Glass for chemical tempering

A chemical tempering and glass technology, applied in the field of glass, can solve the problems of shallow ion exchange layer, poor impact resistance, and poor bending strength of glass, and achieve excellent ion exchange performance and good crystallization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

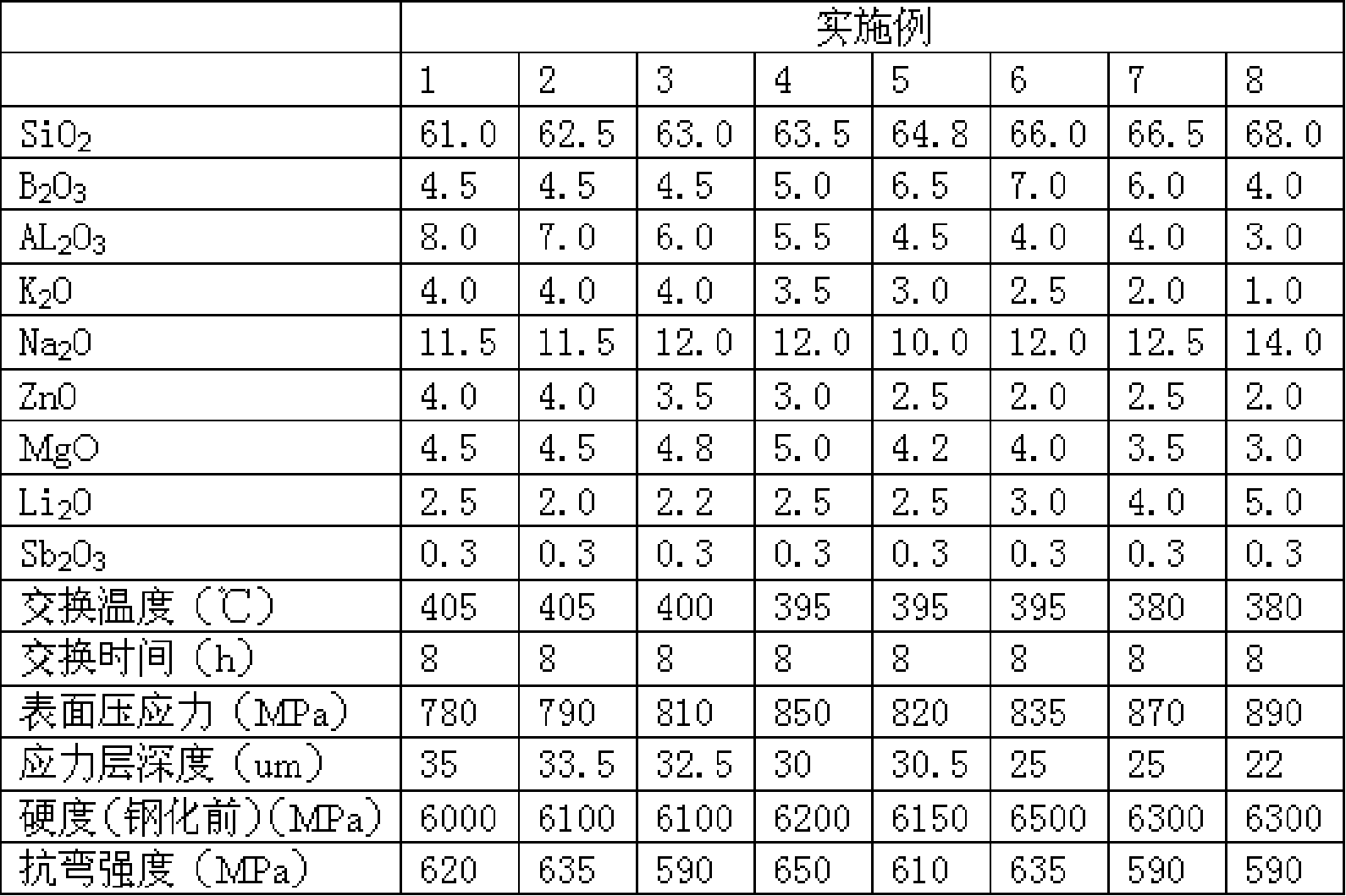

Examples

Embodiment Construction

[0008] SiO 2 It is a glass former. When its content is less than 60%, the chemical stability and mechanical properties of the glass are not good; when it exceeds 70%, the melting temperature is too high and it is not easy to melt. Therefore, SiO 2 The content is 60-70%.

[0009] Al 2 o 3 It can inhibit phase separation and improve chemical strengthening properties. When its content is below 3%, the effect is not obvious; when it exceeds 8%, the liquidus temperature and glass transition point temperature will increase significantly, and the melting performance will also deteriorate. Therefore, Al 2 o 3 The content is 3-8%.

[0010] Li 2 O can improve the strengthening characteristics when the glass surface is ion-exchanged with Na ions or K ions, the main components in the ion-exchange treatment solution, and can also reduce the liquidus temperature and transition temperature of the glass. Li 2 The content of O is 1-5%.

[0011] Na 2 O can improve the strengthening cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com