Stabilizing agentia used for treating waste residue containing beryllium and preparation method and application thereof

A stabilization and waste slag technology, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of no special stabilizer for beryllium-containing waste slag, no beryllium-containing waste slag, etc., to achieve the preparation method and The method of use is simple, the cost is low, and it is beneficial to the effect of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The stabilizer agent for treating waste residue containing beryllium comprises the following components in parts by mass: 15 parts of fly ash and 85 parts of portland cement.

[0022] The preparation method of the stabilizing agent for treating beryllium-containing waste slag is as follows: uniformly mix the fly ash and portland cement according to the mass ratio to obtain the finished product.

Embodiment 2

[0024] The stabilizer agent for treating waste residue containing beryllium comprises the following components in parts by mass: 25 parts of sepiolite and 75 parts of portland cement.

[0025] The preparation method of the stabilizing agent for treating beryllium-containing waste slag is as follows: uniformly mix the sepiolite and Portland cement according to the mass ratio to obtain the finished product.

Embodiment 3

[0027] The stabilizer agent for treating beryllium-containing waste slag includes the following components in parts by mass: 20 parts of waterworks sludge and 80 parts of portland cement.

[0028] The preparation method of the stabilizing agent for treating beryllium-containing waste slag is as follows: according to the mass ratio, uniformly mix the residual sludge of the water supply plant with Portland cement to obtain the product.

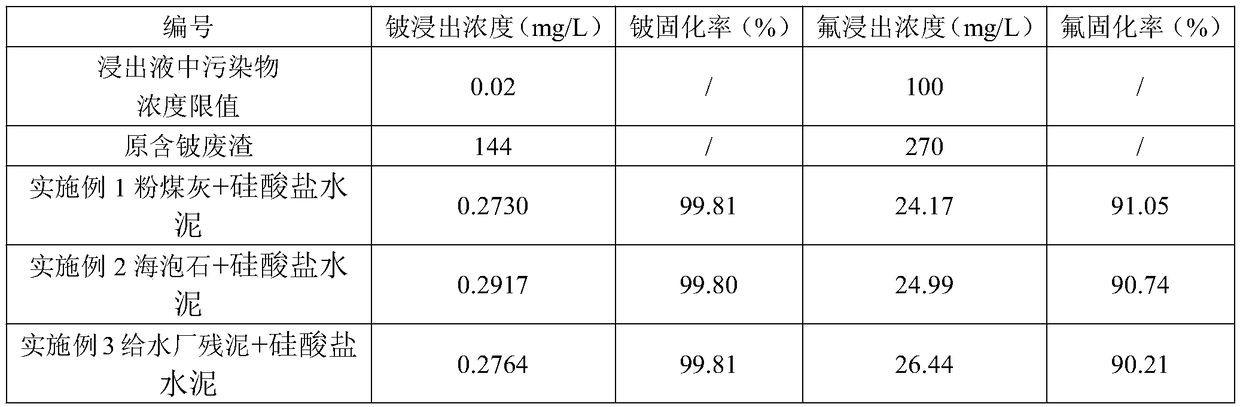

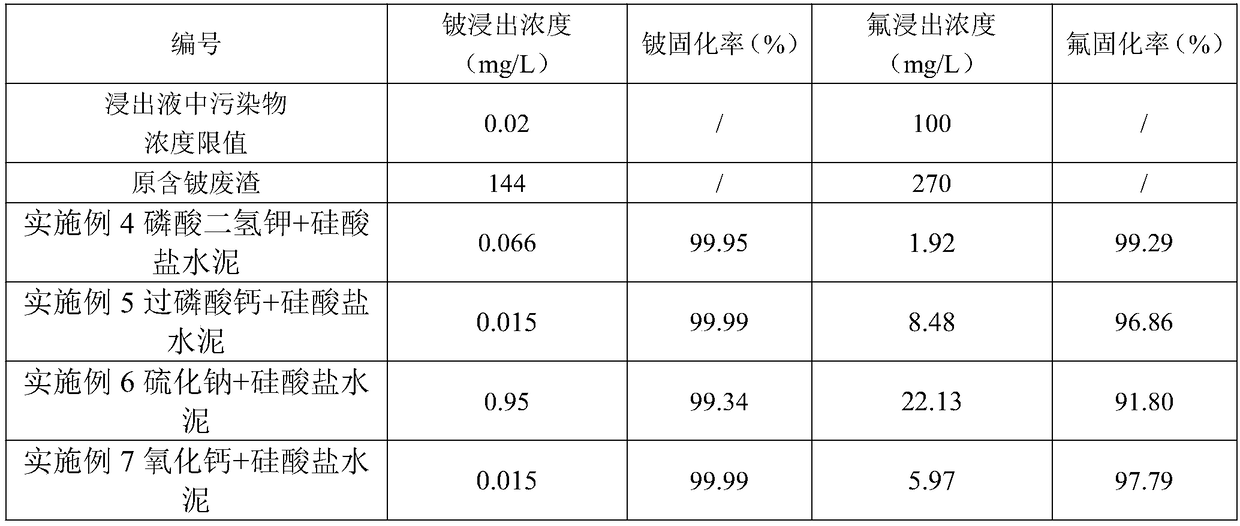

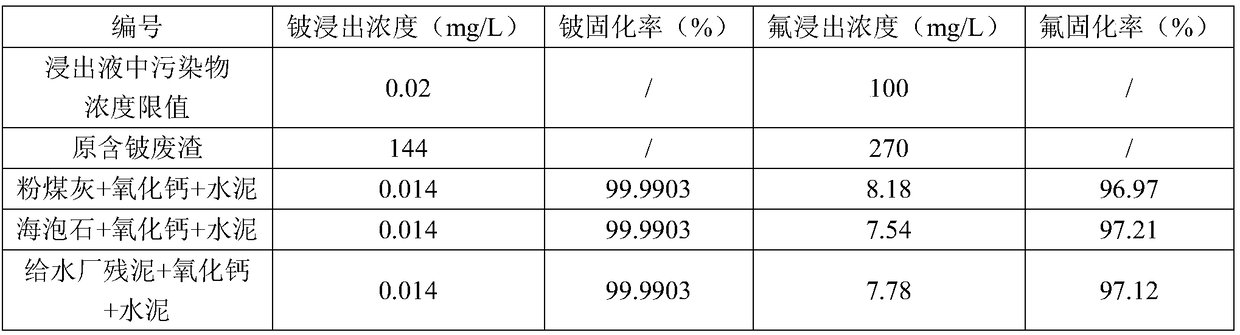

[0029] Stabilization treatment of waste slag containing beryllium was carried out by using the stabilizing agents in Examples 1 to 3 respectively. Take the beryllium-containing waste slag particles that are broken into particle size ≤ 0.3mm after drying, wherein the beryllium content is 3500mg / kg, and the fluorine content is 40400mg / kg. Mix the stabilizing agents obtained in Examples 1 to 3 with the beryllium-containing waste residue at a mass ratio of 0.8:1, and after uniform mixing, add water at a solid-to-liquid ratio of 1: (0.5 to 0.8) and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com