Treatment method and implementation system for refuse incineration ash

A waste incineration ash and disposal method technology, applied in the direction of cement production, etc., can solve the problems of large water resources, consumption, and reduce the service life of refractory materials in the incinerator and cement kiln system, so as to facilitate grinding, complete combustion, decomposition and purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

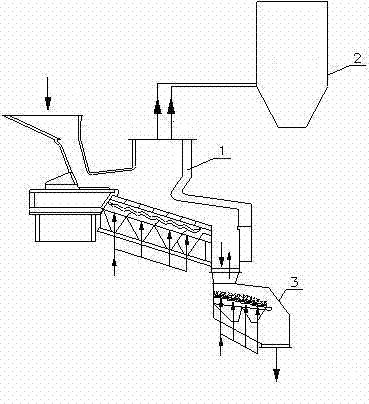

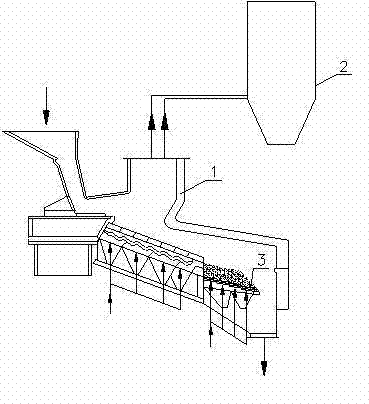

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

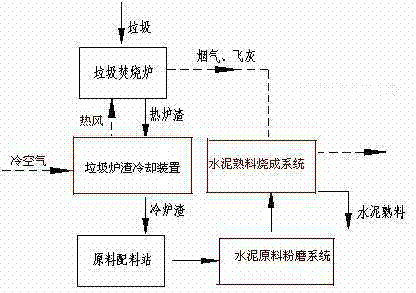

[0032] like Figure 1 to Figure 5 as shown, A method for disposing of waste incineration ash, Include the following steps:

[0033] Step 1: After the garbage is incinerated by the garbage incinerator 1, the fly ash enters the decomposition furnace of the cement clinker burning system along with the incineration flue gas and enters the cement kiln together with the raw material to burn into cement clinker;

[0034] Step 2: After the hot slag is discharged from the garbage incinerator 1, the cooling air is used for air cooling in the garbage slag cooling device 3. After heat exchange between the cold air and the hot slag, it becomes hot air and enters the garbage incinerator 1 for drying and drying of the garbage. Incineration use;

[0035] Step 3: The hot slag enters the raw material batching station through the air-cooled cold slag as cement raw material to partici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com