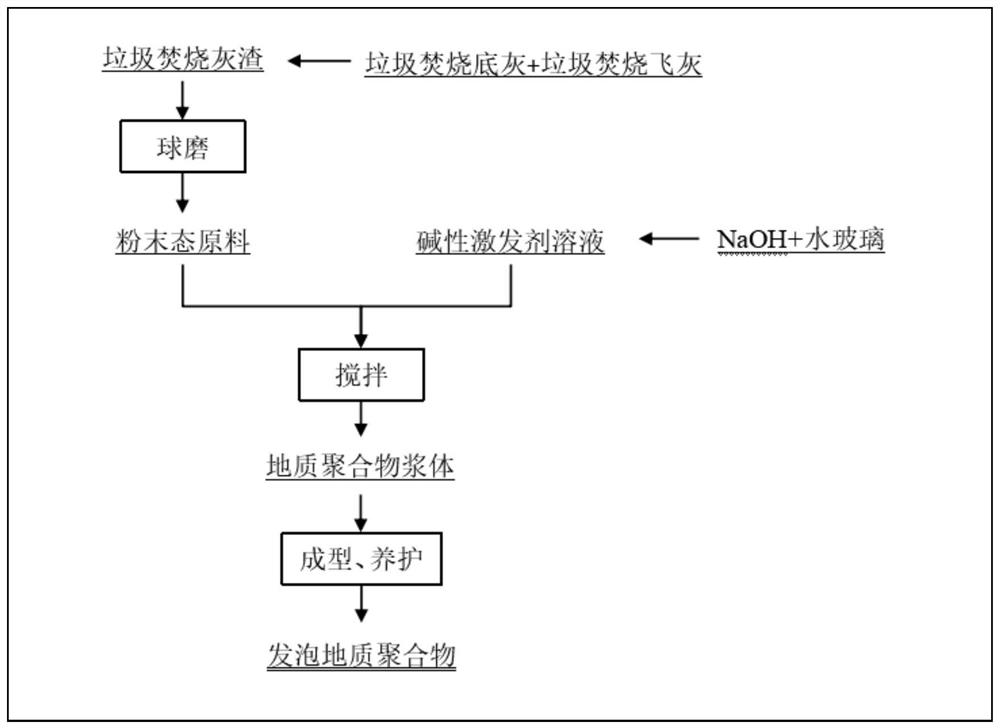

Method for preparing foam geopolymer from waste incineration ash

A waste incineration ash and geopolymer technology, which is applied in the production and application of ceramic products and cement, can solve the problems of serious environmental pollution, waste water pollution, large waste water production, etc., and achieve reduced environmental pollution, high economic benefits, and reduced The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The garbage incineration of the bottom ash and the fly as a mass ratio is 1: 1, and the ball mill mill is mined in the mechanical ball mill, and the ball milling speed is 300 rpm to obtain a mixture. The alkaline excitation agent and the mixture were stirred according to a mass ratio of 1: 1, wherein the basic excitation agent was prepared by the sodium glass and sodium hydroxide according to the mass ratio 2: 1, stirred at 500 rpm, stirring time 30 min, then The slurry was poured, at 80 ° C in the maintenance temperature, maintained for 12 h, the resulting foam geological polymer porosity was 56%, and the compressive strength was 2.1 MPa.

Embodiment 2

[0029] The garbage incineration underhead and fly as averages were 3: 1, and the ball milling mill was ground in the mechanical ball mill, and the ball milling speed 400 rpm was mixed. The alkaline excitation agent and the mixture were stirred according to the mass ratio of 1.5: 1, wherein the basic excitation agent was prepared by the sodium glass and sodium hydroxide according to the mass ratio of 5: 1, stirring the rotational speed of 1000 rpm, stirring time 5 min, then The slurry was poured, at 50 ° C in the maintenance temperature, and the obtained foam geological polymer porosity was 30%, and the compressive strength was 4.8 MPa.

Embodiment 3

[0031] The garbage incineration of the bottom ash and the fly as a mass ratio is 3: 1, and the ball milling mill is 20 h in a mechanical ball mill, and the ball milling speed is 500 rpm to obtain a mixture. The alkaline excitation agent and the mixture were stirred according to the mass ratio of 1: 1, wherein the alkaline excitation agent was prepared by the sodium glass and sodium hydroxide according to the mass ratio of 4: 1, stirring the rotational speed of 800 rpm, stirring time 20 min, then The slurry is poured, at 60 ° C in the maintenance temperature, 20 h, the resulting foam geological polymer porosity is 40%, and the compressive strength is 3.6 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com