Hazardous waste treatment method and apparatus

A waste treatment, waste treatment system technology, applied in the field of industrial waste gas treatment or hazardous waste treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

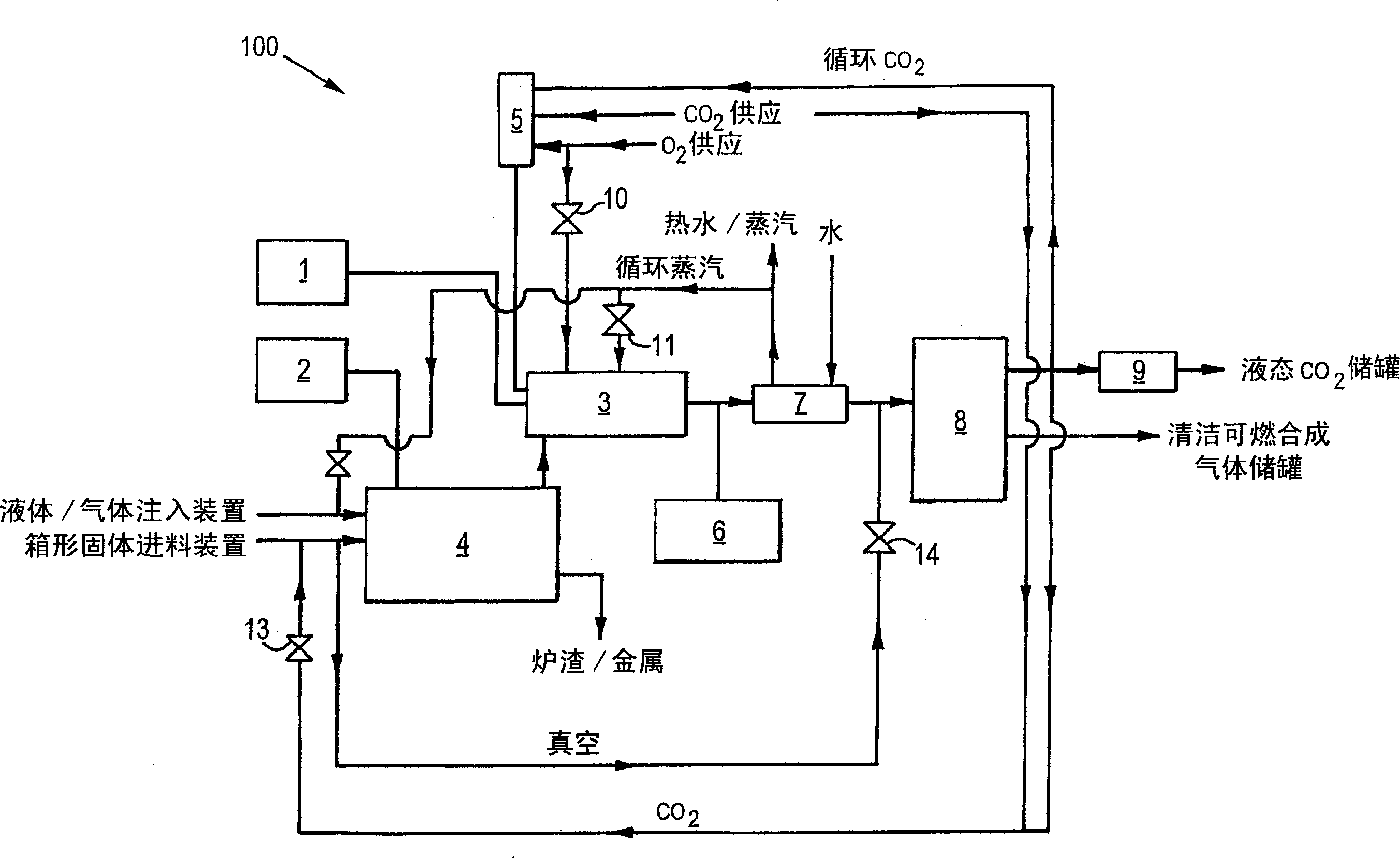

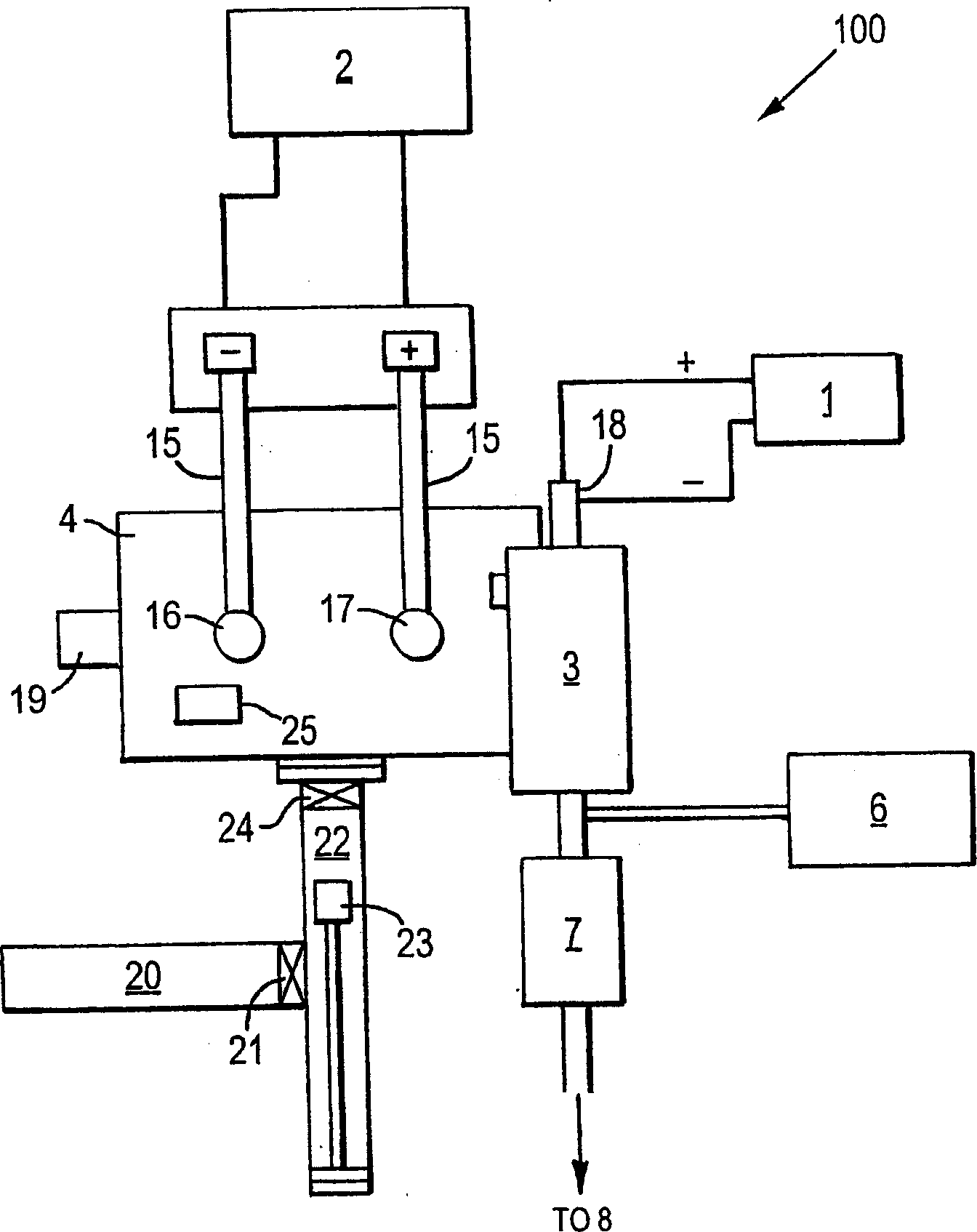

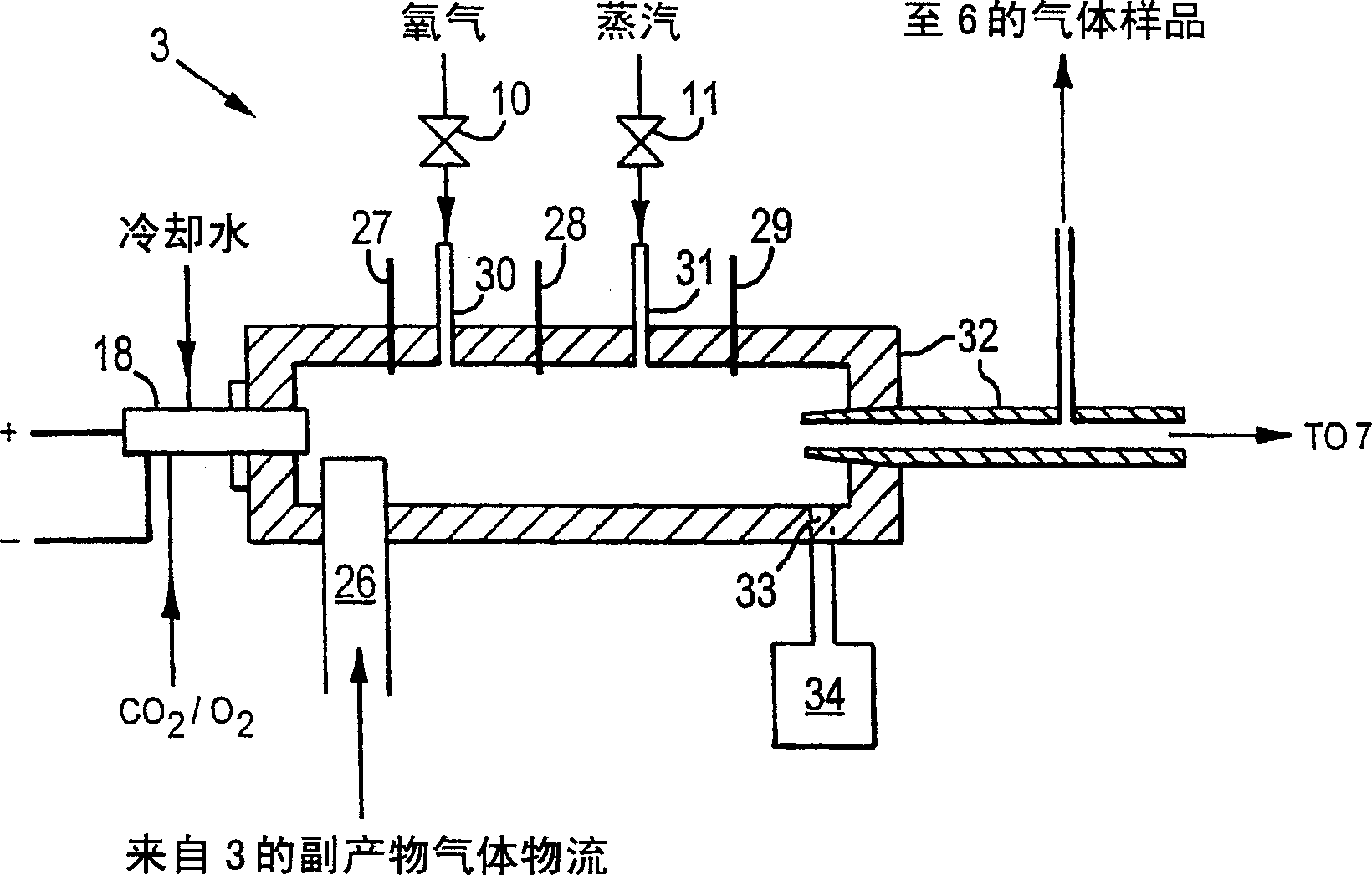

[0023] first reference figure 1 and figure 2 , figure 1 shows a diagram of the waste treatment system 100 of the present invention, while figure 2 A top down block diagram of waste treatment system 100 is shown. System 100 includes graphite electrode D.C. plasma arc gasifier / melter 4 and plasma torch cyclone oxidizer 3 . The waste material is introduced into the gasifier / melter 4 which melts the non-combustible material and decomposes the organic material. The off-gas from the gasifier / melter 4 is introduced into the cyclone oxidizer 3 . The cyclone oxidizer 3 then treats the exhaust gas according to the invention. The gasifier / melter 4 can also be considered a gasification / vitrification chamber.

[0024] The gasifier / melter 4 is preheated to above 1500°C by molten scrap steel in the gasifier / melter 4 before filling the hazardous waste into the gasifier / melter 4 of the graphite electrode D.C. arc for destruction temperature. The gasifier / melter 4 is refractory lined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com