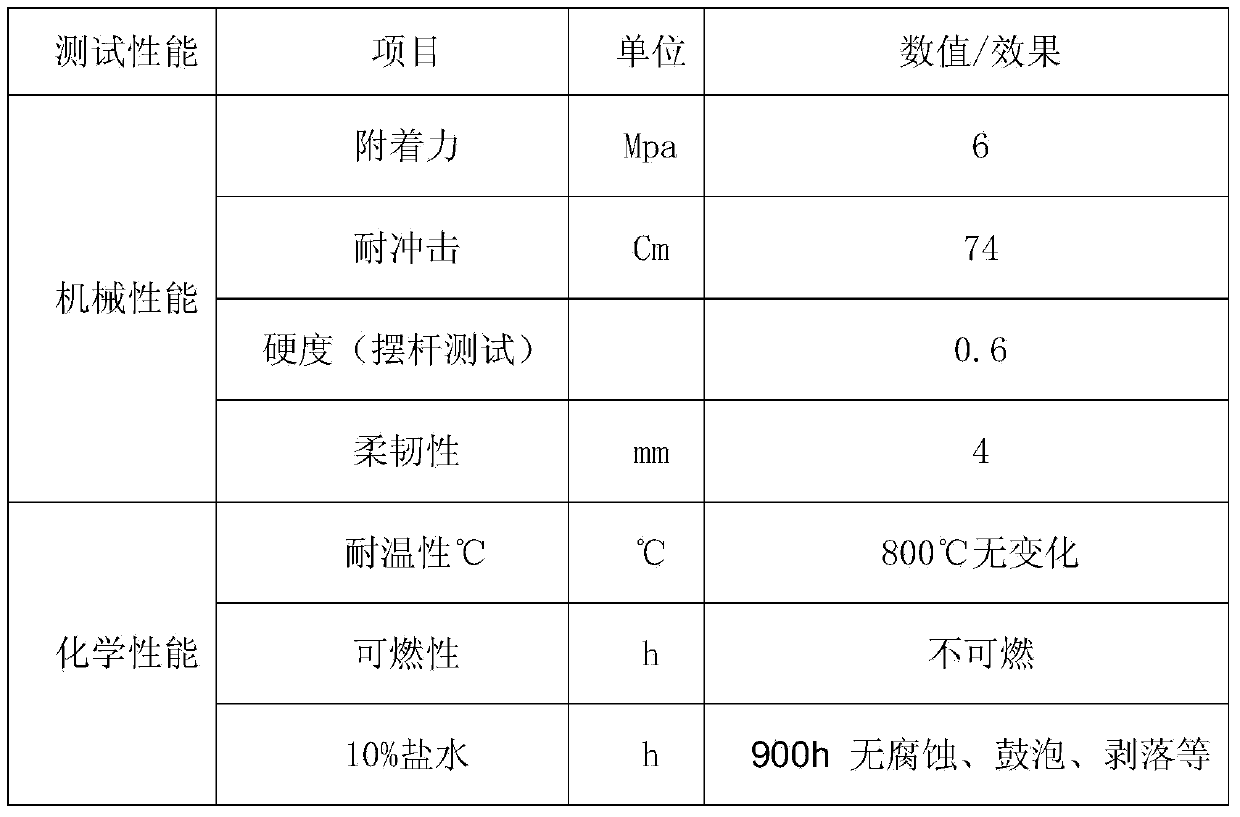

Method for preparing VCI double-metal composite coating

InactiveCN104194620AGood coating glossStrong metal textureAnti-corrosive paintsComposition BTemperature resistance

The invention discloses a method for preparing a VCI double-metal composite coating. The VCI double-metal composite coating comprises the following components: a grafted organic silicon resin, aluminum powder, zinc powder and aids. The preparation method comprises the following steps: adding the grafted organic silicon resin and the aids into a dispersing vat, stirring to prepare a premix; and adding the aluminum powder and zinc powder, stirring, standing, thereby obtaining the VCI double-metal composite coating. The invention also discloses a preparation method of the VCI double-metal composite coating. The VCI double-metal composite coating consists of a composition A and a composition B, wherein the composition A and the composition B are mixed to prepare the VCI double-metal composite coating. The preparation method is simple and feasible to operate, and the preparation process is environment-friendly, low in consumption and low in cost. The composite coating prepared by the method has the advantages of good mechanical property, good adhesion force, high impact resistance, high hardness, high flexibility, good chemical performance, high-temperature resistance, high flame retardant property and high corrosion resistance and can well protect metal.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com