Waste incineration fly ash treatment and recycling method and device

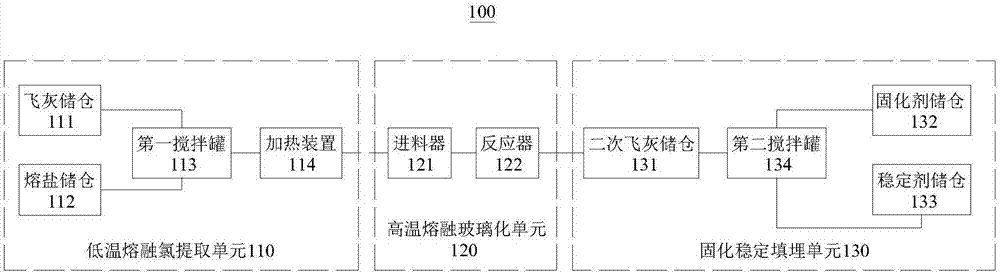

A waste incineration fly ash and recycling technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve the problems of high capacity increase ratio, large land occupation, etc., and achieve a high degree of harmlessness , easy to promote, and obvious effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for waste incineration fly ash treatment and resource utilization, which is carried out according to the following process:

[0041] Take 5000g of fly ash mixture (waste incineration fly ash) during normal operation of a certain waste incineration power plant in Wuhan, add halides of alkaline earth metals with 80% of the mass of the fly ash mixture as molten salt, heat in an electric furnace at 600°C, and melt at low temperature for 60min, A liquid product in the upper layer and a solid product in the lower layer were obtained.

[0042] Part of the upper liquid product is recycled as molten salt, and part of it is cooled as industrial salt raw material to prepare industrial salt; the lower solid product is mixed with coal powder, quartz sand, and anorthite and sent to the combustion furnace for high temperature melting at 1400°C. The volatilized secondary fly ash is collected, and the bottom slag is cooled and used as glass raw material...

Embodiment 2

[0045] This embodiment provides a method for waste incineration fly ash treatment and resource utilization, which is carried out according to the following process:

[0046] Take 5000g of fly ash mixture (waste incineration fly ash) during normal operation of a certain waste incineration power plant in Wuhan, add alkali metal nitrate with 75% of the quality of the fly ash mixture as molten salt, heat in an electric furnace at 550°C, and melt at low temperature for 80min. A liquid product in the upper layer and a solid product in the lower layer were obtained.

[0047] A part of the liquid product in the upper layer is recycled as molten salt, and a part is cooled to prepare polyvinyl chloride; the solid product in the lower layer is mixed with coke, anorthite, and quicklime and sent to the combustion furnace, where it is melted at a high temperature of 2000 ° C to capture the volatilized secondary fly Ash and bottom slag are used as glass raw materials to make glass drawing in...

Embodiment 3

[0050] This embodiment provides a method for waste incineration fly ash treatment and resource utilization, which is carried out according to the following process:

[0051] Take 5000g of fly ash mixture (waste incineration fly ash) at different periods during normal operation of a certain waste incineration power plant in Wuhan, add alkaline earth metal sulfate with 85% of the quality of the fly ash mixture as molten salt, heat in an electric furnace at 700°C, and melt at low temperature for 50min. A liquid product in the upper layer and a solid product in the lower layer were obtained.

[0052] Part of the liquid product in the upper layer is recycled as molten salt, and part of it is cooled to prepare molten salt; the solid product in the lower layer is mixed with fuel oil, quartz sand, and quicklime and sent to the furnace for melting at a high temperature of 3000°C to capture volatilized secondary fly ash. After cooling, the bottom slag is used as glass raw material to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com