Waste cutting fluid treatment process

A waste cutting fluid and treatment process technology, which is applied in the field of waste cutting fluid treatment process, can solve the problems of high operating pressure, high operating cost, and complicated process, and achieve the effects of low treatment cost, good effect, and stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

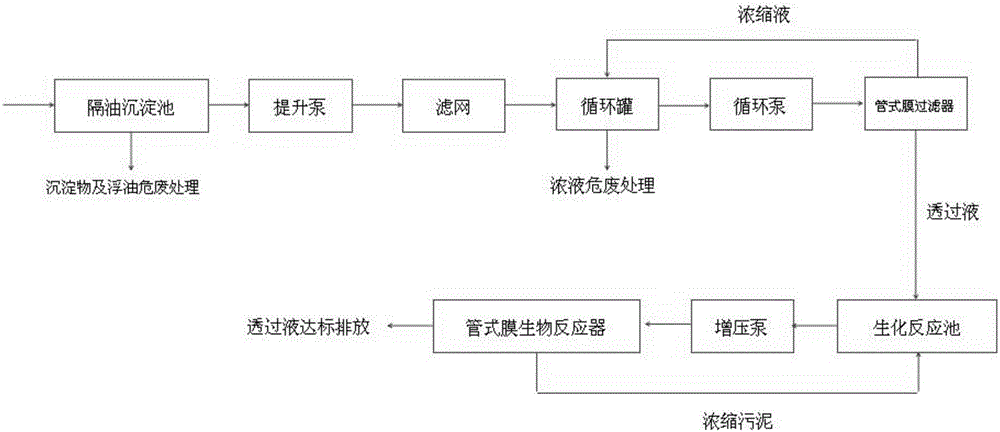

[0021] see figure 1 , the process of the present invention includes the following flow process,

[0022] 1) The waste cutting fluid enters the oil-separating sedimentation tank for sedimentation and oil-separation. Large and heavy metal particles sink to the bottom of the tank, and lighter oil floats on the liquid surface and is removed separately;

[0023] 2) The effluent from the oil-separating sedimentation tank is filtered by the lift pump through the filter to remove the smaller metal particles in the cutting fluid, and then enters the circulation tank. The mesh size of the filter is 0.1-1mm;

[0024] 3) The effluent of the circulation tank is lifted by the circulation pump and enters the tubular membrane filter for oil removal and filtration. The permeate of the tubular membrane filter ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com