Method for synthesizing zeolite from fine coal gasification slag, and zeolite material prepared therethrough

A technology for synthesizing zeolite and coal gasification, which is applied in the field of solid waste resource utilization and achieves the effects of simple preparation process, low cost and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 100g coal gasification fine slag (wherein water content is 55%), add water and dilute to solid content is 10%, adopt high-speed dispersing mixer (Guangdong Foshan Yifu Machinery Co., Ltd.) to stir under normal temperature, stirring speed is 1600r / min, stirring time is 50min; the slurry was introduced into a cyclone separator for separation, and the obtained lower slurry was a silicon-rich slurry. After testing, the carbon content in the solid phase was 6.8wt%, and most of the carbon was separated in the upper part;

[0034] Adjust the solid content of the silicon-rich slurry to 10wt%, according to the water content, add sodium hydroxide and dissolve it in water to make the concentration reach 10wt%; stir and age for 2 hours; the aging temperature is 60°C to obtain the precursor;

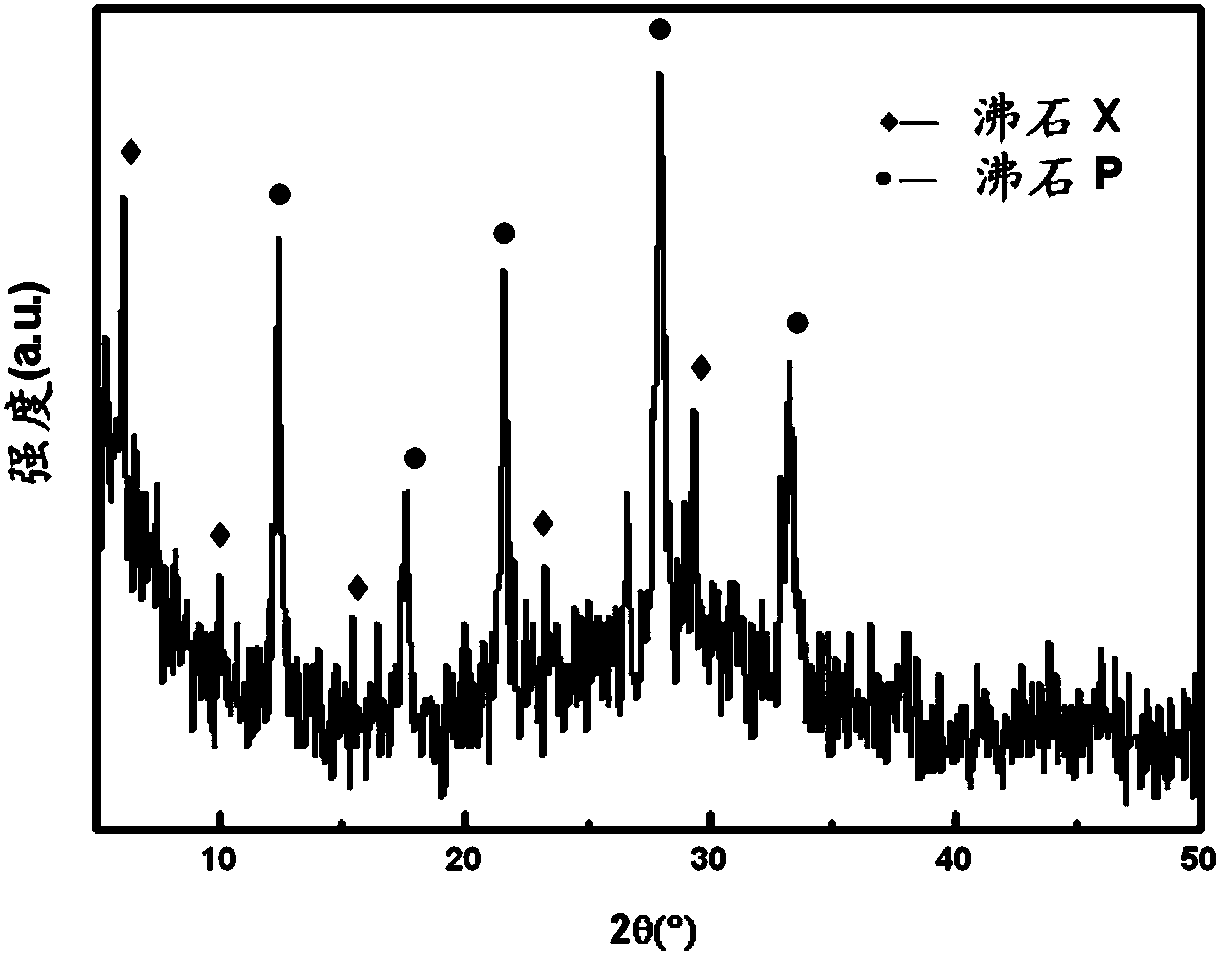

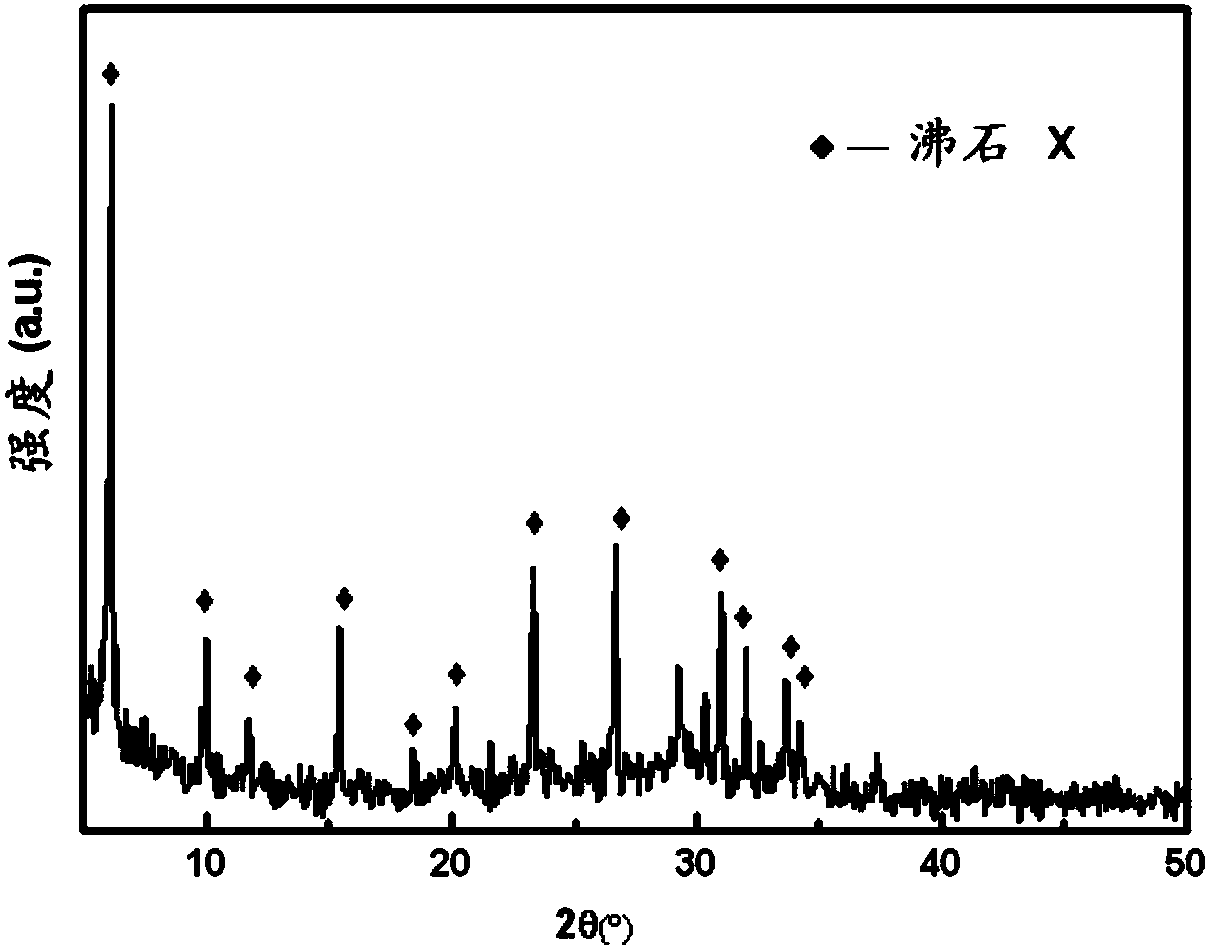

[0035] The obtained precursor was moved into a sealed reaction kettle for hydrothermal synthesis, the crystallization temperature was 100°C; the crystallization time was 8h, then washed w...

Embodiment 2

[0037] Weigh 100g coal gasification fine slag (wherein water content is 55%), add water and dilute to solid content is 20%, adopt high-speed dispersing mixer (Guangdong Foshan Yifu Machinery Co., Ltd.) to stir under normal temperature, stirring speed is 1700r / min, stirring time is 40min; the slurry was introduced into a cyclone separator for separation, and the obtained lower slurry was a silicon-rich slurry. After testing, the carbon content in the solid phase was 5.5wt%;

[0038] Adjust the solid content of the silicon-rich slurry to 10wt%, according to the water content, add sodium hydroxide and dissolve it in water to make the concentration reach 10wt%; stir and age for 3 hours; the aging temperature is 80°C to obtain the precursor;

[0039] The obtained precursor was moved into a sealed reaction kettle for hydrothermal synthesis, and the crystallization temperature was 110°C; the crystallization time was 6 hours, then washed with water, and dried at 120°C; the obtained pro...

Embodiment 3

[0041] Weigh 100g coal gasification fine slag (wherein water content is 55%), add water and dilute to solid content is 20%, adopt high-speed dispersing mixer (Guangdong Foshan Yifu Machinery Co., Ltd.) to stir under normal temperature, stirring speed is 1500r / min, stirring time is 60min; the slurry was introduced into a cyclone separator for separation, and the obtained lower slurry was a silicon-rich slurry. After testing, the carbon content in the solid phase was 6.2wt%;

[0042] Adjust the solid content of the silicon-rich slurry to 5wt%, according to the water content, add sodium hydroxide and dissolve it in water to make the concentration reach 5wt%; add sodium sulfite with a molar ratio of 30% to iron oxide as a reducing agent, and stir and age for 3 hours ; The aging temperature is 80°C to obtain the precursor;

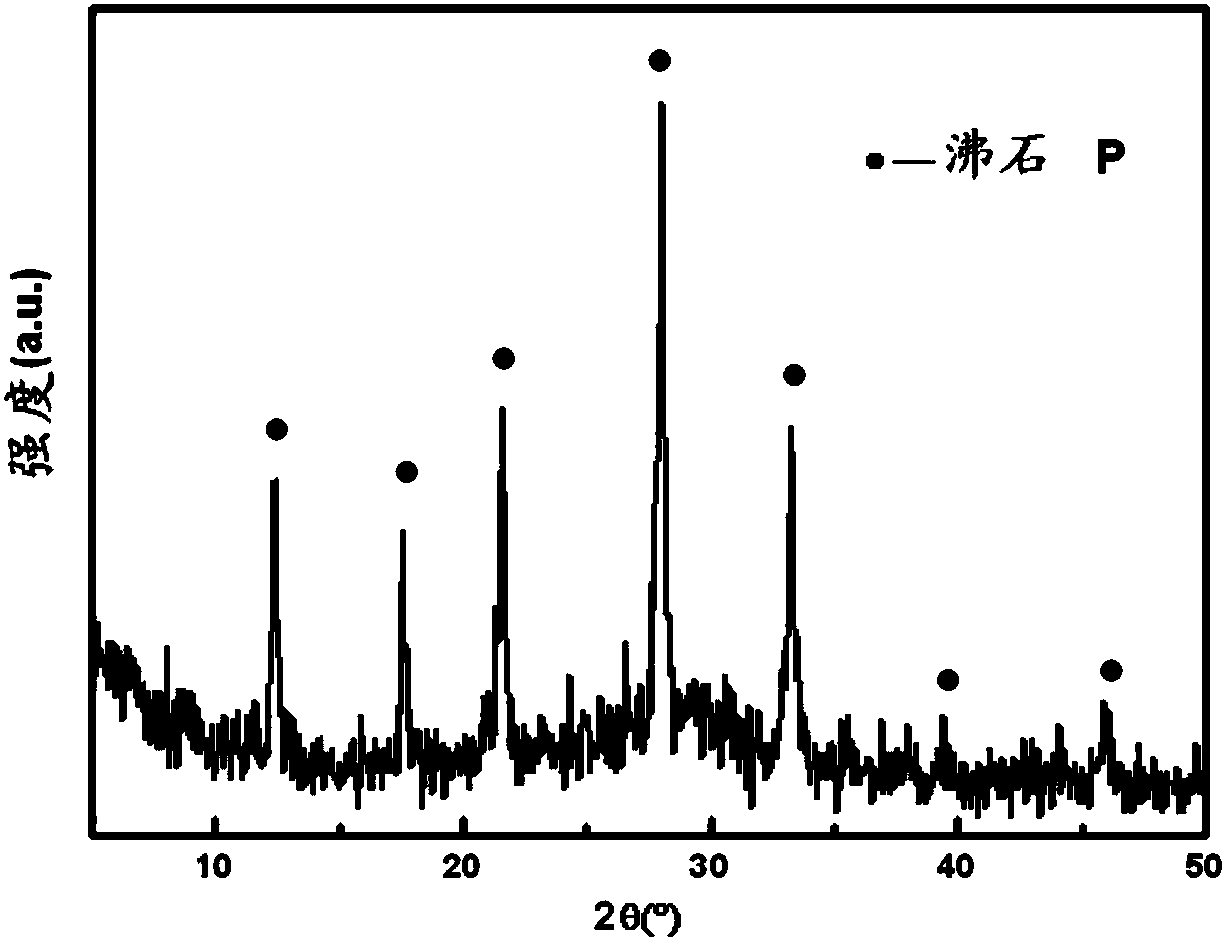

[0043] The obtained precursor was moved into a sealed reaction kettle for hydrothermal synthesis, the crystallization temperature was 120°C; the crystallizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com