Industrial liquid hazardous waste treatment system

A treatment system and liquid technology, applied in the direction of heating water/sewage treatment, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as failure to deal with in time, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings. Any similar processing flow and similar changes of the present invention should be included in the protection scope of the present invention.

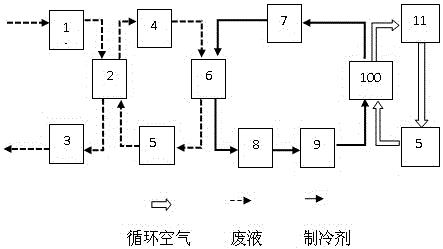

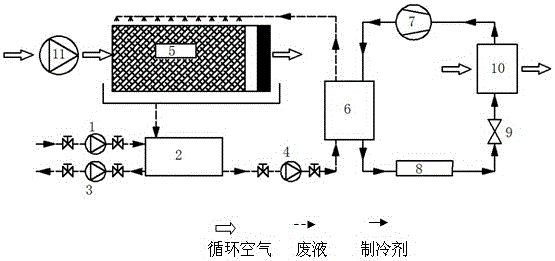

[0020] Such as figure 1 , figure 2 As shown, an industrial liquid hazardous waste treatment system is characterized in that it consists of three parts: an air circulation treatment microsystem, a waste liquid concentration treatment microsystem and a heat pump circulation microsystem.

[0021] The air circulation processing microsystem is composed of a fan 11, an air and waste liquid concentration processor 5 and an air / refrigerant heat exchanger 10;

[0022] The waste liquid concentration treatment microsystem consists of a waste liquid storage tank 2, a waste liquid circulation pump 4, a waste liquid discharge pump 3, a waste liquid inlet pump 1, a waste liquid / refrigerant heat exchanger 6, and air and waste liquid Concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com