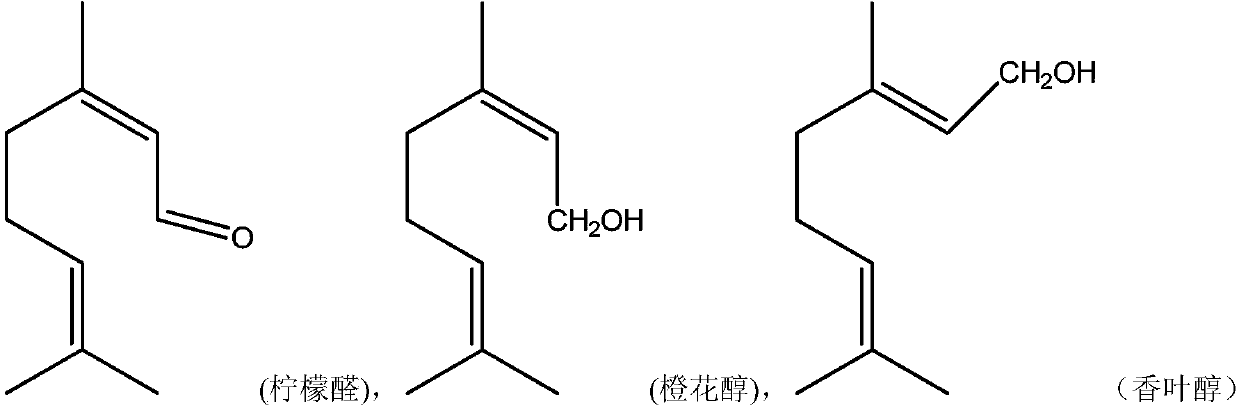

Catalyst and method for preparing nerol and geraniol by using same

A catalyst, nerol technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem that reactivity, selectivity and stability cannot be taken into account at the same time, increase separation difficulty, and complex preparation process, etc. problems, to achieve the effect of improving conversion rate and selectivity, good industrialization prospects, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

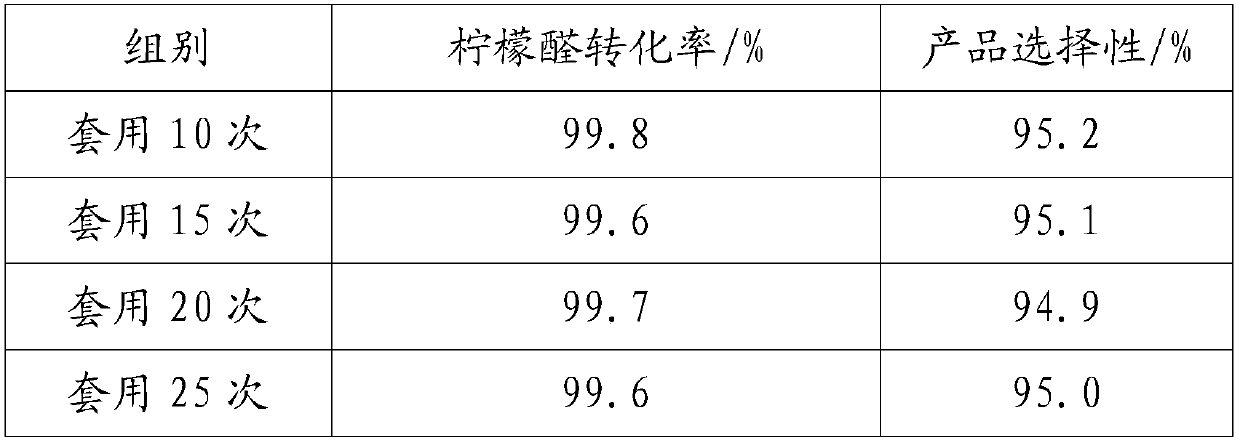

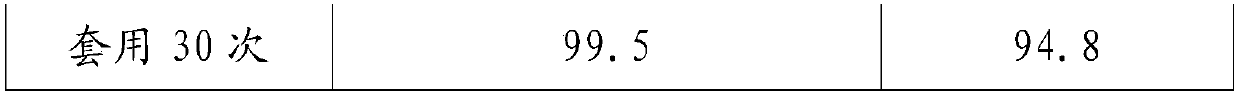

Embodiment 1

[0060] 1.507g of chitosan was dissolved in 90ml of 1.5% aqueous acetic acid solution, heated and stirred until completely dissolved; a chitosan solution was obtained.

[0061] 0.49 g of zirconium dioxide was dispersed in 61.3 ml of deionized water in the flask. After fully stirring with the chitosan solution, add 1g of chloroplatinic acid hexahydrate, 0.459g of nickel chloride hexahydrate and 3.767g of PVP and stir at room temperature until completely dissolved. Then add 0.584g of sodium borohydride, and stir the reaction at room temperature for 4h. The reacted solution was centrifuged, washed with deionized water until neutral, and dried at 120° C. for 12 hours to obtain a catalyst.

[0062] During the catalyst preparation process, the mass ratio of chitosan to platinum is 4:1, the molar ratio of platinum to nickel is 1:1; the mass ratio of PVP to platinum is 10:1; the loading mass of zirconia is 50% (Based on the total mass of platinum, nickel and zirconium dioxide in the ...

Embodiment 2

[0064] 2.26g of chitosan was dissolved in 135.6ml of 1.5% aqueous acetic acid solution, heated and stirred until completely dissolved; a chitosan solution was obtained.

[0065] 0.5643 g of zirconium dioxide was dispersed in 62.7 ml of deionized water in a flask. After fully stirring with the chitosan solution, add 1g of chloroplatinic acid hexahydrate, 0.344g of nickel chloride hexahydrate and 4.144g of PVP and stir at room temperature until completely dissolved. Then add 0.657g of sodium borohydride, and stir the reaction at room temperature for 5h. The reacted solution was centrifuged, washed with deionized water until neutral, and dried at 130° C. for 15 hours to obtain a catalyst.

[0066] During the catalyst preparation process, the mass ratio of chitosan to platinum is 6:1, the molar ratio of platinum to nickel is 4:3; the mass ratio of PVP to platinum is 11:1; the loading mass of zirconia is 55% (Based on the total mass of platinum element, nickel element and zirconi...

Embodiment 3

[0068] 1.507g of chitosan was dissolved in 90ml of 1.5% aqueous acetic acid solution, heated and stirred until completely dissolved; a chitosan solution was obtained.

[0069] 0.65 g of zirconium dioxide was dispersed in 65 ml of deionized water in a flask. After fully stirring with the chitosan solution, add 1g of chloroplatinic acid hexahydrate, 0.248g of nickel acetylacetonate and 4.52g of PVP at room temperature and stir until fully dissolved. Then add 0.73g of sodium borohydride, and stir the reaction at room temperature for 6h. The reacted solution was centrifuged, washed with deionized water until neutral, and dried at 110° C. for 18 hours to obtain a catalyst.

[0070] During the preparation of the catalyst, the mass ratio of chitosan to platinum is 4:1, the molar ratio of platinum to nickel is 2:1; the mass ratio of PVP to platinum is 12:1; the loading mass of zirconia is 60 % (based on the total mass of platinum, nickel and zirconium dioxide in the raw materials us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com