Arsenic-containing neutralization slag solidifying and stabilizing agent and method for solidifying and stabilizing arsenic-containing neutralization slag by using same

A stabilizer and curing agent technology, which is applied in the direction of cement production, etc., can solve the problems of unrealized final disposal, difficulty in mixing uniformly in the curing process, complicated operation, etc., and achieve harmless disposal, good curing effect, and easy popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Raw material 1: neutralized slag containing arsenic

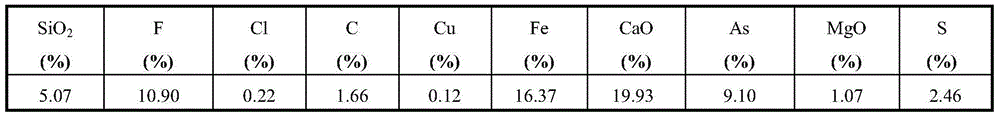

[0041] The main components of the arsenic-containing neutralization slag are shown in the following table:

[0042] Table 1 Analysis results of chemical composition of arsenic-containing neutralization slag in a factory

[0043]

Embodiment approach

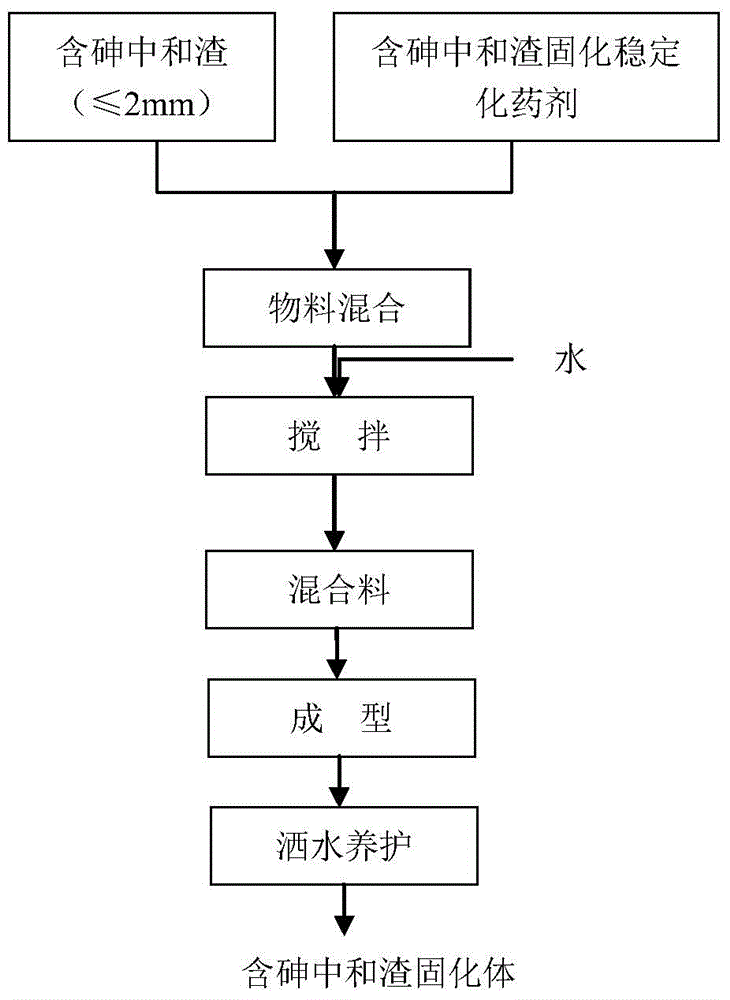

[0045] The method for solidifying and stabilizing the neutralized slag containing arsenic in the present embodiment (process flow chart is as follows figure 1 shown) includes the following steps:

[0046] (1) Naturally air-dry the arsenic-containing neutralized slag and then go through a ball mill for ball milling before use. The particle size of the arsenic-containing neutralized slag is less than or equal to 2mm;

[0047] (2), take by weighing the raw material in the ratio of cement 50%, fly ash 30%, lime 9% and ferrous sulfate 11% by weight percentage of each composition in the curing stabilizing agent;

[0048] (3), mix the arsenic-containing neutralization slag and the solidification stabilizing agent according to the ratio of 52%: 48%, and stir to obtain the mixed dry material; then add 30% water of the mixed dry material to the mixed dry material, After stirring for 10-15 minutes, the mixture is obtained and sent to the brick making system for molding;

[0049] (4) The...

Embodiment 2

[0055] Raw material 2: neutralized slag containing arsenic

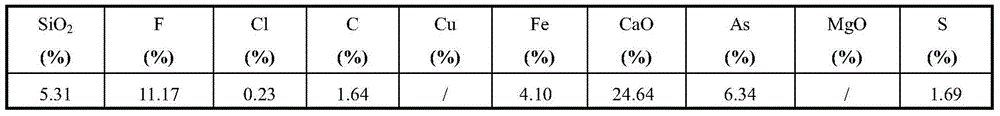

[0056] The main components of the arsenic-containing neutralization slag are shown in the following table:

[0057] Table 3 Analysis results of chemical composition of arsenic-containing neutralization slag in a factory

[0058]

[0059] method of execution:

[0060] The method for solidifying arsenic-containing neutralization slag in the present embodiment (process flow chart is as follows figure 1 shown) includes the following steps:

[0061] (1) Naturally air-dry the arsenic-containing neutralized slag and then carry out ball milling treatment in a ball mill for later use. The particle size of the arsenic-containing neutralized slag is ≤2mm;

[0062] (2) take the raw material according to the ratio of cement 48%, fly ash 35%, lime 6% and ferrous sulfate 11% by weight percentage of each composition in the curing and stabilizing agent;

[0063] (3) Mix the arsenic-containing neutralization slag and the curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com